24G SERIES FLATBOTTOM GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1-1

1.1 Functional Description

24G Series Flatbottom gas fryers contain a welded steel frypot (mild steel) with heat-transfer ducting

on the frypot bottom for efficient heating of oil without scorching. A draft inducer draws air over

the burners for combustion. Air movement directs the combustion products back and forth across

the frypot bottom by means of a set of baffles, transferring the heat evenly. Cold air is prevented

from entering the combustion chamber and cooling the oil during the coasting cycle.

Flames originate from orifices in three tubular burners positioned at the front and beneath the frypot.

The diameter of the orifices differs for Natural (CE:G20/G25) and LP (CE:G31) gas as indicated in

the table below.

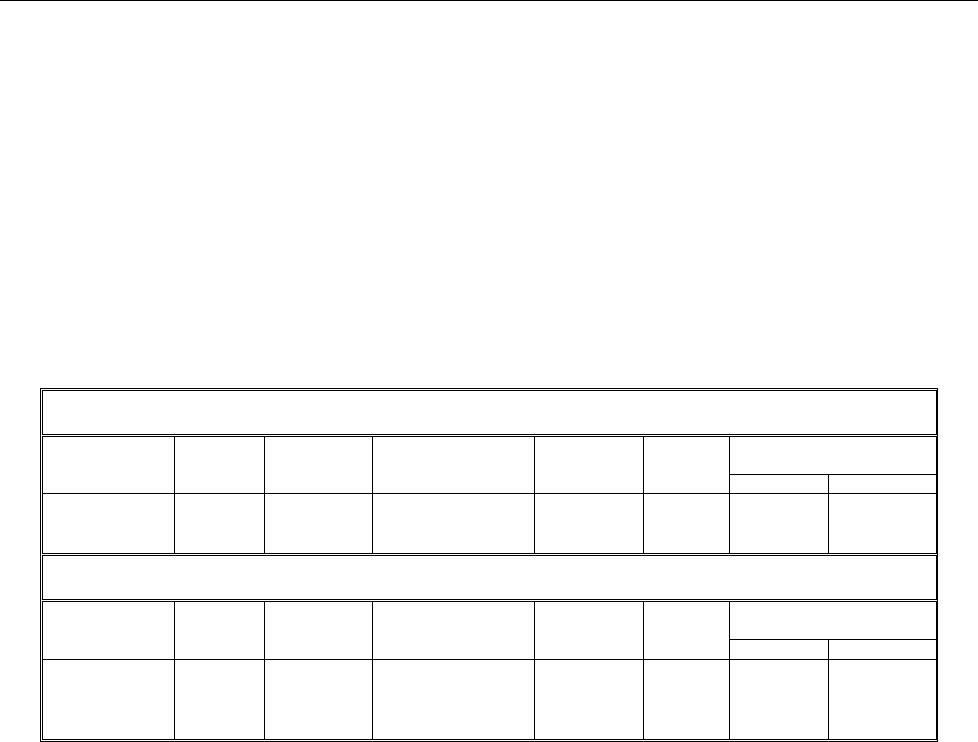

NON-CE (Altitudes of 2000 feet or less)

EQUIPMENT

PRESSURE

MODEL

INPUT

(BTU)

GAS TYPE

ORIFICE

[DRILL SIZE (MM)]

ORIFICE

PART #

QTY

MBAR INCH W.C.

1824/2424G 120

NAT

LP

#34 (2.82)

#50 (1.78)

810-2051

810-2317

3

3

10

27.5

4

11

CE ONLY (Altitudes of 2000 feet or less)

EQUIPMENT

PRESSURE

MODEL

INPUT

(kW)

GAS TYPE

ORIFICE

(MM)

ORIFICE

PART #

QTY

MBAR INCH W.C.

1824/2424G

30,0

(88,000

BTU)

G20

G25

G31

2,50

2,50

1,60

810-2628

810-2628

810-2317

3

3

3

14,5

21,0

31,0

5,8

8,4

12,44