Environmental Requirements

R

30 mPGA604 Socket Design Guidelines

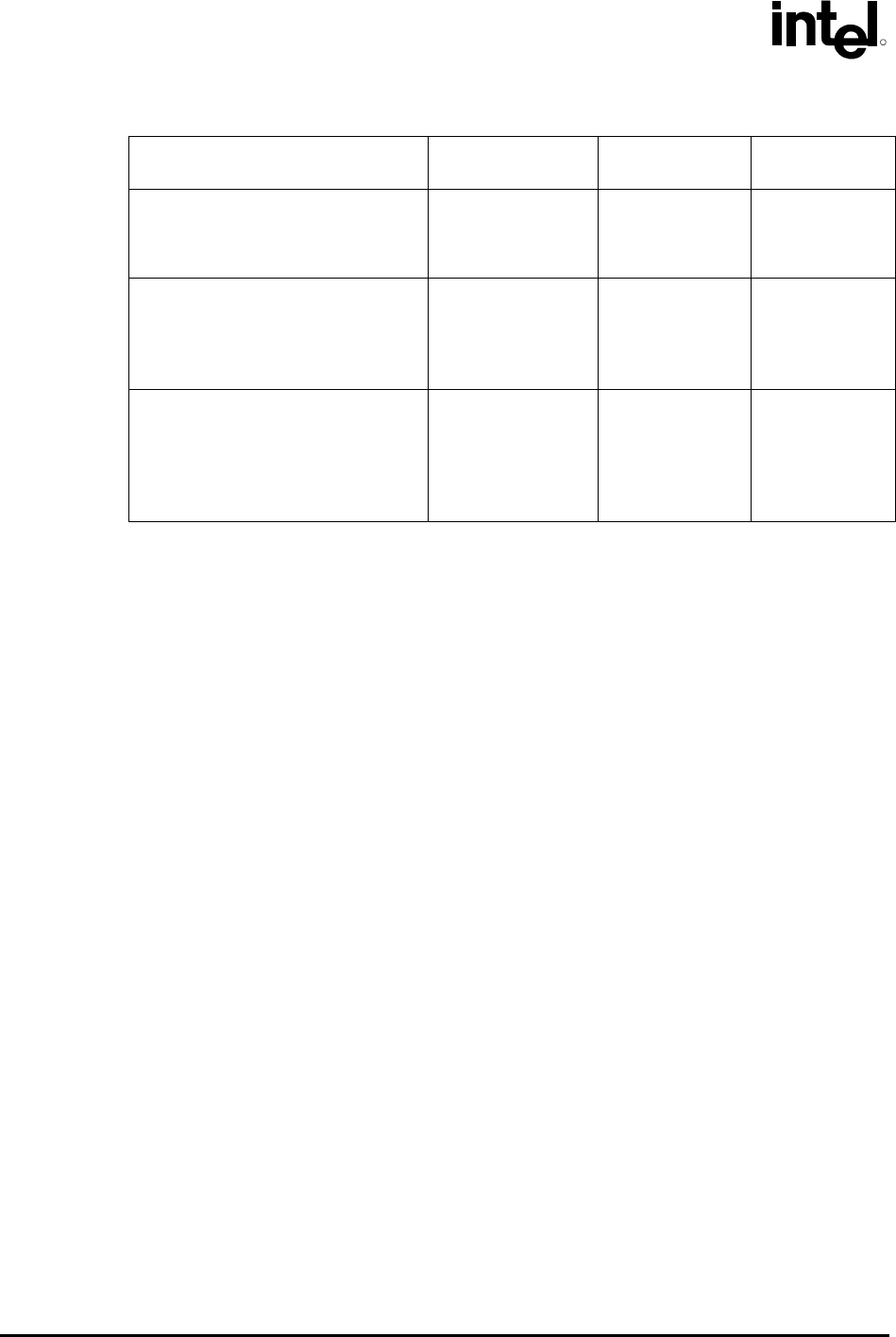

Table 5-1. Use Conditions Environment (Continued)

Use Environment

Speculative Stress

Condition

7 Year Life

Expectation

10 Year Life

Expectation

Fast, large gradient on/off to max

operating temp. (power cycle or

internally heated including power save

features).

Power Cycle 7,500 cycles 11,000 cycles

Shipping and Handling. Mechanical Shock

50g trapezoidal

profile; 170”/sec

Velocity change; 11

msec duration pulse

3 drops / axis 6

axis

Shipping and Handling. Random Vibration

3.13 gRMS, random,

5 Hz - 20 Hz .01

g2/Hz sloping up to

.02 g2/Hz 20 Hz -

500 Hz .02 g2/Hz

10 min / axis, 3

axis

5.1 Porosity Test

5.1.1 Porosity Test Method

Use EIA 364, Test Procedure 53A, Nitric acid test. Porosity test to be performed for 20 contacts,

randomly selected per socket, five sockets.

5.1.2 Porosity Test Criteria

Maximum of two pores per set of 20 contacts, as measured per EIA 364, Test Procedure 60.

5.2 Plating Thickness

Measure various plating thickness on contact surface per EIA 364, Test Procedure 48, Method C or

Method A. Test to be performed using 20 randomly selected contacts per socket, five sockets. No

plating thickness measured shall be less than the minimum plating thickness specified in

Section 3.9.3.

5.3 Solvent Resistance

Requirement: No damage to ink markings if applicable. EIA 364-11A.

5.4 Solderability

(Applicable for leaded sockets) Requirement: 95% coverage per ball/surface mount feature. EIA

364, Test Procedure 52, Class 2, Category 3. Test to be performed on 20 randomly selected contacts

per socket, five sockets.