24G SERIES FLATBOTTOM GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1-15

1.7.6 Replacing the Frypot

Unit should be at room temperature, disconnected from gas and electrical service, and empty of oil

or shortening prior to beginning procedure.

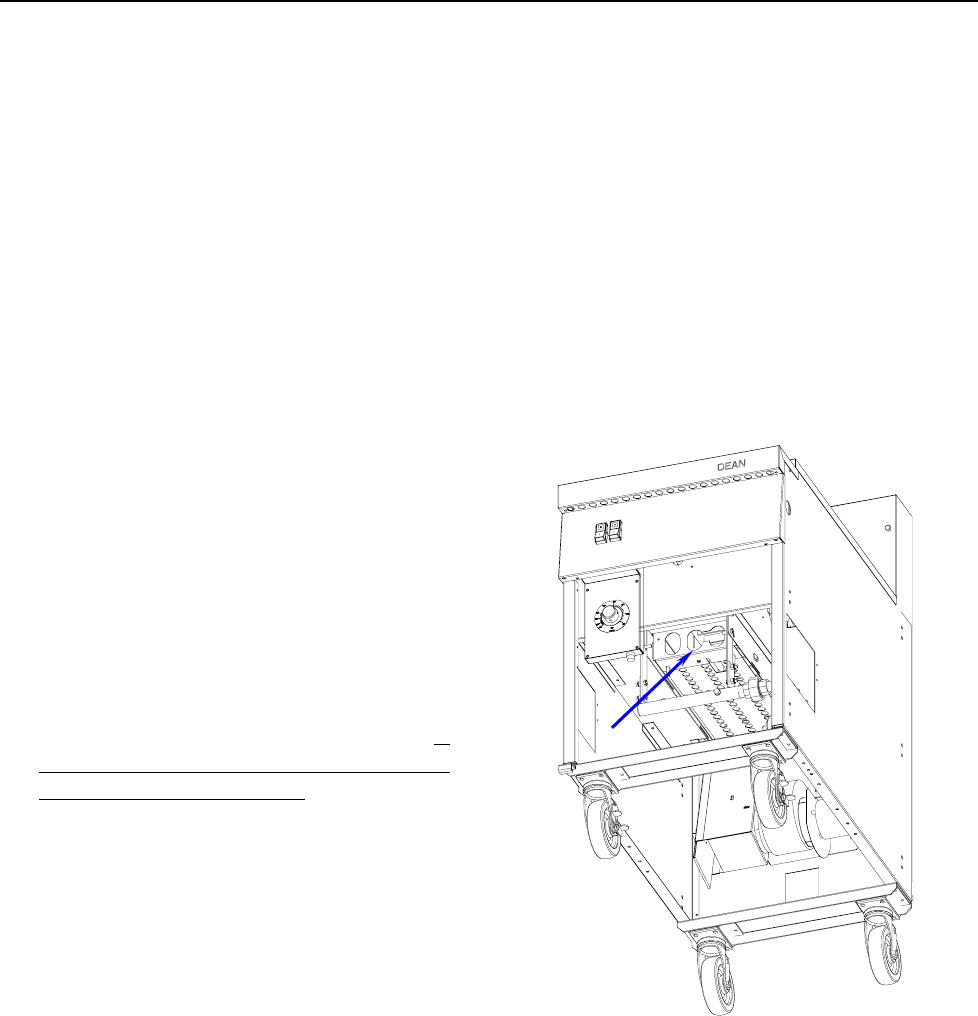

1.7.6.1 Frypot Baffle Inspection

1. Remove cabinet door(s) by holding door and lifting up on hinge pin. Current production model

doors have spring-loaded pins that must be disengaged from the control panel and the bottom

hinge. Remove marine edge (if applicable) by lifting up and off topcap and set aside.

2. The burner-tube retainer strip and burner tubes must be removed from the frypot/firebox being

inspected. Remove the burner-tube shield and the burner-tube retainer from the burner-box and

set aside. Lift the burner tubes up over each orifice and then pull outward to remove.

3. Disconnect the pilot gas-supply tube and

remove the pilot assembly (without

electronic ignition), or disconnect the

sense wire and ignition cable and remove

the direct-spark ignitor assembly (with

electronic ignition). Inspect frypot baffles

for signs of burn-through or damage. If

baffle burn-through or damage is visible,

proceed to the next section. If not, and no

further service to frypot/firebox is

required, reverse the above steps to

reassemble the fryer.

Inspect frypot baffles through burner tube opening

(arrow) for signs of burn-through or damage.