– 15 –

OWNER PREVENTIVE MAINTENANCE PROCEDURE

INTRODUCTION

This customer preventive maintenance (PM) section includes procedures to inspect for proper

operation and cleaning of components. Owner Preventive Maintenance Procedures are written for gas

ovens. They can also be used for electric ovens by omitting the steps that refer to components found

only on gas ovens. Customer PMs should be conducted bi-monthly per OSHA Bakery Oven Inspection

Standard 29 CFR 1910.263(l)(9)(ii). A convenient PM Checklist is provided at the end of this section.

NOTE: This PM procedure does not discuss repair or replacement of components. Upon completion

of the PM procedure you will need to contact a qualified servicer for any needed repairs.

Tools Used For Inspection Procedure

• Standard set of hand tools

• Vacuum cleaner - shop vac

PREVENTIVE MAINTENANCE PROCEDURE

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE AND FOLLOW

LOCKOUT/TAGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE SERVICING THE UNIT.

WARNING: CERTAIN PROCEDURES IN THIS SECTION REQUIRE ELECTRICAL TEST OR

MEASUREMENTS WHILE POWER IS APPLIED TO THE MACHINE. EXERCISE EXTREME

CAUTION AT ALL TIMES. IF TEST POINTS ARE NOT EASILY ACCESSIBLE, DISCONNECT

POWER AND FOLLOW LOCKOUT / TAGOUT PROCEDURES, ATTACH TEST EQUIPMENT AND

REAPPLY POWER TO TEST.

Inspect Oven Lamps

1. Lamps should be on when oven is powered.

2. If not, replace lamps.

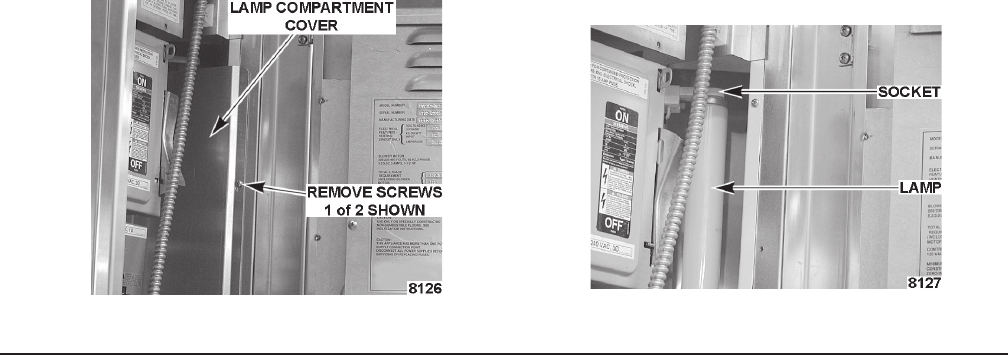

A. Remove screws securing lamp compartment cover (Fig. 1) and pull cover towards you to

disengage cover from rear tabs.

3. Twist lamp (Fig. 2) to disengage from lamp sockets (Fig. 2) and carefully withdraw lamp from

area.

4. Reverse procedure to install new lamps.

Fig. 1

Fig. 2