6-5

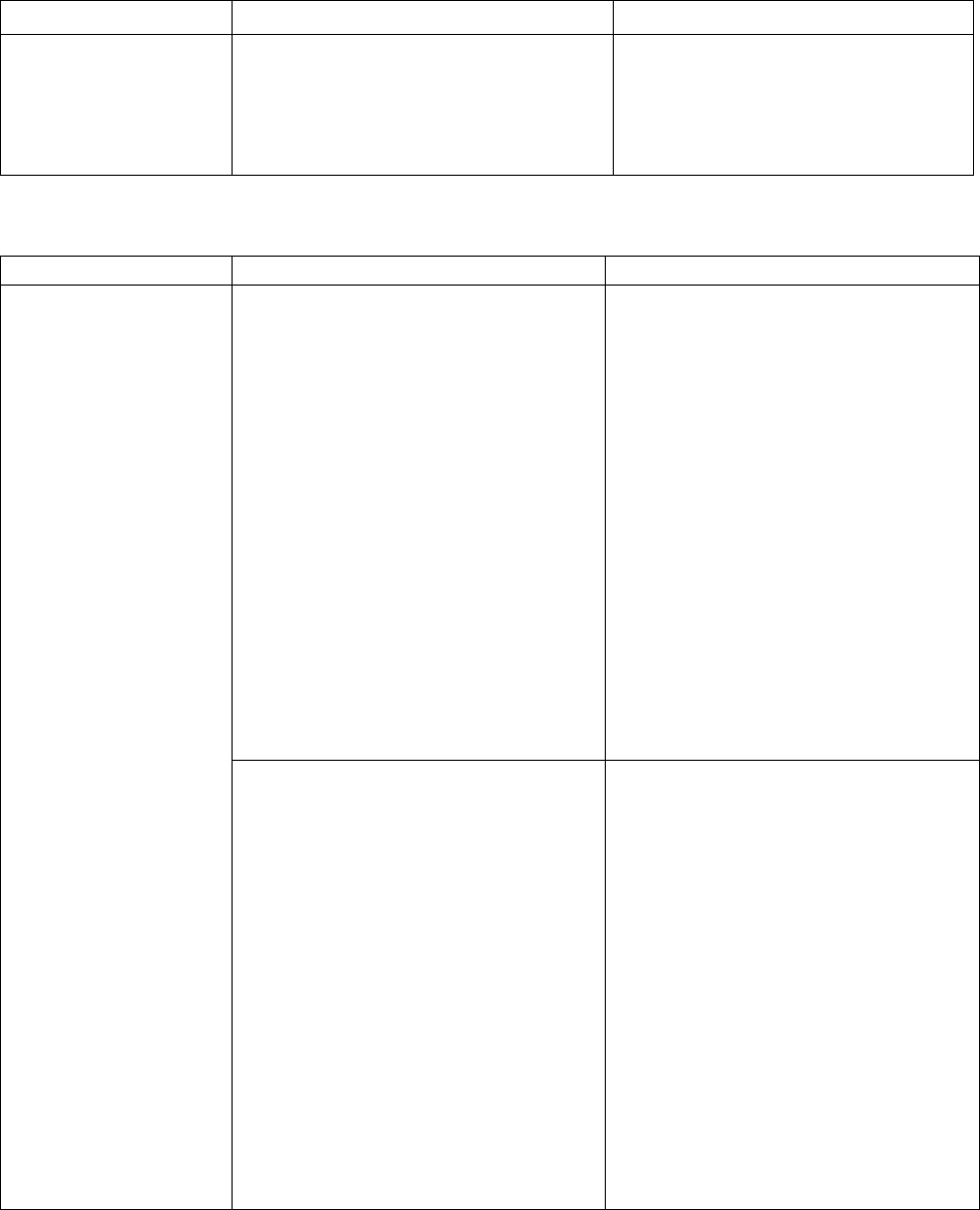

Problem Probable Causes Corrective Action

M2000 display

shows HI 2 BAD.

Computer in hi-limit test mode.

This is displayed only during a test

of the hi-limit circuit and indicates

that the hi-limit has failed. DO

NOT OPERATE THE FRYER!

Call FASC.

6.4 Troubleshooting the Built-in Filtration System

PROBLEM PROBABLE CAUSES CORRECTIVE ACTION

A. Thermal overload switch has

tripped on an overheated motor.

Test: If the pump stopped

suddenly during the filtering

process, especially if after several

filtering cycles, the pump motor

has probably overheated. Place

the filter handle in the OFF

position, allow the pump to cool

for at least 45 minutes, and then

press the reset button on the pump

motor. Attempt to activate the

pump.

A. If the pump runs normally after

resetting the thermal overload

switch, the pump was overheated.

Always filter with the cooking

oil/shortening at or near frying

temperature.

Allow the pump motor to cool off

for about ten minutes after

filtering two full frypots one after

the other.

Check the filter pad between

filtering. Replace the pad if there

is a large accumulation of

sediment.

B. Failed filter handle microswitch.

Test: If this is a multi-pot fryer,

attempt to operate the pump using

a different handle. If the pump

starts, the handle microswitch is

either out of alignment or has

failed.

When the handle is placed in the

ON position, the lever on the

microswitch should be firmly

pressed against the switch. If so,

the switch has failed. If not, the

switch is loose and/or misaligned.

B. If the switch is loose, tighten the

nuts and bolts holding it in place,

ensuring that when the handle is

placed in the ON position, the

lever on the microswitch is

pressed firmly against the switch.

If the switch has failed, call

FASC.

Pump won’t start.

OR

Pump stops during

filtering.