11

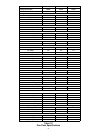

Figure 3

Proper Piping Practice

Checking The Gas Piping

CAUTION

To avoid the possibility of personal in-

jury, property damage or fire, the follow-

ing instructions must be performed re-

garding gas connections and pressure

testing:

• This unit and its gas connections must

be leak tested before placing in opera-

tion. Because of the danger of explosion

or fire, never use a match or open flame

to test for leaks. Never exceed speci-

fied pressures for testing. Higher pres-

sure may damage gas valve and cause

overfiring which may result in heat fail-

ure.

• This unit and shut-off valve must be dis-

connected from the gas supply during

any pressure testing of that system at

test pressures in excess of 1/2 PSIG

(3.48 kPa).

• This unit must be isolated from the gas

supply system by closing the manual

shut-off valve during any pressure test-

ing of the gas supply piping system at

test pressures equal to or less than 1/2

PSIG (3.48 kPa).

WARNING

To avoid personal injury or property dam-

age, be sure there is no open flame in the

vicinity during air bleeding procedure.

There will be air in the gas supply line after testing for

leaks on a new installation. Therefore, the air must be

bled from the line by cracking open the ground joint union

until pure gas is expelled. Tighten union and wait for

five minutes until all gas has been dissipated in the air.

Be certain there is no open flame in the vicinity during

air bleeding procedure. The unit is placed in operation

by closing the main electrical disconnect switch for the

furnace.

Tanks And Piping for Propane Gas Units

WARNING

Personal Injury Hazard

Failure to detect a propane gas leak could

result in an explosion or fire which could

cause death, serious personal injury, or

property damage.

Iron oxide (rust) can reduce the level of

odorant in propane gas. A gas detecting

device is the only reliable method to de-

tect a propane gas leak. Contact the lo-

cal propane supplier about installing a

warning device to sound an alert if a gas

leak should develop.

All propane gas equipment must conform to the safety

standards of the National Board of Fire Underwriters (See

NBFU Manual 58).

For satisfactory operation, propane gas pressure must

be 10 inch W.C. at the furnace manifold with all gas ap-

pliances in operation. Maintaining proper gas pressure

depends on three main factors:

1. Vaporization rate, which depends on (a) tempera-

ture of the liquid, and (b) wetted surface area of the

container or containers.

2. Proper pressure regulation. (Two-stage regulation

is recommended from the standpoint of both cost

and efficiency.)

3. Pressure drop in lines between regulators, and be-

tween second stage regulator and the appliance.

Pipe size required will depend on length of pipe run

and total load of all appliances.

Complete information regarding tank sizing for vapor-

ization, recommended regulator settings and pipe siz-

ing is available from most regulator manufacturers and

propane gas suppliers.