23 185211000

11. Activate the dispensing valve for one minute to purge detergent solution from and install sanitizing solution

in the product system.

12. Continue activating the dispensing valve in cycles (“ON” for 15–seconds, “OFF”, then “ON” for

15-seconds). Repeat “ON” and “OFF” cycles for 15 cycles.

13. Repeat steps 9 through 11 preceding to purge detergent solution from the remaining product systems.

14. Allow sanitizing solution to remain in the product system for not less than 10-minutes or for no more than

15-minutes.

15. Connect product tank containing potable water into the product system to be flushed.

WARNING: Flush sanitizing solution from the system(s) as instructed. Residual sanitizing

solution left in the product system(s) could create a health hazard.

16. Place waste container under applicable dispensing valve.

17. Activate the dispensing valve for one minute to purge all sanitizing solution out of the product system.

18. Continue activating the dispensing valve in cycles (“ON” for 15–seconds, “OFF”, then “ON” for

15-seconds). Repeat “ON” and “OFF” cycles for 15 cycles.

19. Repeat steps 15 through 18 preceding to purge sanitizing solution from the remaining product systems.

20. Remove product tank containing flush water from the product system, then connect a clean empty product

tank into the system.

21. Place waste container under applicable dispensing valve.

22. Activate the dispensing valve to purge all water from the product system.

23. Repeat steps 20 and 22 preceding to purge all water from the remaining product systems.

24. Dispose of waste sanitizing solution in a sanitary sewer, not in a storm drain, then thoroughly rinse the

inside and the outside of the container that was used for sanitizing solution to remove all sanitizing solution

residue.

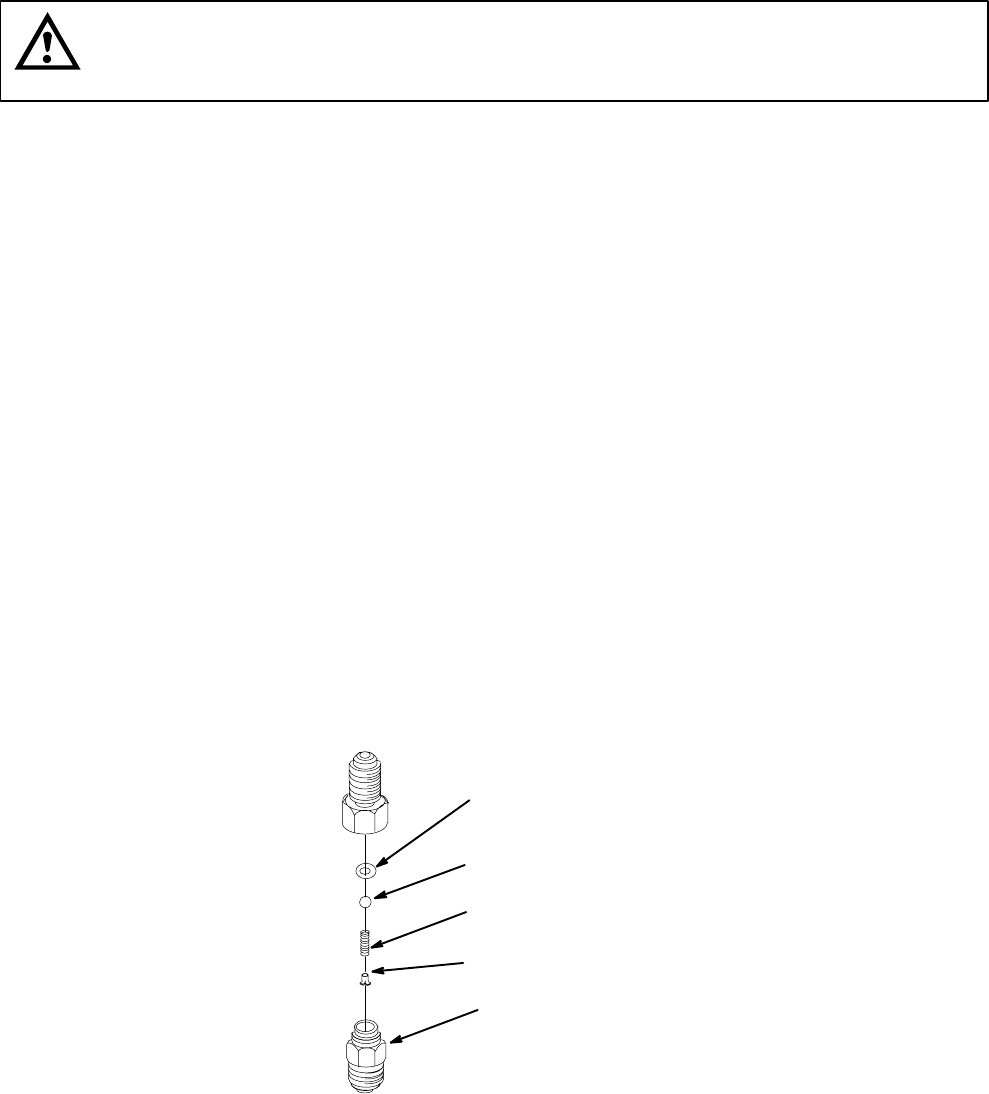

CLEANING CO

2

GAS CHECK VALVES

(see Figures 2 and 5)

The primary CO

2

regulator assembly CO

2

gas check valves must be inspected and serviced at least once a

year under normal conditions and after any servicing or disruption of the CO

2

system. ALWAYS REPLACE

QUAD RING SEAL EACH TIME GAS CHECK VALVES ARE SERVICED.

BALL

183296000

QUAD RING

183294000

SPRING

183297000

RETAINER

183298000

BODY

183295100

*Quad ring seal must be replaced

each time check valve is serviced.

FIGURE 5. CO

2

GAS CHECK VALVE