2-4

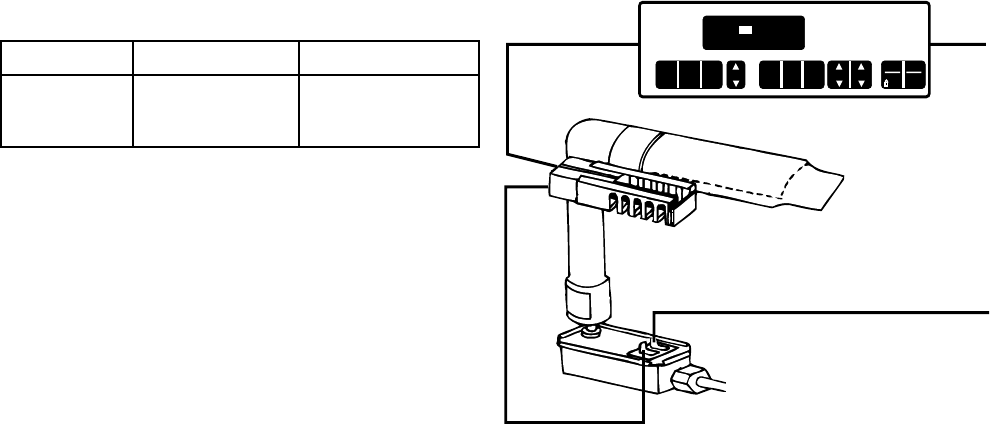

TROUBLESHOOTING THE IGNITOR SYSTEM

PROGRAM DIAGRAM A DIAGRAM B

Bake P3-1 to P2-1 P2-3 to P2-4

Broil P3-1 to P2-1 P2-2 to P2-1

Diagram A—Bake:

With the EOC programmed

for the Bake mode, you should obtain a read-

ing of 120 VAC between P3-1 and P2-4, and

between P3-4 and P2-1.

Diagram A—Broil:

With the EOC programmed

for the Broil mode, you should obtain a read-

ing of 120 VAC between P3-2 and P2-1, and

between P3-1 and P2-2.

Diagram B—Bake:

With the EOC programmed

for the Bake mode, you should obtain a read-

ing of 120 VAC between P2-4 and Neutral.

L1

N

ELECTRONC OVEN CONTROL

IGNITOR

BURNER

DUAL GAS

SAFETY VALVE

BAKE

HR MIN

CUSTOM

BROIL

AUTO

CLEAN

CLOCK

TIME

DELAY

TIMER

SET

STOP

TIMER

OFF

OFF

CANCEL

START

ENTER

5 SEC

HEAT BAKE BROIL LOCKED CLEAN TIMER

O

F

ON

350

10:30

AB

C

D

Ignitor Glows With No Ignition

1. Check that gas is turned on to the range.

2. Turn the power on and set the thermostat

to 350˚F.

3. Check the ampere draw at the bimetal

valve.

a) Using a wraparound ammeter, test one

leg for ampere draw at "D" or "C".

1. NORTON (flat) Ignitor - 3.2 to 3.6

amps.

2. CARBORUNDUM (round) Ignitor-

2.5 to 3.0 amps.

If the ampere draw is NOT within the

proper range, replace the ignitor.

b) If the correct ampere draw is present,

replace the valve.

For safety purposes, when measuring the

current flow through the ignitor circuit, shut

off the main, or the oven gas shut-off valve.

NOTE: A simple circuit is shown. The actual

circuit may include fuses, clock, selector

switch, or other items.

Diagram B—Broil:

With the EOC programmed

for the Broil mode, you should obtain a read-

ing of 120 VAC between P2-1 and Neutral.

Refer to the illustration below while you read

the following troubleshooting information.

Ignitor Does Not Glow

1. Disconnect or remove the ignitor and mea-

sure its resistance. Cold resistance should

be between 50 and 150 Ohms. (The value

of the resistance is not important as long

as the ignitor is not open or shorted).

2. Check the internal fuses, switches, and

120 VAC power supply.

3. If power is working:

a) Disconnect the oven power and re-

move wires at “B” and “C”.

1. Check continuity between wire “B”

and terminal “C”. If continuity is

present, go to Step 4.

b) If continuity is NOT present, remove

wire at “D” and probe terminals “D”

and “C” for continuity. If NO continu-

ity, replace the bimetal valve.

c) If continuity is present at “D” and “C”,

probe wires “B” and “D”. If NO continu-

ity, replace the ignitor.

4. Check for

120 VAC

at the following loca-

tions, and the relay(s) on the Electronic

Oven Control you are servicing. Also re-

fer to the wiring diagrams on the next

page.