– 5 –

INSTALLATION

Generally, installations are made by the dealer or

contracted by the dealer or owner. Detailed installation

instructions are included in the Installation & Operation

Manual which is sent with each unit.

OPERATION

Detailed operation instructions are included with each

oven.

CLEANING

Detailed cleaning procedures are included in the

Installation & Operation Manual for the appropriate

model.

LUBRICATION

Motor bearings are sealed and prelubricated.

SPECIFICATIONS

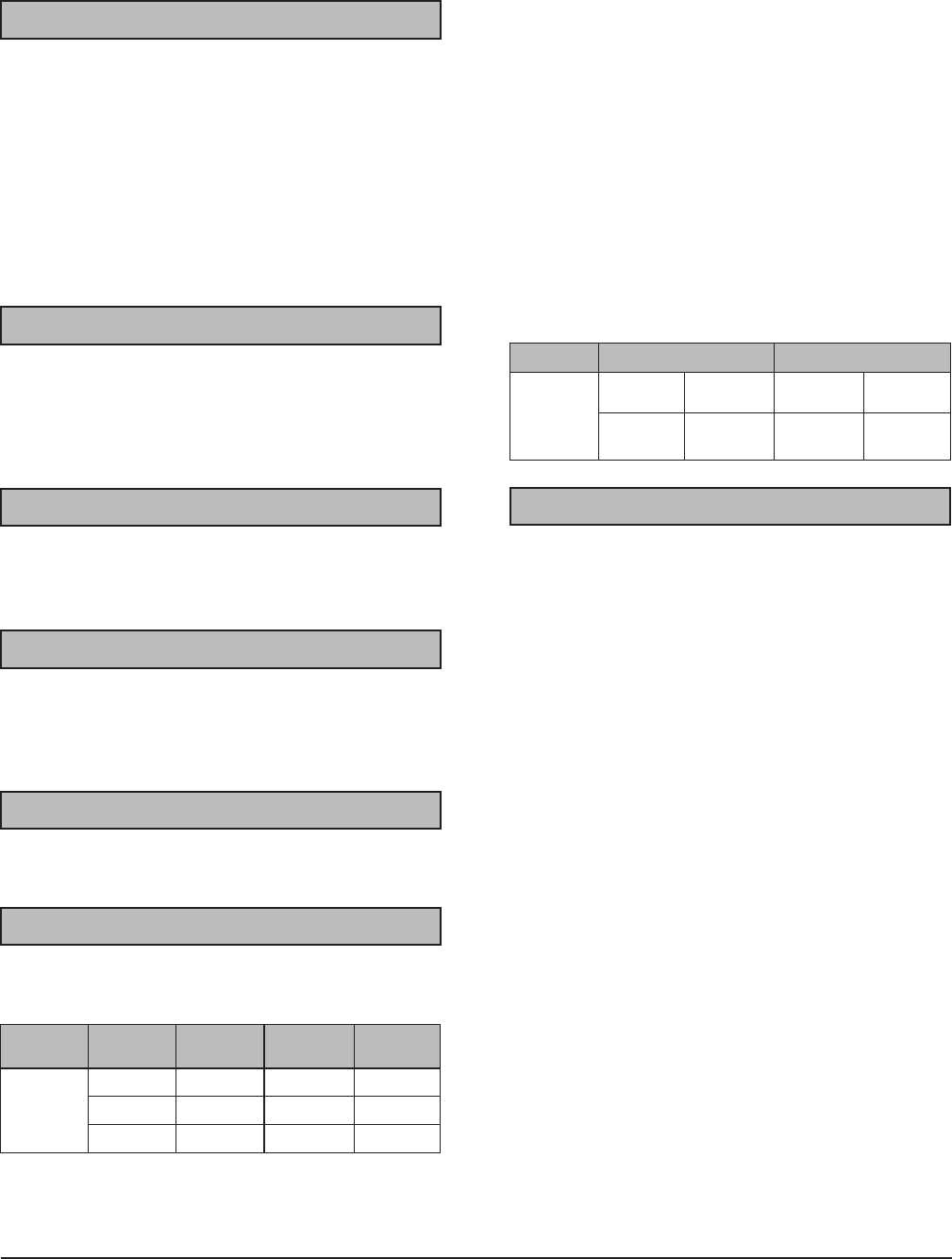

Electrical Data

INTRODUCTION

GENERAL

Gas Data

TOOLS

Standard

• Hand tools (standard set).

• VOM with AC current tester (any quality VOM

with a sensitivity of at least 20,000 ohms per

volt can be used).

• Gear puller to remove blower.

Special

• Temperature tester (thermocouple type).

• Manometer

Procedures in this manual will apply to all models unless specified. Pictures and illustrations can be of any model

unless the picture or illustration needs to be model specific. All models are equipped with a two-speed

1

/2 HP electric

motor, porcelain interior and two 30,000 BTU/hr burners as standard equipment. A power level control permits

variable burner input from 15,0000 BTU/hr to 60,000 BTU/hr.

Models SG4D and SG6D are equipped with solid state-controls and a 60-minute timer (a 5-hour timer is optional).

Models SG4C and SG6C have a computer control with built-in Roast & Hold.

Models SG6D and SG6C have a 4" deeper cavity than models SG4D and SG4C.

ledoM stloV ztreH esahP spmA

D4GS

C4GS

D6GS

C6GS

0210615.7

8020616.3

04206157.3

ledoM tupnIUTBrh/ erusserPdlofinaM

,D4GS

,C4GS

,D6GS

C6GS

larutaNsaGPLlarutaNsaGPL

000,06000,06

.C.W"5.3

)aPk9.0(

.C.W"01

)aPk2.2(