2-7

When using thread compound, use very small amounts on male threads only. Use a pipe thread

compound that is not affected by the chemical action of LP gases (Loctite™ PST56765 Sealant

is one such compound). DO NOT apply compound to the first two threads. This will ensure that

the burner orifices and control valve do not become clogged.

2. Open the gas supply to the fryer and check all piping, fittings, and gas connections for leaks. A

soap solution should be used for this purpose.

DANGER

Never use matches, candles, or any other ignition source to check for leaks. If gas

odors are detected, shut off the gas supply to the fryer at the main shut-off valve and

contact the local gas company or an authorized service agency for service.

3. Close the fryer drain valve and fill the frypot with water and boil-out solution to the bottom OIL

LEVEL line at the rear of the frypot. Light the fryer and perform the boil-out procedures that are

described in the “Lighting Instructions” and “Boiling Out the Frypot” topics found in Chapter 3

of this manual.

WARNING

“Dry-firing” your unit will cause damage to the frypot. Always ensure that melted

shortening, cooking oil, or water and boil-out solution is in the frypot before firing

your unit for any extended period.

4. It is suggested that the burner manifold pressure be checked at this time by the local gas

company or an authorized service agent.

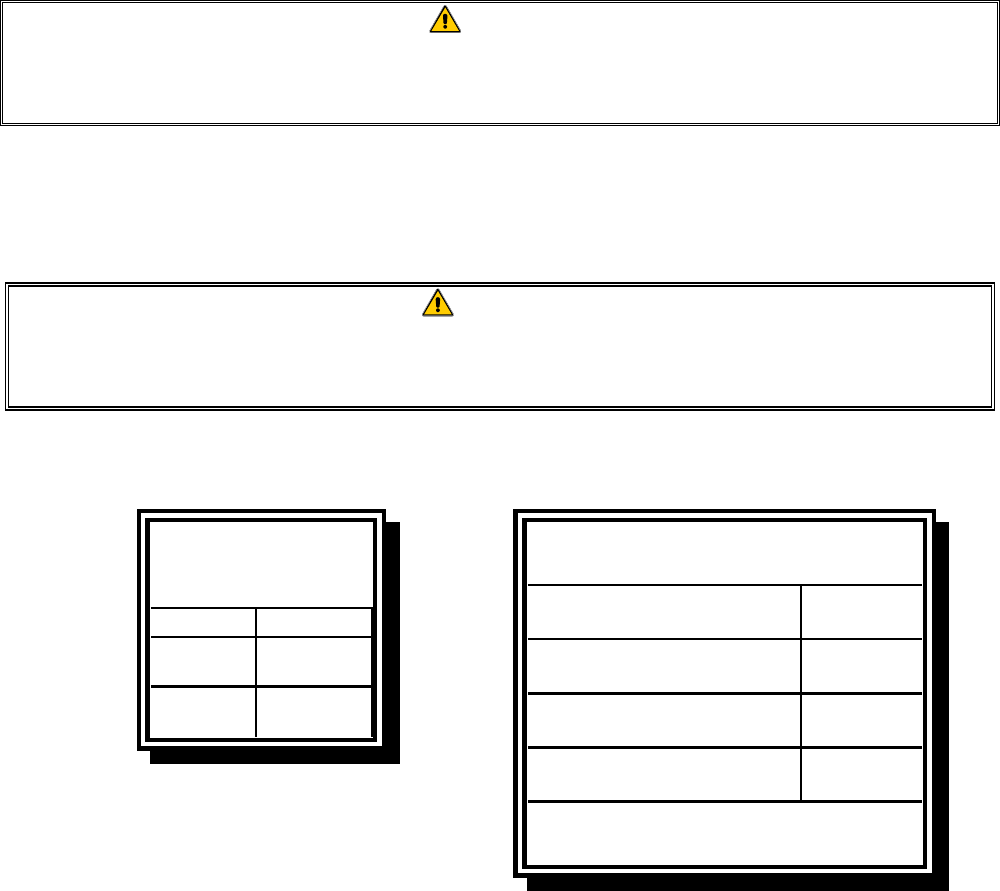

Non-CE Standard

Burner Manifold Gas

Pressures

Gas Pressure

Natural

3.5" W.C.

0.8 kPa

LP

8.25" W.C.

2.5 kPa

Gas

Pressure

(mbar)

Natural Gas Lacq

(G20) under 20 mbar

8

Natural Gas Gronique

*

(G25) under 25 mbar

10

Propane

(G31) under 37 or 50 mbar

21

CE Standard

Burner Manifold Gas Pressures

* Belgian G25 = 7,0 mbar

5. For units equipped with thermostat controls, check the thermostat calibration as prescribed in the

following section. For units equipped with other type controllers, refer to the separate Frymaster

Fryer Controllers Users Manual provided with this equipment for the procedure to be followed

to set and check the setpoint temperature.