Pistons & Metering Tubes

312393G 39 of 50

To install a new Piston or Piston/Cylinder

Replacement Kit:

1. Drain the machine pistons by instigating several

shots with either the tank ball valves closed (if

installed), or by activating enough shots to empty

the tanks.

2. To prevent machine movement, press

(red).

3. Remove the pump end caps (item 8 of figure 46)

by removing the 4 end cap screws (item 6 of

figure 46). Allow the cap to hang by the hose.

4. Remove the cylinder and Orings (items 1 and 6 of

figure 50) from the pump housing (item 7 of figure

46) and pump cap.

5. Select an operating mode, then fully extend the

pistons by activating the

option in the M1

screen.

6. To prevent machine movement, press

(red).

7. Remove the existing piston (1) and any front or

rear washers (items 3 & 4 of figure 50) from the

pump shaft (item 11 of figure 46) by removing the

piston screw (2). A wrench will be required near

the drive block to prevent the pump shaft from

rotating while the screw is removed.

8. Install the new piston and any rear or front

washers, by re-installing the piston screw into the

pump shaft. When tightening the piston screw,

tighten the screw until the piston stops rotating,

then turn the screw an additional ¼ turn.

9. Select an operating mode, then retract the

pistons by pressing

in the M1 screen.

10. To prevent machine movement, press

(red).

11. Lubricate the new o-rings with a high temperature

grease, Graco P/N 115982 or equivalent. Place

the lubricated o-rings into the inside circle

placements in the pump housing and pump end

caps.

12. Install the cylinder between the pump housing

and end cap, then secure the cylinder and Orings

by re-attaching the 4 end cap screws (item 6 of

figure 46).

13. Open the tank ball valves (if installed) or put more

material into the tanks.

14. Instigate several shot to fill the pump with new

material.

15. Re-calibrate the machine, due to the procedure

performed.

