PrecisionSwirl Overview

310554V 9

PrecisionSwirl Overview

PrecisionSwirl Capabilities

The PrecisionSwirl orbital dispenser is regulated

through the control assembly. The orbital dispenser is

used to swirl sealant and adhesives in a variety of appli-

cations.

In a basic robotic system, the control assembly serves

as the interface between the robot controller and the

orbital dispenser via an interface cable. Refer to Robot

Interface Cable Assembly on page 52.

The orbital dispenser is operated either manually from

the control assembly or automatically from a robot con-

troller where the orbital dispenser is programmed to

apply material continuously, or at interrupted intervals,

or both. The orbital dispenser can be stopped, started,

and regulated to suit the application, making high quality

swirl patterns that hold form after the material is dis-

pensed.

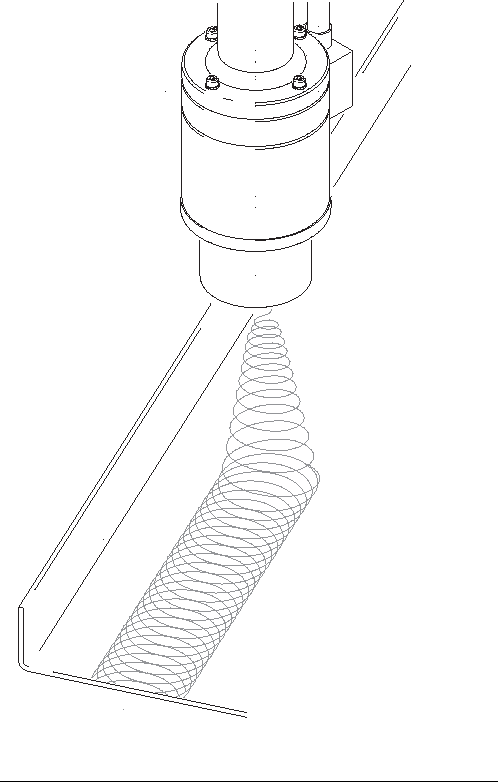

The orbital dispenser applies a continuous swirled bead

of material directly on components in targeted areas,

such as the hem flanges on car doors, the interior

seams of the chassis, and on the fixed glass openings of

autos.

Bead profile is “pre–shaped” in a uniform pattern of

overlaid circular loops (see F

IG. 2). Bead shape is

affected by nozzle size, material composition, flow rate,

stand off distance, and orbital dispenser motor speed.

The oscillating nozzle on the orbital dispenser can apply

an accurate swirled bead of material on vertical and hor-

izontal planes.

The orbital dispenser is small enough to apply sealant

and adhesives on any type of surface or material, and

can be directed on any programmable path, including: a

series of crevices, creases, or around a maze of straight

lines, sharp angles, contours, curves, corners, and

openings.

The material source for the orbital dispenser is com-

monly supplied via a dual ram pump fluid supply system,

which can be equipped with filters, temperature condi-

tioning, and a fluid supply header.

F

IG. 2

8128B