34

Special Set-Up Procedure

Changing Drive Belt Height

The drive belt assemblies can be raised 50 mm

[2 inches] to provide better conveying of tall boxes.

This change increase the minimum box height

that can be taped to 190 mm [7-1/4 inches].

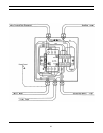

DISASSEMBLY – Figure 6-1

1. Using the height adjustment crank, raise the

upper taping head to its fully raised position.

2. Remove and retain the M6 x 16 flat head cap

screw (A), special washer (B) and spacer (C)

from the front and rear arm assembly pivots.

3. Lift drive belt assembly (D) up off the arm

assembly pivots.

Note – Keep motor in vertical position to

prevent gear oil from leaking out of motor.

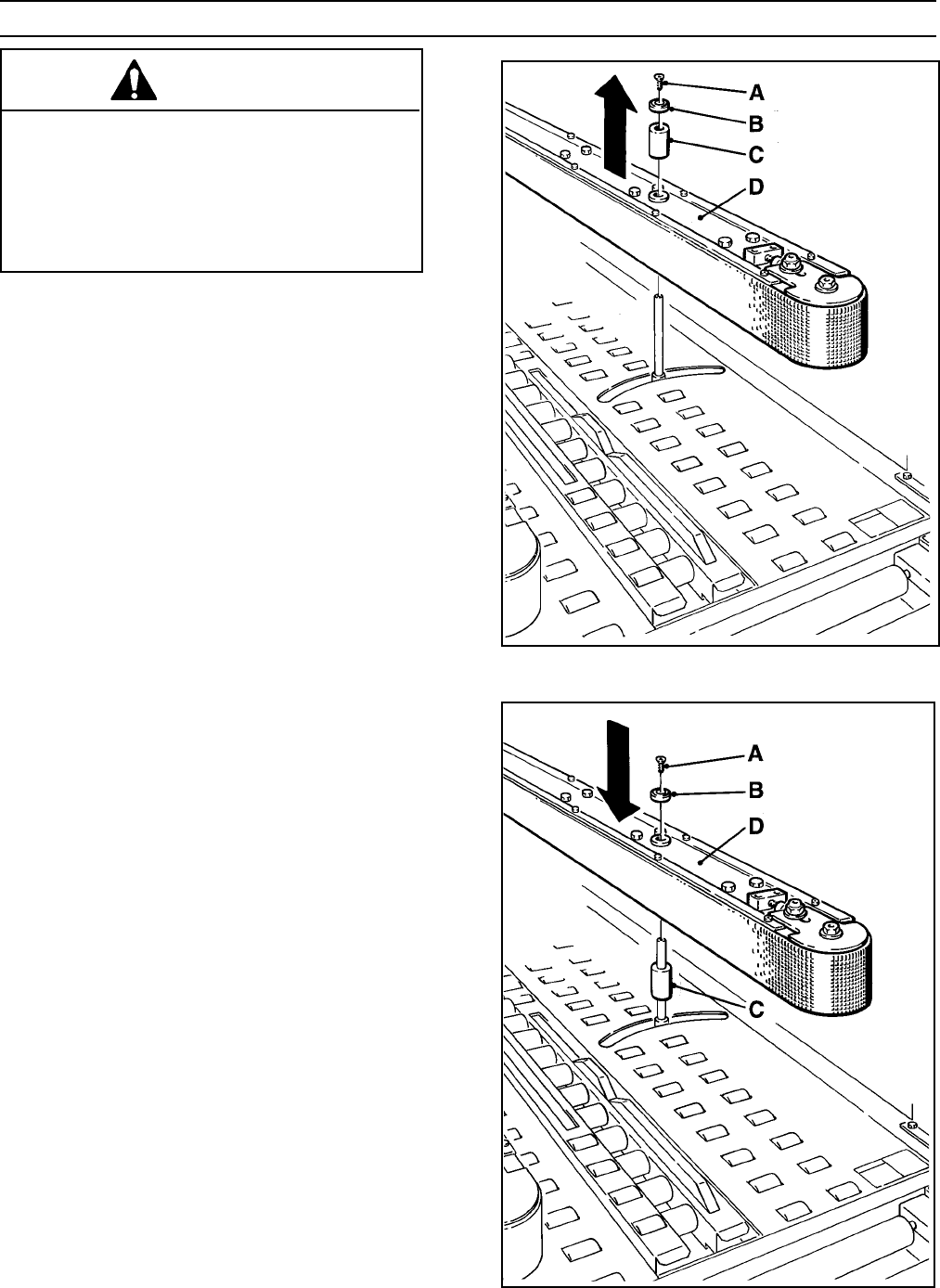

REASSEMBLY – Figure 6-2

4. Reassemble the spacer (C) onto the front and

rear arm assembly pivots first.

5. Install the belt drive assembly (D) onto the

pivots and secure with special washers (B) and

M6 x 16 flat head cap screws (A).

Note – Both drive belt assemblies must be

installed at the same operating height.

Figure 6-1 – Drive Belt Height, Disassembly

Figure 6-2 – Drive Belt Height, Reassembly

• To reduce the risk associated with

mechanical and electrical hazards:

– Turn electrical and air supply off and

disconnect before performing any

adjustments, maintenance or servicing the

machine or taping heads

WARNING