53

B. Maintenance

The maintenance schedule below is a guideline. More frequent maintenance may be

requireddependingonwaterquality,theicemaker'senvironment,andlocalsanitation

regulations.

WARNING

•Onlyqualiedservicetechniciansshouldservicethisicemaker.

•Movethecontrolswitchandthepowerswitchtothe"OFF"positionandturnoff

the power supply before servicing. Lockout/Tagout to prevent the power supply

from being turned back on inadvertently.

Maintenance Schedule

Frequency Area Task

Every 2

Weeks

Air Filter Inspect. Wash with warm water and neutral cleaner if dirty.

Monthly External Water

Filters

Check for proper pressure and change if necessary.

Icemaker Exterior Wipe down with a clean, soft cloth. Use a damp cloth containing a neutral

cleaner to wipe off oil or dirt build up. Clean any chlorine staining (rust

colored spots) using a non-abrasive cleaner like Zud or Bon Ami.

Every 6

Months

Icemaker and

Storage Bin

Clean and sanitize per the cleaning and sanitizing instructions provided in

this manual.

Evaporator

Condensate Drain

Pan and Gear

Motor Drain Pan

Wipe down with a clean cloth and warm water. Slowly pour one cup of

sanitizing solution (prepare as outlined in the sanitizing instructions in

this manual) into the evaporator condensate drain pan. Be careful not to

overowthepan.Thissolutionwillowdowntothegearmotordrainpan

and out the drain line to sanitize these areas. Repeat with a cup of clean

water to rinse.

Icemaker, Storage

Bin, and Drip Tray

Drains

Check to make sure they are clear.

Yearly Inlet Water Valve

and Drain Valve

Close the water supply line shut-off valve and drain the water system. Clean

the inlet water valve screen and clean and inspect the drain valve.

Water Hoses Inspect the water hoses and clean/replace if necessary.

Condenser Inspect. Clean if necessary by using a brush or vacuum cleaner.

Icemaker Inspect for oil spots, loose components, fasteners, and wires.

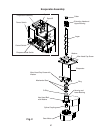

Upper Bearing

(extruding head)

Check for wear using .02" round stock or pin gauge. Replace both upper

bearing and lower bearing if wear exceeds factory recommendations. See

"V.B.1. Upper Bearing Wear Check".

After

3 Years,

then Yearly

Upper Bearing

(extruding head);

Lower Bearing

and O-Ring

(lower housing);

Mechanical

Seal; Evaporator

Cylinder; Auger

Inspect. Replace both upper bearing and lower bearing if wear exceeds

factoryrecommendations.Replacethemechanicalsealiftheseal'scontact

surfaces are worn, cracked, or scratched.