Introduction

2

Oven Description and Specifications

Cooking i n a conveyor oven differs from cooking

in a conventional deck or range oven since heated

air is constantly recirculated over the product by

a fan in an enclosed chamber. Themoving air con -

tinually strips aw ay the layer of cool air s urround -

ing the product, quickly allowing the heat to pene-

trate. The result is a high quality product, cooked

at a lower temperature in a shorter amount of time.

Blodgett conveyor ovens represent the latest ad -

vancement in energy efficiency, reliability, and

ease of operation. Heat normally lost, is recircu -

lated within the cooking chamber before being

vented from the oven: resulting in substantial re-

ductions in energy consumption, a cooler kitchen

environment and enhanced oven performance.

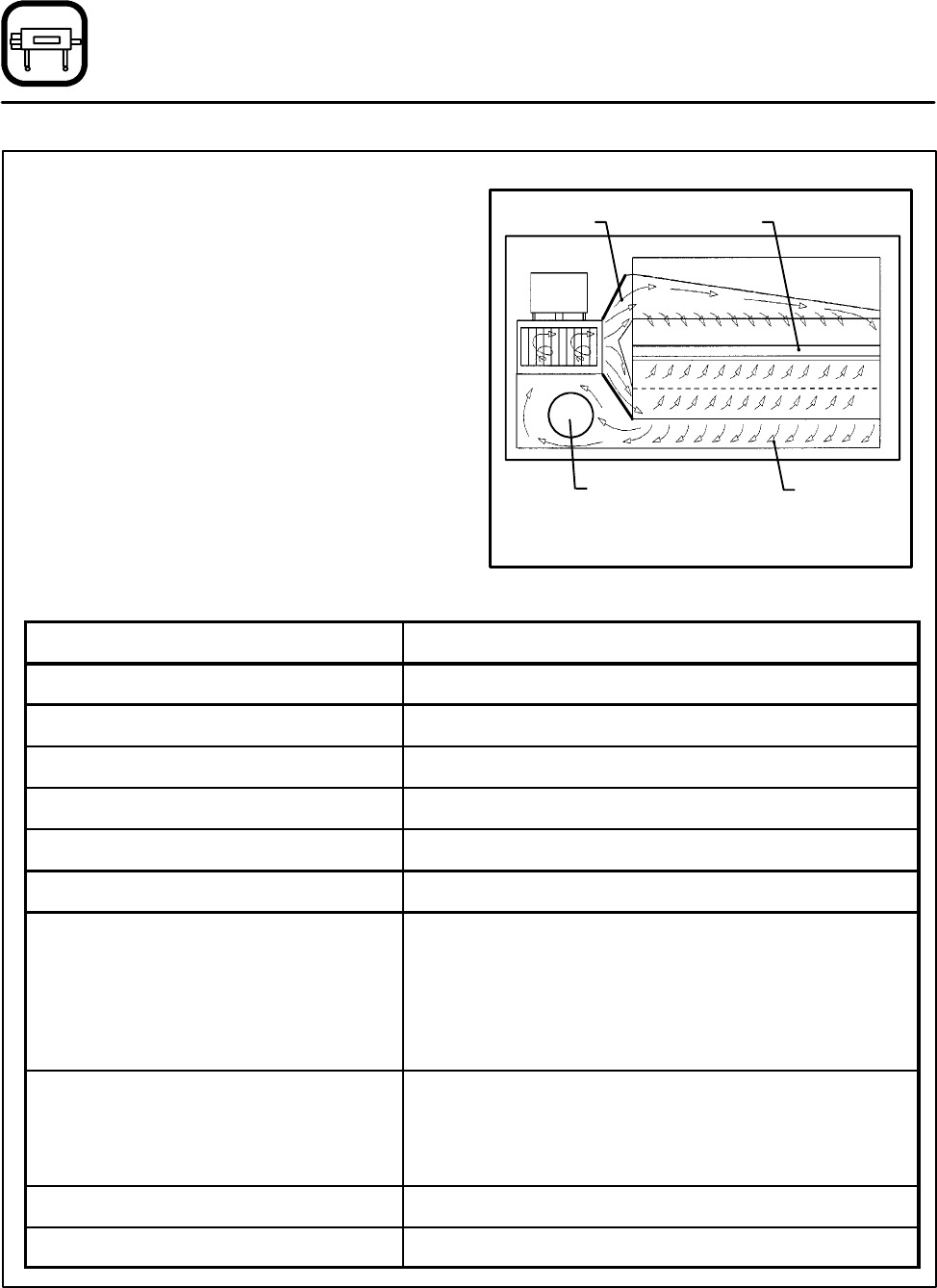

AirFlowPatternforBlodgettConveyorOvens

Heated Air Conveyor

Combustion

Chamber

Return Air

Figure 1

SPECIFICATIONS

MT3855G -G

Belt Width 38” (96.5 cm)

Cooking Zone Length 55” (139.7 cm)

Baking Area 14.5 Sq. Ft. (1.3 m

2

)

Dimensions (single unit) 91” x 58” x 44” (231 cm x 147 cm x 112 cm)

Maximum Input 150,000 BTU /Hr. (43.9 kW) (158 MJ)

Maximum Operating Temperature 600_F (315_C)

Power Supply U.S. and Canadian installations:

120/208-240VAC, 60Hz., 1Φ,9Amp,

3 wire with g round

Australia and General Export installations:

220-240VAC, 50Hz., 1Φ,9Amp,

3 wire with g round

Gas Supply Natural Gas: 4.5” W.C. (1.1 kPa) minimum

10.5” W.C. (2.61 kPa) maximum

Propane: 11.0” W.C. (2.74 kPa) minimum

13.0” W.C. (3.2 kPa) ma ximum

Product Clearance 3.0” (7.6 cm)

Gas Supply Connection 3/4” (1.9 cm)