30

12. Shut off main water valve. Remove and save the extended length 3/8” outside diameter (O.D.) tubing for

future cleanings. Reattach the original 3/8” O.D. tubing to the sampling valve cluster. Open main water

valve.

13. Reset the microprocessor.

14. Wait 24 to 48 hours and measure the base flow rate of the cleaned membrane as detailed in step #1 through

step #5 (refer to Product Water Flow Rate Measurement on pages 23 and page 24). The new base

flow should be similar to the original one (1). If not, alkaline cleaning should be performed. The procedure

for alkaline cleaning is the same as for acid cleaning except an alkaline cleaning cartridge is used instead.

C. STORAGE and SHIPPING OF MEMBRANE

ATTENTION: IF THE MEMBRANE IS TO BE SHIPPED or IF THE MACHINE IS TO BE

LEFT IDLE FOR FIVE (5) DAYS or MORE, PRESERVATIVES MUST BE

ADDED TO THE REVERSE OSMOSIS (R.O.) MEMBRANE TO KEEP IT

MOIST and FREE FROM BACTERIAL GROWTH.

WARNING: CHLORINE WILL IRREPARABLY DAMAGE THE R.O. MEMBRANE.

1. Vend 6 gallons (22.71 liters) of water into a container for mixing the preservative solution. Remember this

water is going into the R.O. membrane and cannot contain chlorine. Water from the sampling valve

AFTER the carbon filter is also acceptable.

WARNING: OBSERVE ALL RELEVANT PRECAUTIONS WHEN HANDLING

CHEMICALS. WEAR PROTECTIVE CLOTHING, GLOVES and EYE

PROTECTION.

2. Disconnect electrical power to the machine.

3. Shut off main water valve at the inlet of the machine.

4. Relieve pressure in the system by opening the sampling valve after the carbon filter. Close it after flow

stops.

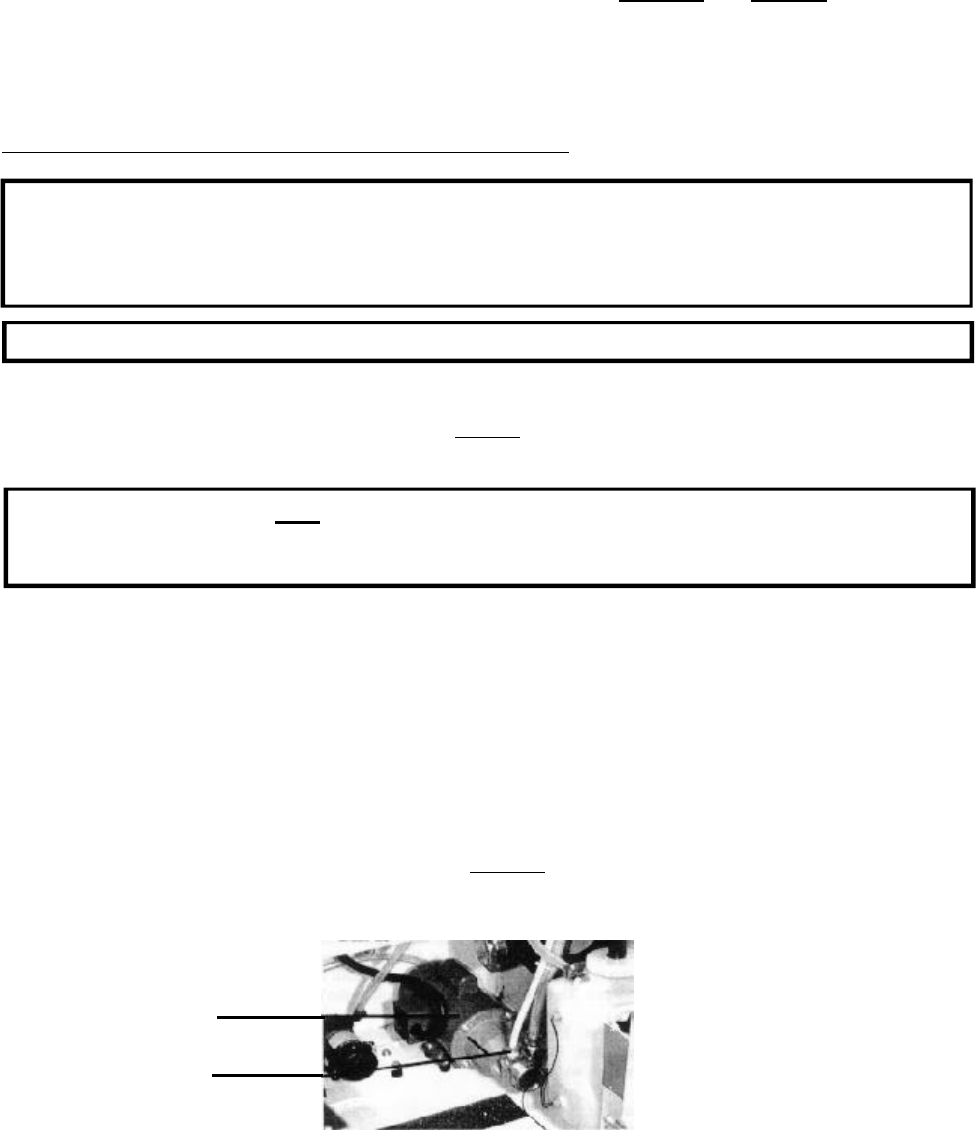

5. Disconnect 1/2” O.D. tubing at the outlet of the R.O. pump (refer to diagram 13) and at the inlet of the

back pressure regulator (refer to diagram 14 on page 31). Disconnect the tubing by depressing the ring on

the fitting and then pulling at the tubing. Water will begin to flow out from the bottom tubing. Drain the R.O.

housing of water.

R.O. Pump

Outlet

DIAGRAM 13