13

Installation and Set-Up (Continued)

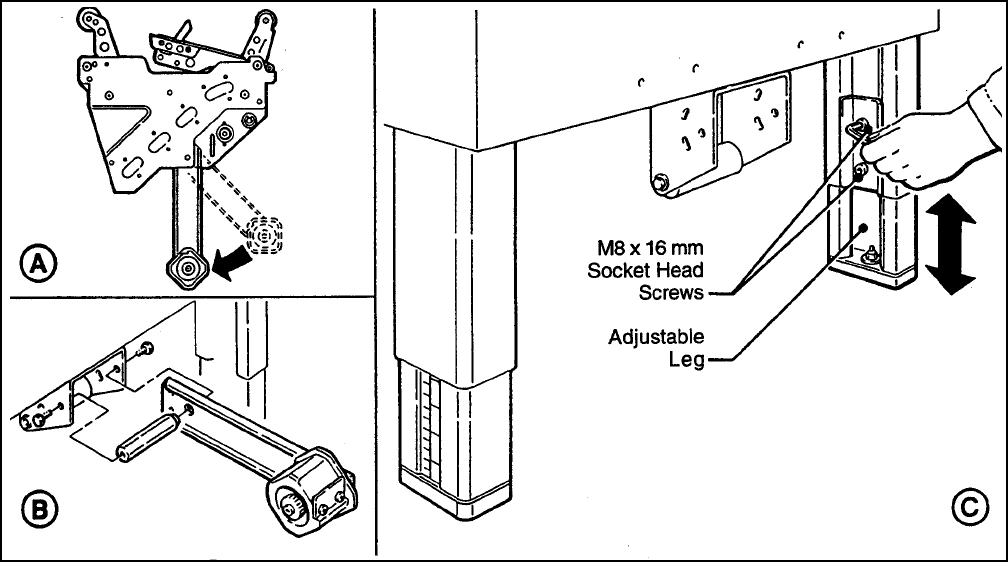

TAPE DRUM BRACKET (Lower Taping Head)

Outboard tape roll mounting

(Alternate Position)

–

Remove the tape drum bracket assembly, stud

spacer and fasteners from the taping head.

Install and secure on the infeed end of the lower

frame, as shown in Figure 2-2B.

TAPE WIDTH

The taping heads on the 800a3 have been pre-

set to accommodate 72 mm [3 inch] wide tape

rolls. To adjust heads for narrower tape, refer to

Section

II

, "Adjustments – Tape Web

Alignment", page 11.

MACHINE BED HEIGHT

Adjust machine bed height. The case sealer is

equipped with four adjustable legs that are

located at the corners of the machine frame.

The legs can be adjusted to obtain different

machine bed heights from 610 mm [24 inches]

minimum to 890 mm [35 inches] maximum.

Refer to Figure 2-2C and set the machine bed

height as follows:

1. Raise and block up the machine frame to

allow adequate leg adjustment.

2. Loosen, but do not remove, two M8 x 16

socket head screws in one leg (use M6 hex

wrench). Adjust the leg length for the

desired machine bed height. Retighten the

two screws to secure the leg. Adjust all four

legs equally.

BOX SIZE CAPACITY OF CASE SEALER

At its factory setting, the case sealer handles

box sizes up to 620 mm [24-1/2 inches]

maximum height. If larger capacity is needed,

the machine can be adjusted to accommodate

boxes up to 725 mm [28-1/2 inches] high. Refer

to page 27,

"Special Set-Up Procedures – Box

Height Range", for set-up procedure.

Note – Adjusting machine to accommodate

724 mm [28-1/2 inches] high boxes also

increases minimum box size to 210 mm

[8-1/4 inches].

TAPE LEG LENGTH

Taping heads are pre-set to apply 70 mm

[2-3/4 inch] long tape legs. To change tape legs

to 48 mm [2 inch], see "Special Set-Up

Procedure – Changing Tape Leg Length",

page 25.

Figure 2-2 – Machine Bed Height Adjustment and Lower Tape Drum Bracket Position