Miscellaneous Machine Setups

312393G 19 of 50

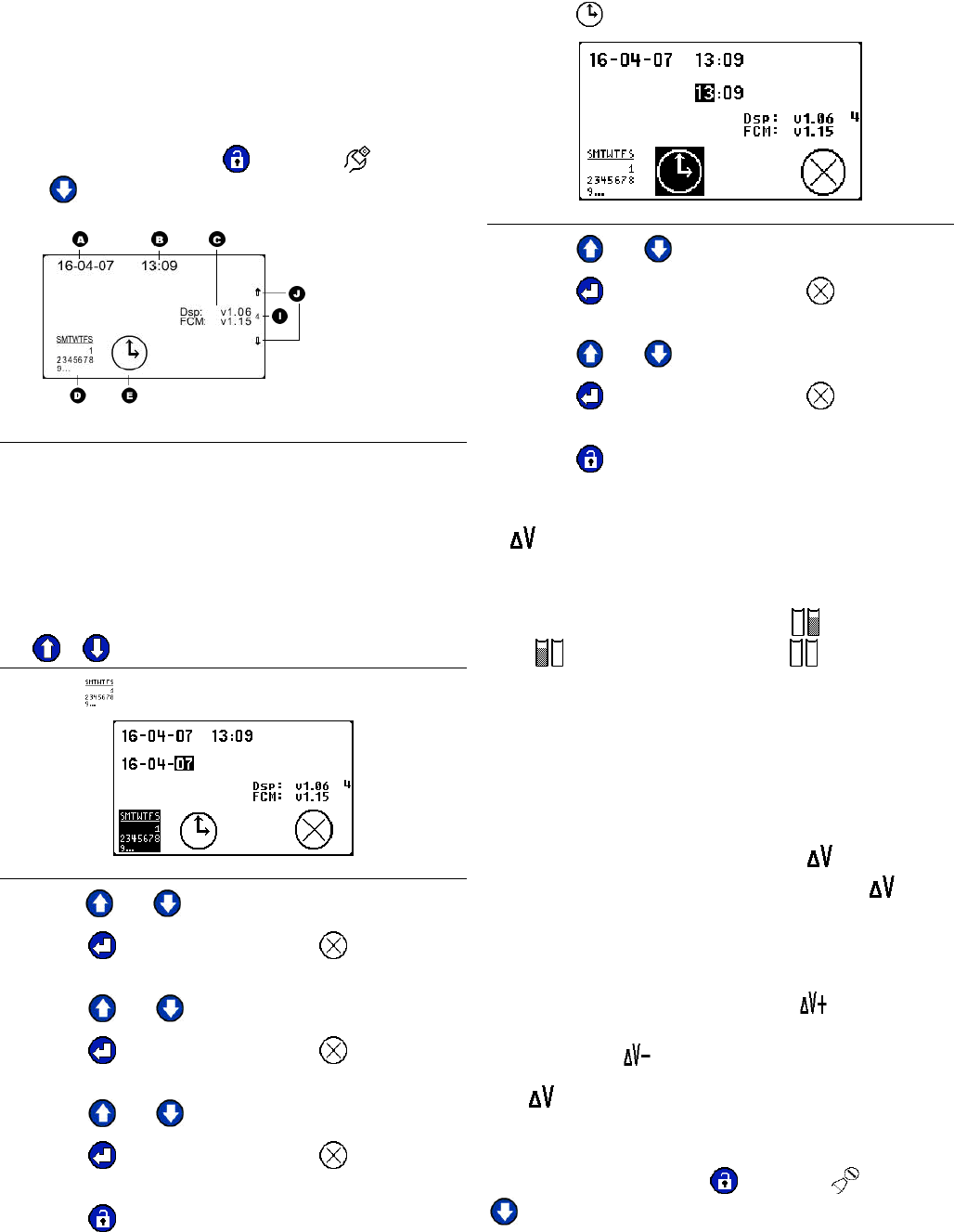

Date and Time Settings (M4)

At the bottom right corner of the Run screen the date is

shown in DD-MM-YY format and the time is shown in

HH:MM, 24 hour format. The formats cannot be changed.

To set the current date:

From the Run screen, press

, then press , and then

press

3 times. The following screen will be displayed.

Figure 23: M4 Screen for Setting the Date and Time

Key:

A Current Date (DD-MM-YY)

B Current Time (HH:MM, 24 Hour Format)

C Current Software Revision

Dsp = Display Module

FCM = Fluid Control Module

D Date Set ICON

E Time Set ICON.

I Screen Number (M4)

J

& keys will navigate to adjacent screens.

1. Press . The M4 screen will appear as follows.

Figure 24: M4 Screen after Date Set Selection

3. Press and to enter the year.

4. Press

to accept the change or to retain the

previous setting.

5. Press and to enter the month.

6. Press

to accept the change or to retain the

previous setting.

7. Press and to enter the day.

8. Press

to accept the change or to retain the

previous setting.

9. Press

twice to return to the Run screen.

To set the current time:

1. Press

. The M4 screen will appear as follows.

Figure 25: M4 after Time Set Selection

2. Press and to enter the hour (0 - 23).

3. Press

to accept the change or to retain the

previous setting.

4. Press

and to enter the minutes (0 - 59).

5. Press

to accept the change or to retain the

previous setting.

6. Press

twice to return to the Run screen.

Tank Level Sensing and Velocity Change

(“ ”) Options (C6)

If tank level sensors are installed into the system, an

alarm is generated when a tank is almost empty. If the

feature is turned ON, a Tank A low (“

”), a Tank B

low (“

”), or a both tanks are low (“ ”) error will be

generated if the condition exists.

The machine also measures the piston velocity and

will generate an alarm if the piston velocity has

changed significantly since the machine was last

calibrated. A significant change is piston velocity,

usually caused by a change in air pressure, can

degrade shot size accuracy.

The user has the capability to turn the

feature OFF

by selecting a level of 0%, or ON by selecting

levels

of 20%, 40% or 60%. For instance, if 40% is selected,

and the piston velocity changes by + or – 40%, an error

code will be generated after the corresponding shot to

inform the operator of the situation. If the velocity

increases above the selected level, a

error will be

generated, and if the velocity decreases below the

selected level a

error will be generated.

The

feature is automatically disabled when the

machine is in Operator mode, or when the machine is

executing a purge shot.

From the Run screen, press

, then press , then press

5 times. The following screen will be displayed.