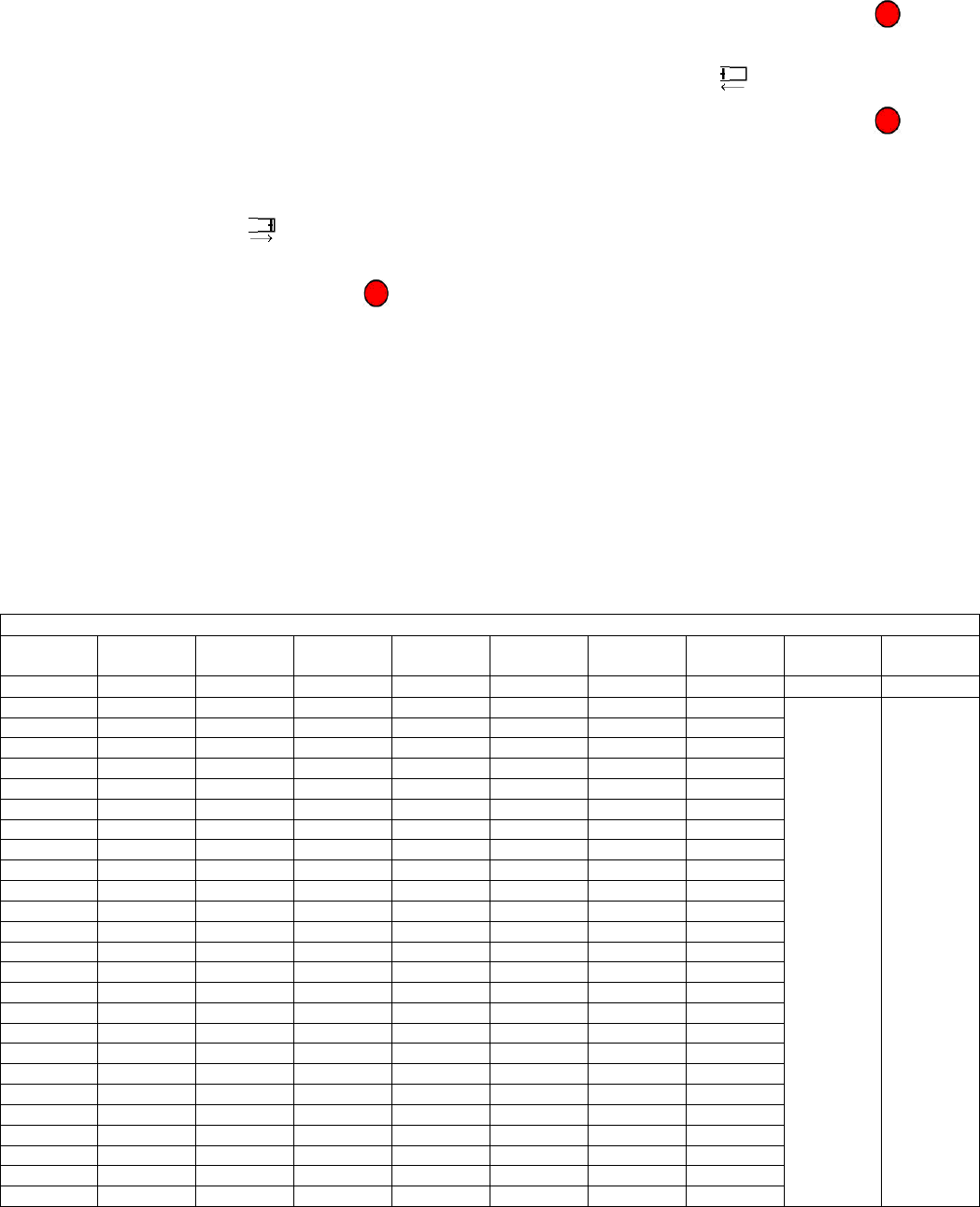

NYLON PISTONS (SEE FIGURE 50)

Tube Piston

Frt.

Washer

Back

Washer

Screw O-ring

Part No. Rev. Series Area Item 1 Item 2 Item 3 Item 4 Item 5 Item 6

LC1080 A A 80 LCC080 LCB080 15M089 NOT REQ

120933 120874

LC1100 A A 100 LCC100 LCB 100 15M089 NOT REQ

LC1120 A A 120 LCC120 LCB 120 NOT REQ NOT REQ

LC1140 A A 140 LCC 140 LCB 140 NOT REQ NOT REQ

LC1160 A A 160 LCC 160 LCB 160 15M099 15K887

LC1180 A A 180 LCC 180 LCB 180 15M099 15K887

LC1200 A A 200 LCC 200 LCB 200 15M099 15K887

LC1220 A A 220 LCC 220 LCB 220 15M099 15K887

LC1240 A A 240 LCC 240 LCB 240 15M100 15K887

LC1260 A A 260 LCC 260 LCB 260 15M100 15K887

LC1280 A A 280 LCC 280 LCB 280 15M100 15K887

LC1300 A A 300 LCC 300 LCB 300 15M100 15K887

LC1320 A A 320 LCC 320 LCB 320 15M100 15K888

LC1360 A A 360 LCC 360 LCB 360 15M100 15K888

LC1400 A A 400 LCC 400 LCB 400 15M100 15K888

LC1440 A A 440 LCC 440 LCB 440 15M100 15K888

LC1480 A A 480 LCC 480 LCB 480 15M100 15K888

LC1520 A A 520 LCC 520 LCB 520 15M100 15K888

LC1560 A A 560 LCC 560 LCB 560 15M101 15K888

LC1600 A A 600 LCC 600 LCB 600 15M101 15K888

LC1640 A A 640 LCC 640 LCB 640 15M101 15K890

LC1720 A A 720 LCC 720 LCB 720 15M101 15K890

LC1800 A A 800 LCC 800 LCB 800 15M101 15K890

LC1880 A A 880 LCC 880 LCB 880 15M101 15K890

LC1960 A A 960 LCC 960 LCB 960 15M101 15K890