18

Operation (Continued)

3 Emergency "Stop" Switch

The two emergency "Stop" switches are

mounted for operator convenience, on both

sides of the case sealer. Pushing either of

these switches will stop the drive motors/belts

and exhaust air from the flap kicker.

To restart machine, rotate emergency stop

switch (release switch latch) and then restart

machine by pressing green (On) button on side

guard.

4 Height Adjustment Crank, Upper

Taping Head

Raises and lowers upper taping head/flap

folders to accommodate box height.

5 Width Adjustment Crank

Adjusts distance between side drive belts to

accommodate box width.

6 Top Flap Compression Rollers

Rollers adjust to properly maintain box width/

top flap center seam for tape seal.

7 Indicator, Air Pressure

The optical warning indicator, located on the

upper flap folder frame, indicates "Red" when

compressed air circuit is on.

8 Box Gate Air Pressure Regulator

Adjusts lifting force of the box gate depending

on the weight of boxes being sealed.

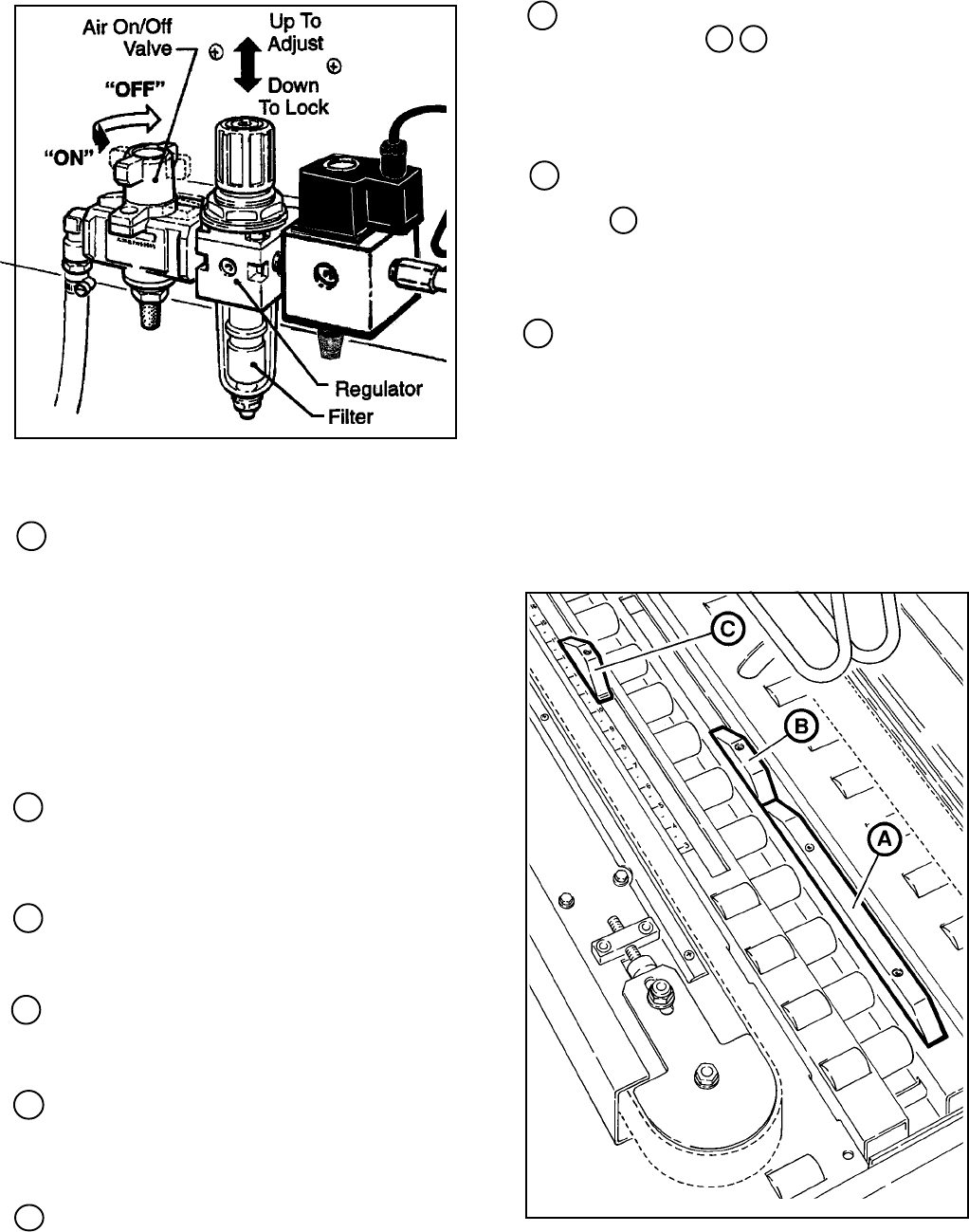

9 Gate Cams Figure 3-4

The gate cams A B control the rate of box

entry into the case sealer. Depending on box

size, gate cams can be adjusted to increase

production rate. See "Adjustments – Gate

Operation".

10 Kicker Cam Figure 3-4

The minor flap folder, controlled by the kicker

cam C , closes the trailing minor flap on the

box. The kicker cam must be adjusted

according to the length of the box being

sealed. See "Operation" Figure 3-8.

11 Pocket, Instruction Manual

A pocket is provided inside the right door for

storage of the machine instruction manual.

Keep the manual in this pocket for the

convenience of machine operators.

Figure 3-4 – Gate/Kicker Cams

Figure 3-3 – "On/Off" Valve/Regulator/Filter