CONTENTS

Page

SAFETY CONSIDERATIONS ...................1

INTRODUCTION ..............................2

General ......................................2

Job Data ....................................2

Equipment Required .........................2

INSTALLATION .............................2-34

Receiving the Machine .......................2

• INSPECT SHIPMENT

• IDENTIFY MACHINE

• PROVIDE MACHINE PROTECTION

Rigging the Machine .........................4

• RIG MACHINE ASSEMBLY

• RIG MACHINE COMPONENTS

Install Machine Supports ....................16

• INSTALL STANDARD ISOLATION

• INSTALL OPTIONAL OR ACCESSORY

ISOLATION

• INSTALL SPRING ISOLATION

Connect Piping .............................18

• INSTALL WATER PIPING

TO HEAT EXCHANGERS

• INSTALL VENT PIPING

TO RELIEF DEVICES

Make Electrical Connections .................25

• CONNECT CONTROL INPUTS

• CONNECT CONTROL OUTPUTS

• CONNECT STARTER

• INSULATE MOTOR TERMINALS

AND LEAD WIRE ENDS

• CONNECT POWER WIRE TO OIL

HEATER CONTACTOR (Frame 1 and 2)

• CONNECT COMMUNICATION AND CONTROL

WIRING FROM STARTER TO POWER PANEL

• CARRIER COMFORT NETWORK

INTERFACE

Install Field Insulation .......................30

• FACTORY-INSTALLED INSULATION

INSTALLATION START-UP REQUEST

CHECKLIST ..........................CL-1, CL-2

INTRODUCTION

General —

The 23XLmachine is factory assembled, wired,

and leak tested. Installation (not by Carrier) consists prima-

rily of establishing water and electrical services to the ma-

chine. Rigging, installation, field wiring, and field piping are

the responsibility of the contractor and/or customer. Carrier

has no installation responsibilities for the equipment.

Job Data

Necessary information consists of:

• job contract or specifications

• machine location prints

• rigging information

• piping prints and details

• field wiring drawings

• starter manufacturer’s installation details

• Carrier certified prints

Equipment Required

• mechanic’s tools (refrigeration)

• volt-ohmmeter and clamp-on ammeter

• leak detector (halide or electronic)

• absolute pressure manometer or wet-bulb vacuum

indicator

• portable vacuum pumps

INSTALLATION

Receiving the Machine

INSPECT SHIPMENT

Do not open any valves or break any connections. The

standard 23XL machine is shipped with a full refriger-

ant charge. Some machines may be shipped with a

nitrogen holding charge as an option.

1. Inspect for shipping damage while the machine is still on

shipping conveyance. If the machine appears to be dam-

aged or has been torn loose from its anchorage, have it

examined by transportation inspectors before removal. For-

ward claim papers directly to the transportation com-

pany. The manufacturer is not responsible for any dam-

age incurred in transit.

2. Check all items against shipping list. Immediately notify

the nearest Carrier representative if any item is missing.

3. To prevent loss or damage, leave all parts in original pack-

ages until installation. All openings are closed with

covers or plugs to prevent dirt and debris from entering

during shipping. The 23XL is shipped with a full oper-

ating oil charge.

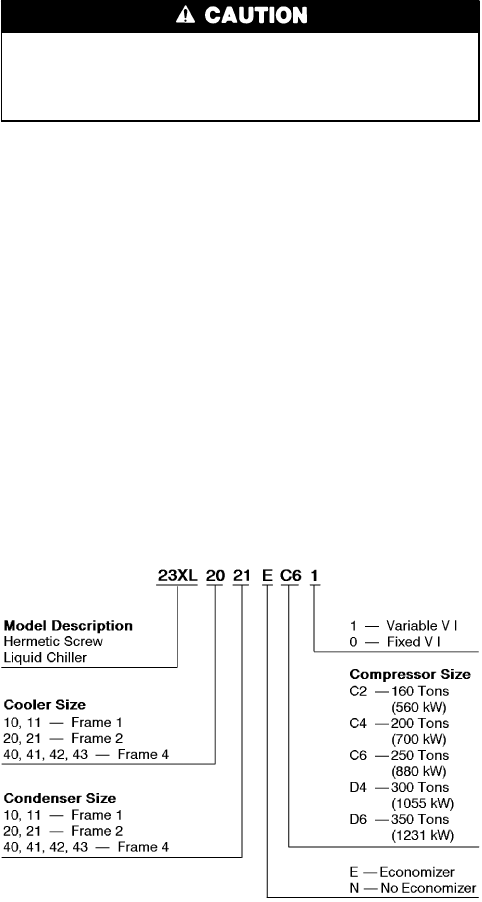

IDENTIFY MACHINE — The machine model number, se-

rial number, and heat exchanger sizes are stamped on ma-

chine information plate (Fig. 1, 2, and 3). Check this infor-

mation against shipping papers and job data.

PROVIDE MACHINE PROTECTION — Protect machine

and starter from construction dirt and moisture. Keep pro-

tective shipping covers in place until machine is ready for

installation.

If machine is exposed to freezing temperatures after water

circuits have been installed, open waterbox drains and re-

move all water from cooler and condenser. Leave drains open

until system is filled.

LEGEND

VI — Volumetric Index

Fig. 1 — Model Number Identification

2