Operator’s Manual P/N-260AOZ-A

______________________________________________________________________________

3

Installation

CORRECT INSTALLATION

You have purchased the finest Steam Cooking Equipment

made. The following information we know will increase the

productivity and life span of the equipment.

Every product needs proper installation and with a

steamer it is critical. The following is some important

information you should check on before and during

installation of the equipment.

Water

The quality of water you put into the steam generator is

important. Poor quality water will create generator prob-

lems.

Water is no longer just plain and simple water has many

natural ingredients in it. These are called Total Dissolved

Solids, or TDS. This includes calcium, iron, and other

minerals in the water that collect in the steam generator

Because of the droughts in many areas, water and TDS's

are being pumped up from the bottom of the water

systems. If these TDS are not pre-filtered out or cleaned

out with a regular preventive maintenance program, your

steam generator could deteriorate and develop holes.

CHLORIDE is another chemical in our water creating

many problems with all steam generators. When the gen-

erator creates steam from the water it also carries the

chloride gas with it. These chlorides begin to eat away the

inside of the generator and follow the steam into the

compartments causing a rusting action (oxidation) as it

goes along.

A CARBON OR CHARCOAL FILTER must be installed on

the incoming water line to the steamer if the chlorine is

over 30 parts per million. These filters will remove the

chloride.

The WATER QUALITY REQUIREMENTS for your

STEAMER are as follows:

Total Dissolved Solids less than 60 parts per million

Total Alkalinity less than 20 parts per million

Silica less than 13 parts per million

Chloride less than 30 parts per million

pH Factor greater than 7.5

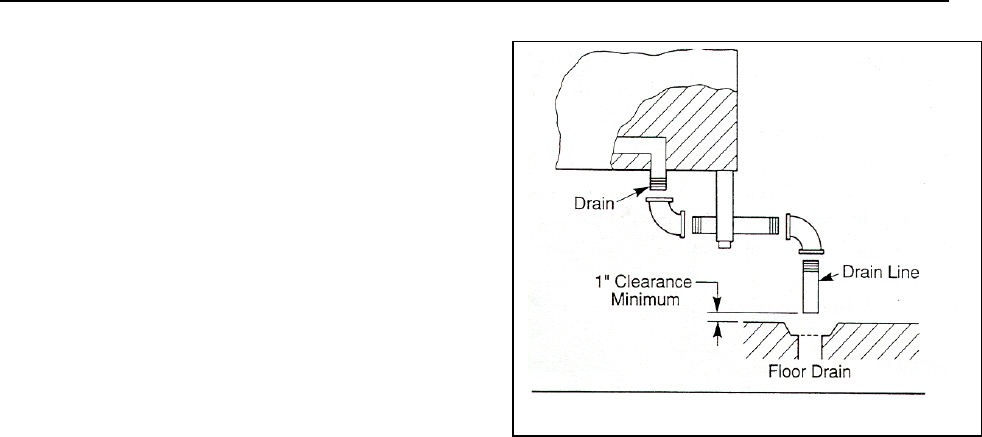

Drain Line Connection

A proper drain line connection is important. If the drain line

is clogged it can create a back up of pressure causing

extreme and costly repairs.

Figure 1. Drain Connections

If the drain line is not large enough, not open at the end, or

does not have a gravity flow; pressure and hot water will

back up into the compartments. If any of these conditions

exist and hot water does back up into the compartment

someone could be seriously burned and injured. This can

happen even with a correct installation if a drain cleaner is

not used on a regular basis.

An open and free flowing drain line IS REQUIRED for the

proper cooking performance of a CONVECTION

STEAMER. It helps create a swirling action around the

products being cooked. This movement of hot steam

around the product is your CONVECTION STEAM

COOKING.

DO NOT INSTALL UNIT OVER A FLOOR DRAIN. If it

becomes an absolute must, using an 18.' stainless steel or

aluminum pan turn it over and cut a notch in the side wall

to fit over the drain line. Place the pan directly over the

drain opening- DO NOT SEAL TO THE FLOOR. The

steam from the drain line will collect on the under side and

condense into the drain opening.

DO NOT INSTALL GAS UNITS ON

FLAMMABLEFLOORS OR NEAR WALLS. A flammable

floor or wall is any material such as wood, linoleum, or

vinyl that is easily ignitable and bums rapidly.

The intent of these instructions is to provide meaningful

information, which will help you obtain many years of

production. Before installing the steamer, please read

those instructions carefully to maintain your safety and

warranty