16 Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

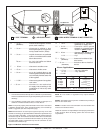

90 DEGREE

ELBOW

PIPE LENGTH

PIPE LENGTH

WALL THIMBLE

COVER

WALL THIMBLE

TERMINATION CAP

Step 1.

Determine the desired location of the gas stove. Check to

ensure that wall studs or roof rafters are not in the way when

the flue system is being planned. If this is the case, you may

want to adjust the location of the gas stove.

E. Horizontal Termination

Step 3.

For installations using a round support box/wall thimble

(check pipe manufacturer's instructions), mark the wall for

a 25.4 cm x 25.4 cm square hole. The center of the square

hole should line up with the center line of the horizontal

pipe, as shown in Figure 5.12. Cut and frame the hole in

the exterior wall where the flue will be terminated. If the wall

being penetrated is constructed of noncombustible material,

i.e. masonry block or concrete, a 17.8 cm diameter hole is

acceptable.

C

ENTER

LINE

CENTER LINE

6 in.

4 in.

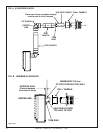

Step 2.

Balanced flue pipe is designed with a locking connection. To

connect the flue system to the gas stove flue outlet, a twist-

lock adapter is built into the gas stove at the factory. Wall

thickness may vary. Remember to include wall thickness in

minimum clearances when figuring flueing lengths for your

installation needs.

Female Locking Lugs

Male Locking Lugs

Fire Risk.

Explosion Risk.

Combustion Fume Risk.

Use fl ue run supports per installation instructions.

Connect fl ue sections per installation instructions.

• Maintain all clearances to combustibles.

• Do NOT allow fl ue to sag below connection

point to gas stove.

WARNING

Improper support may allow fl ue to sag or separate.

Fire Hazard.

Exhaust Fume Risk.

Impaired Performance of Appliance.

WARNING

• Ensure fl ue components are locked together correctly.

• Pipe may separate if not properly joined.

Step 4.

Position the horizontal termination cap in the center of the

25.4cm x 25.4cm square hole and run a bead of non-harden-

ing mastic around its outside edges, to make a seal between

it and the wall. Attach termination cap to the exterior wall

with the four wood screws provided. The arrow on the flue

cap should be pointing up.

Note: Female ends of balanced flue pipe/elbows are

designed to slide straight onto the male ends of adjacent

pipes by orienting the pipe indentations so they match and

slide into the entry slots on the male ends, see Figure 5.13.

Push the pipe sections completely together, then twist-lock

one section clockwise approximately one-quarter turn, until

the two sections are fully locked. The female locking lugs

may not be visible from the outside. They may be located by

examining the inside of the female ends.

Figure 5.13

Figure 5.12