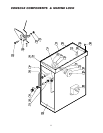

3. Remove Guard Bracket (A).

4. Pull Pressure Relief Valve (B) open to insure vessel

is not pressurized.

5. Remove Pressure Relief Valve (B).

6.

Replace Pressure Relief Valve (B) with Street Elbow (C).

7. Add distilled water (D) through the Street Elbow (C),

using a funnel if necessary. Refer to

Distilled Water

Requirements

chart for the proper amount required.

8. Apply a thread sealant (i.e. Teflon tape) to the

Pressure Relief Valve's (B) thread and replace.

9. Replace Guard Bracket (A).

10.

Restore power to unit at the fused disconnect switch.

11.

The kettle must now be vented. (Refer to the Kettle

Venting Instructions shown below).

A. Remove

Guard

Bracket

B.

*

Remove

Pressure

Relief

Valve

C.

Attach Street

Elbow

D. Fill unit via Street Elbow

*Important-

Pull ring on Pressure Relief Valve

prior to removal to insure vessel is not pressurized.

Pressure Relief Valve/Gauge Assembly Drawing

KETTLE VENTING INSTRUCTIONS

RESERVOIR FILL

PROCEDURES

The kettle's water level must be maintained at the proper level to

submerge the heater elements. Under normal operating

conditions, the sealed water reservoir should never require the

addition of water.

If the red "low water" light comes on during use (while the kettle is

in an upright position), the water level has reached a critically low

level. The low water protection control has automatically shut off

the heater elements. The following procedure must be completed

before further use:

NOTE: Have a qualified service technician repair the leakage

problem and add water to the unit. Ensure that the red "low water"

light is on when the kettle is upright. On tilting kettles, it is normal

for the red light to come on when the kettle is in a tilted position, as

the elements are not submerged in water at this point.

CAUTION: Only a mixture of distilled water and rust inhibitor should

be used when adding water to a partially filled water reservoir. Local

tap water conditions may cause kettle damage which is not covered

under warranty. Rust inhibitor is purchased locally. Read directions

and do not exceed manufacturer's recommendation (excessive rust

inhibitor can also cause solidification).

DISTILLED WATER REQUIREMENTS

1. Ensure kettle is at room

temperature and pressure

gauge showing zero or less

pressure.

2. Shut off power to the kettle at

the fused disconnect switch.

When Red “Low Water When the Reservoir is

Kettle Light” comes Completely Empty,

Capacity on, add Distilled Water Add Distilled Water

3 gallon 50 ounces 120 ounces

6 gallon 70 ounces 160 ounces

12 gallon 120 ounces 2 gallon

20 gallon 1 gallon 3 gallon

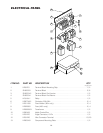

1. Remove guard bracket from

pressure relief valve/gauge

assembly.

2. Turn kettle ON and set

Temperature Control to 10

(Max.), heat the empty kettle

until unit cycles off.

3. Vent kettle by pulling safety

valve ring 8-10 times in short

2-3 second blasts with a 5

second interval between

pulls.

NOTE: If unit cycles ON, stop

venting and wait for kettle to

cycle OFF before continuing.

4. Turn kettle OFF. Add cold

water to kettle until its surface

temperature is below 100°F.

The pressure gauge needle

should be in the green zone,

indicating a vacuum in the

kettle’s jacket.

5. Replace guard bracket from

pressure relief valve/gauge

assembly.

2

3

5

6

7

8

9

1

4

10

OFF

50

0

100

150

200

250

300

350

400

40

50

60

0

10

20

30

psi

kPa

V

E

N

T

A

I

R

50

0

100

150

200

250

300

350

400

40

50

60

0

10

20

30

psi

kPa

V

E

N

T

A

I

R

50

0

100

150

200

250

300

350

400

40

50

60

0

10

20

30

psi

kPa

V

E

N

T

A

I

R

18

Guard

Bracket

Pressure

Gauge

Pressure

Relief

Valve

The following venting procedure

should be followed when the

Vacuum/Pressure Gauge needle

is in the "VENT AIR" zone:

NOTE: Check for and eliminate leaks prior to venting

(See Repairing Leaks in Steam Jacketed Kettle Fittings

on page 19).