Troubleshooting

312393G 29 of 50

Troubleshooting

Before starting any troubleshooting procedures:

1. Relieve pressure (refer to Pressure Relief

Procedure Section).

2. Disconnect AC power to the machine.

3. Allow the machine to cool, if the machine has a heat

control option.

Try the recommended solutions in the order given for

the each problem to avoid unnecessary repairs. Also

verify all circuit breakers, switches, and controls are

properly set and wiring is correct before assuming there

is a problem.

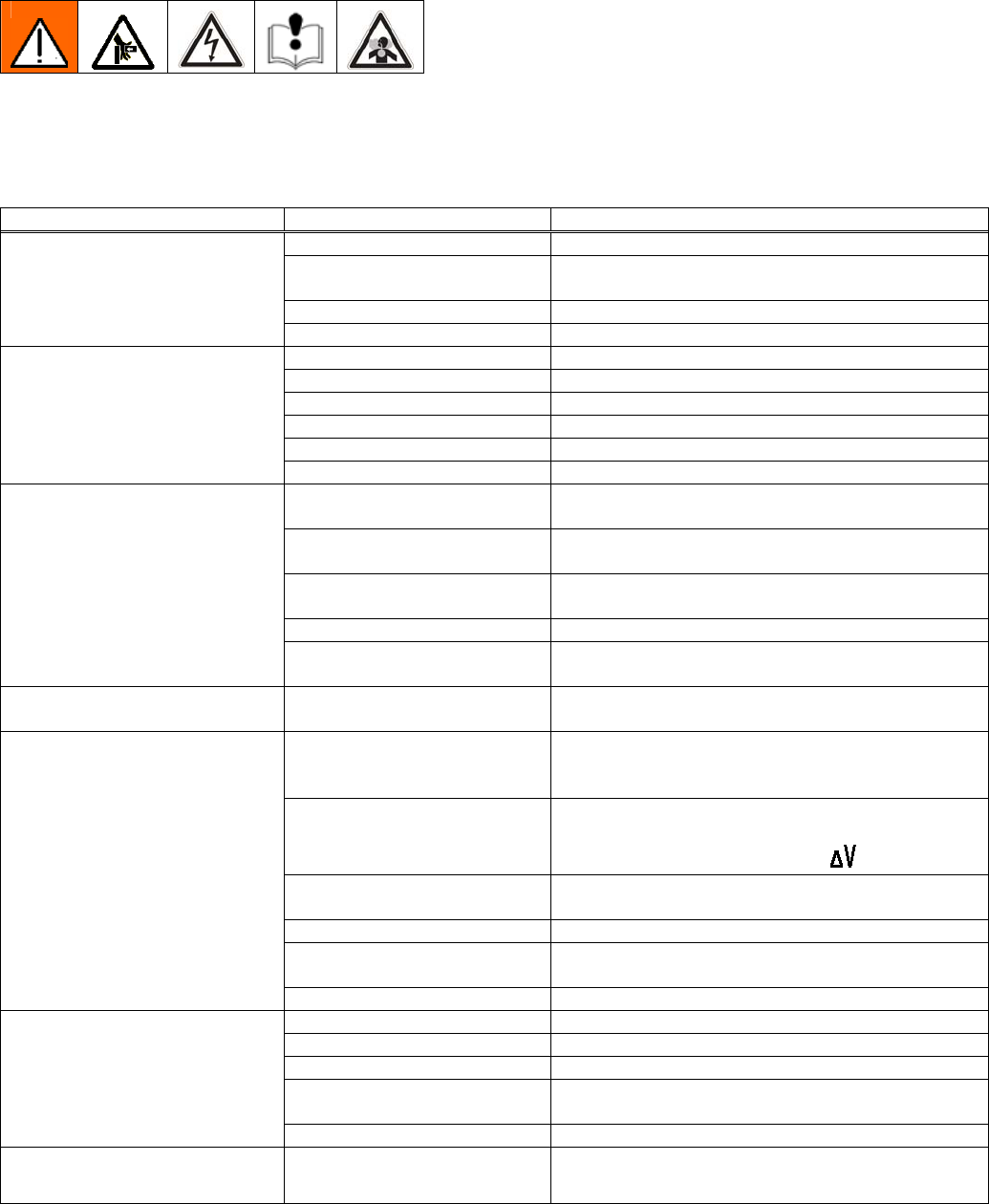

PROBLEM CAUSE SOLUTION

HMI Display Completely Dark

No Power Verify rear AC Power switch is ON.

Fuse Blown Replace Machine fuses (Refer to “Miscellaneous

Mechanical Assemblies” Section).

Loose connection Tighten 5 pin cable on HMI.

Bad HMI Replace HMI

No or incorrect amount of

material dispensed from either

side

Ball Valve Closed Open Tank Ball Valve (if installed).

Tank empty Fill tank with material

Tank Clogged Verify no obstruction in the tank

Air in material Prime the machine until the air is removed.

Check valve malfunction Remove, clean or replace check valve.

Piston worn or broken Remove and replace piston if worn.

Piston stalled (E21 Error)

Input Air Reduced or

removed

Re-connect input air line to machine. Increase

air pressure regulator adjustment.

Mixer blocked Replace static mixer. Incorporate or decrease

purge time amount to prevent mixer blockage.

ODV adjustment too late Re-adjust the ODV setting to occur sooner (C3

screen section).

Blocked Check valve Remove check valve, clean and replace.

Air Cylinder Failure Remove air cylinder and re-install cylinder kit

items if necessary.

Significant material leaking

from pump rear seal

Pump Shaft worn Remove pump shaft assembly, and re-install rear

pump re-built kit.

Material dispensed not correct

weight

Specific gravity of 1 or more

of the 2 materials has

changed since calibration.

Mix materials in tanks, dispense another shot,

then re-weigh. Re-calibrate if necessary (C4

section).

Machine Air pressure has

changed since calibration.

Re-adjust air pressure regulator to value used

when machine was calibrated, or re-calibrate (C4

section). Turn ON or decrease

% level.

Not enough material in 1 or

more tanks

Check tank levels, and fill and prime if

necessary.

Mixer has slight obstruction Replace static mixer. Re-prime machine.

Check valve malfunction Remove check valve(s), clean or replace if

necessary.

Piston worn or broken Remove and replace piston(s) if necessary.

Machine dispensing off ratio

One tank is empty Check tank levels. Add material if necessary.

Tank Ball valve Closed Open tank ball valve. Re-prime machine.

Machine out of phase Re-phase machine (C2 section).

Check valve malfunction Remove check valve(s), clean or replace if

necessary.

Piston worn or broken Remove and replace piston(s) if necessary.

Pumps drawing material back

from valve hose

Check valve stuck open Remove check valve(s), clean or replace if

necessary.