The compressor is heavy. To avoid bodily injury, lift

the compressor only by using cables or slings. Do not

lift the compressorusing threaded eyebolts.Metric threaded

eyebolts are provided only for lifting individual com-

pressor castings.

IMPORTANT: Only a qualified service technician

should disassemble and reassemble the machine.After

reassembly, the machine must be dehydrated and leak

tested.

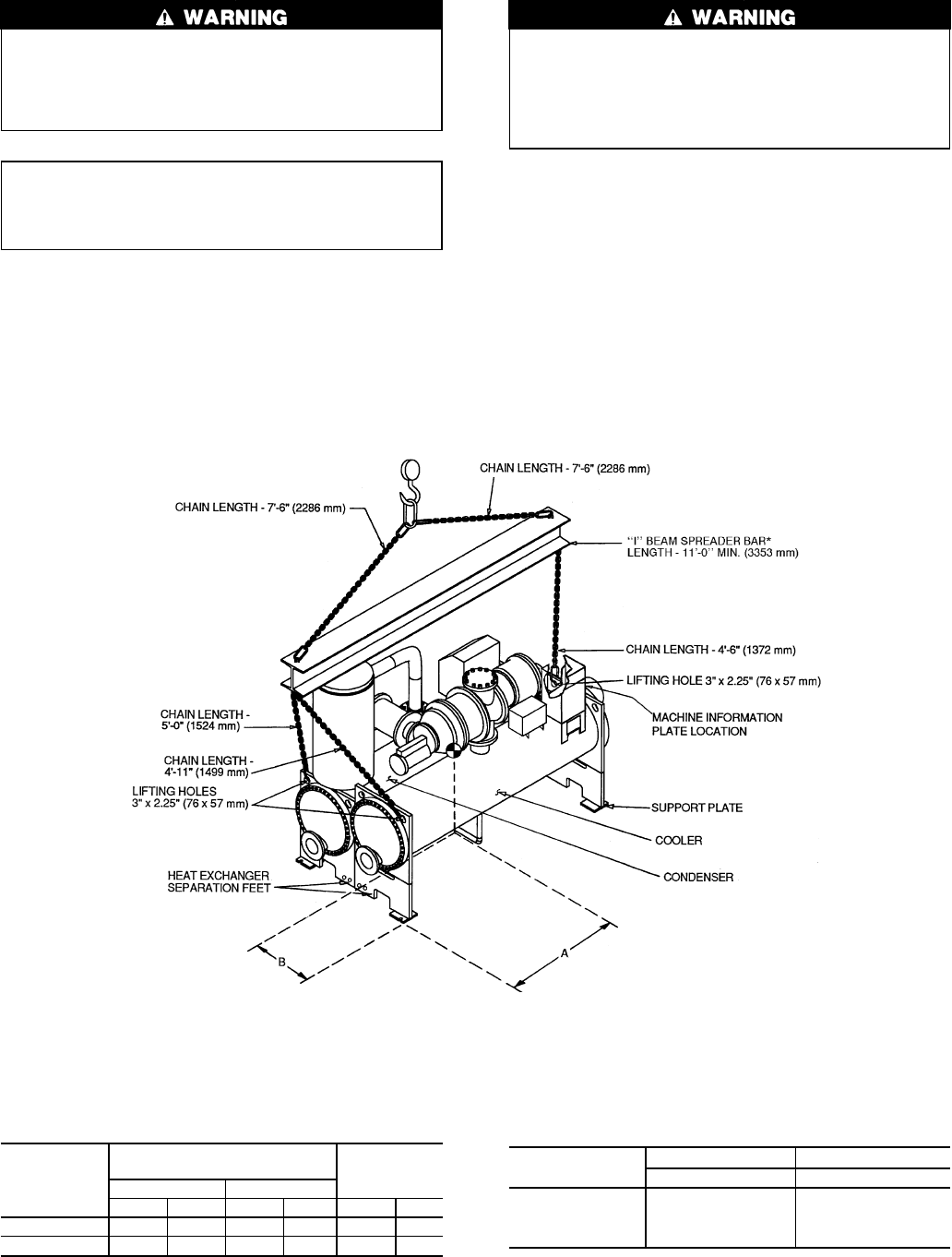

RIG MACHINE COMPONENTS — Refer to instructions

below, Fig. 8-12, and Carrier certified prints for machine

disassembly.

Do not attempt to cut refrigeration lines or disconnect

flanges or fittings while machine is under pressure. Cut-

ting lines or disconnecting flanges or fittings can result

in personal injury or damage to the unit. Be sure both

refrigerant and oil charge are removed from the ma-

chine before separating the components.

NOTE: If the cooler and condenser vessels must be sepa-

rated, the heat exchanger separation feet must be unbolted,

rotated, and rebolted in order to keep each heat exchanger

level. See Fig. 4, 5, and 8-12.

NOTE: Sensor wiring must be disconnected. Label each wire

before removal (see Carrier certified prints). Remove all trans-

ducer and thermistor wires at the sensor. Clip all wire ties

necessary to remove the wires from the heat ex-

changers. Remove the control wiring and oil heater wiring

(Frame 1 and 2 machines) at the power panel and the main

motor leads at the starter lugs before disconnecting the starter

from the machine.

*Carrier recommends that ‘‘I’’ Beam Spreader Bars be field supplied and installed.

NOTES:

1. Each chain must be capable of supporting the entire weight of the machine. Maxi-

mum weight of machine is 13,200 lbs (5940 Kg).

2. Chain lengths shown are typical for 15 ft (4572 mm) lifting height. Some minor

adjustment may be required.

HEAT

EXCHANGER

SIZE

CENTER OF GRAVITY —

APPROXIMATE DIMENSIONS

MAXIMUM

WEIGHT

A (Length) B (Width)

ft-in. mm ft-in. mm lb Kg

10 or 11 3- 8 1117 1-11 572 11,810 5357

20 or 21 3-10 1161 2- 0 600 13,200 5940

Suggested ‘‘I’’ Beam Spreader Bar*

OPTIONS

ENGLISH SI

in. x lb/ft cm x N/m

1 S12 x 31.8 S30 x 464

2 S10 x 35 S25.4 x 511

3 W12 x 22 W30 x 321

4 W10 x 25 W25.4 x 365

Fig. 4 — Machine Rigging Guide (Frame 1 and 2 Machines)

5 796

→