For adequate and long-lasting machinesupport, proper grout

selection and placement is essential. Carrier recommends that

only epoxy-type grout be used for machine installation. Fol-

low manufacturer’s instructions in applying grout.

1. Check machine location prints for required grout

thickness.

2. Carefully wax jacking screws for easy removal from grout.

3. Grout must extend above the base of the soleplate and

there must be no voids in grout beneath the plates.

4. Allow grout to set and harden, per manufacturer’s in-

structions, before starting machine.

5. Back jacking screws off leveling pads after grout has

hardened.

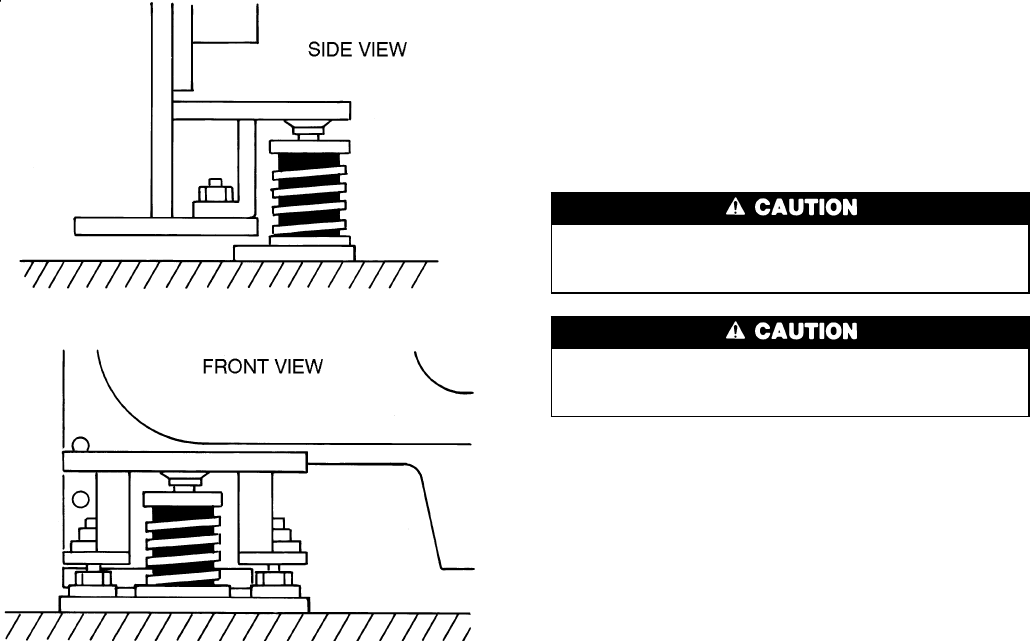

INSTALL SPRING ISOLATION — Field-supplied spring

isolators may be placed directly under machine support plates

or located under machine soleplates. See Fig. 17. Consult

job data for specific arrangement. Low profile spring isola-

tion assemblies are recommended so that the machine is kept

at a convenient working height inside of the tube sheet.

Obtain specific details on spring mounting and machine

weight distribution from job data. Also, check job data for

methods for supporting and isolating pipes that are attached

to the spring isolated machines.

Connect Piping

INSTALL WATER PIPING TO HEAT EXCHANGERS —

Install piping using job data, piping drawings, and proce-

dure outlined below. A typical piping installation is shown

in Fig. 19.

Factory-supplied insulation is not flammable but can be

damaged by welding sparks and open flame. Protect in-

sulation with a wet canvas cover.

Remove chilled and condenser water sensorsbefore weld-

ing connecting piping to water nozzles. Refer to Fig. 2

and 3. Replace sensors after welding is complete.

1. If the machine is a nozzle-in-head arrangement, offset pipe

flanges to permit removal of waterbox cover for main-

tenance and to provide clearance for pipe cleaning. No

flanges are necessary with marine waterboxes; however,

water piping should not cross in front of the waterbox or

access will be blocked off.

2. Provide openings in water piping for required pressure

gages and thermometers. Openings should be at least 6 to

10 pipe diameters from the waterbox nozzle. For thor-

ough mixing and temperature stabilization, wells in the

leaving water pipe should extend inside pipe at least

2 in. (50 mm).

3. Install air vents at all high points in piping to remove air

and prevent water hammer.

4. Install pipe hangers where needed. Make sure no weight

or stress is placed on waterbox nozzles or flanges.

5. Water flow direction information is shown in Fig. 20 and

21.

NOTE: Entering water is always the lower of the two

nozzles. Leaving water isalways the upper nozzle for cooler

or condenser.

6. Water flow switches must be of vapor-tight construction

and must be installed on top of the pipe in a horizontal

run and at least 5 pipe diameters from any bend.

Differential pressure type flow switches may be con-

nected at the nozzle of the waterbox.

7. Install waterbox vent and drain piping in accordance with

individual job data. All connections are

3

⁄

4

-in. FPT.

8. Install waterbox drain plugs in the unused waterbox drains

and vent openings.

9. Install water piping to the optional pumpout system con-

denser storage tank as shown in Fig. 20-25.

NOTE:Afield suppliedand installed lowprofile isolation issuggested

to keep operation height low.

Fig. 18 — Typical Low Profile Isolation Assembly

(Field Supplied and Installed)

18