Error Code Table

312393G 24 of 50

Error Code Table

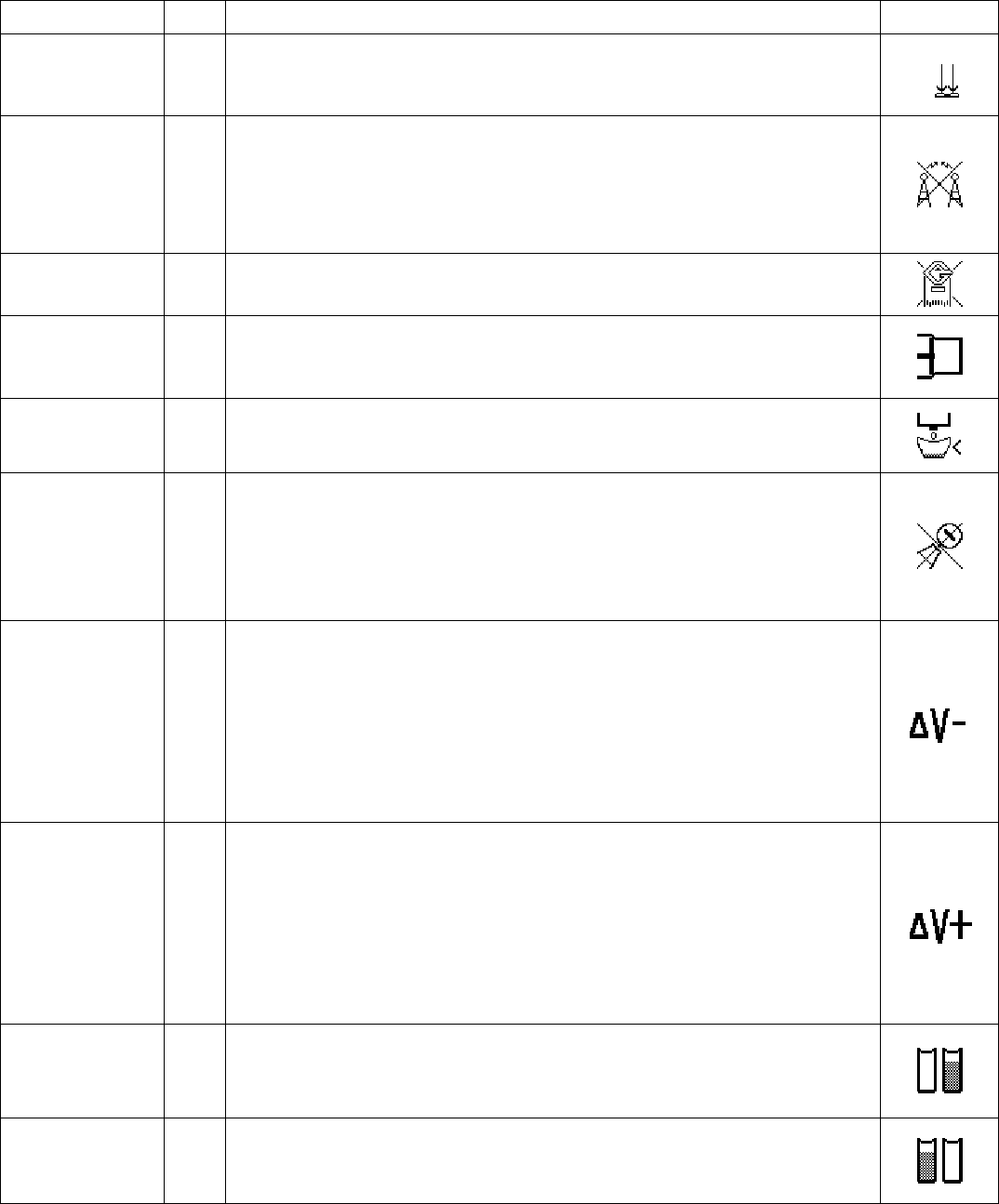

Title # Cause, Details ICON

Stuck Key Error

E11

A key on membrane has been active (pressed) for > 30 seconds continuously.

Replace the HMI. This error code does not require user acknowledgment and

will clear itself automatically if the condition is removed.

Communication

Error

E12 The Display module has lost communication with the Fluid Control Module.

Material dispensing will be disabled if this condition exists. Check

communication cables between the 2 electronic components, or check the

HMI and/or the Fluid Control Module.

This error will be regenerated continuously while the condition exists.

No or Invalid Run

Token Error

E13 The Run Token in the FCM is missing (not installed), or does not have the

correct data.

Piston Stroke

Time-out Error

E21 A piston stroke action has taken > 55 seconds. Typically caused by no/too

little air pressure to the machine or a mechanical interference with the piston

has occurred. Check machine input line pressure.

Less than

Minimum Shot

Requested Error

E23 User has requested a shot < the minimum allowable size entered during

calibration. (< 15% of stoke, N/A in Operator Mode).

Improper

Calibration Error

E24 The calibration done on the machine is invalid, so the requested shot cannot

be executed. For instance, a Large Stroke Calibration Shot mass which is

less than the Short Stroke Calibration Shot mass (C4 screen) will create this

error code. If the wiring to the linear position transducer is reversed this error

will appear. If invalid piston positions are calibrated into the machine (C1

screen) this error will appear.

Delta Velocity

(“V”) Minus Error

E25 The piston velocity is slower than the calibration velocity measured, by the

percentage amount selected by the user (20%, 40% or 60%). If the user

selects 0%, this monitoring or alarm feature is disabled.

If generated, shot size accuracy may be degraded. Typically the problem is

created when the machine pressure regulator is adjusted to different value

from when the machine was calibrated. Another less likely cause could be a

mechanical failure with dispensing (worn piston, etc.). This error will not be

generated for a purge shot or when the machine is in Operator mode.

Delta Velocity

(“V”) Plus Error

E26 The piston velocity is faster than the calibration velocity measured, by the

percentage amount selected by the user (20%, 40% or 60%). If the user

selects 0%, this monitoring or alarm feature is disabled.

If generated, shot size accuracy may be degraded. Typically the problem is

created when the machine pressure regulator is adjusted to different value

from when the machine was calibrated. Another less likely cause could be a

mechanical failure with dispensing (worn piston, etc.). This error will not be

generated for a purge shot, or when the machine is in Operator mode.

Low Material

Level, Tank A

Alarm or Error

E27 Tank A is low (only generated if tank sensing is enabled). Fill tank A with

material.

Tank level errors will be generated after every shot if the condition still exists.

Low Material

Level, Tank B

Alarm or Error

E28 Tank B is low (only generated if tank sensing is enabled). Fill tank B with

material.

Tank level errors will be generated after every shot if the condition still exists.