121

ENGLISH

3

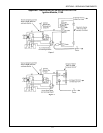

I. PREPARATION AND DISASSEMBLY

1. Turn off the electric power supply to the oven.

2. Turn off the gas supply at the service valve behind the

oven.

3. Open the machinery compartment door.

4. Open the union in the gas supply line. The union is

located on the inlet side of the combination gas control

valve. See Figure 1.

5. Unscrew the four hex screws that hold the venturi

mounting plate to the front of the burner. Remove the

gas train/venturi assembly from the oven.

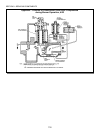

II. COMBINATION GAS CONTROL VALVE (SAFETY

REGULATOR) CONVERSION

1. Remove and discard the following components from the

combination gas control valve, as shown in Figure 2:

Regulator cap screw

Regulator adjustment screw

Regulator spring

2. Install the red kit-supplied regulator spring, with the

tapered end facing into the valve, as shown in Figure 2.

3. Install the white kit-supplied regulator adjustment screw.

Carefully adjust the screw until its top is flush with the

top of the regulator.

4. Turn the adjustment screw six complete turns in a

clockwise direction. This preliminary pressure setting

is approximately 10-1/2 W.C. (26.1mbar).

5. Install the black kit-supplied cap screw.

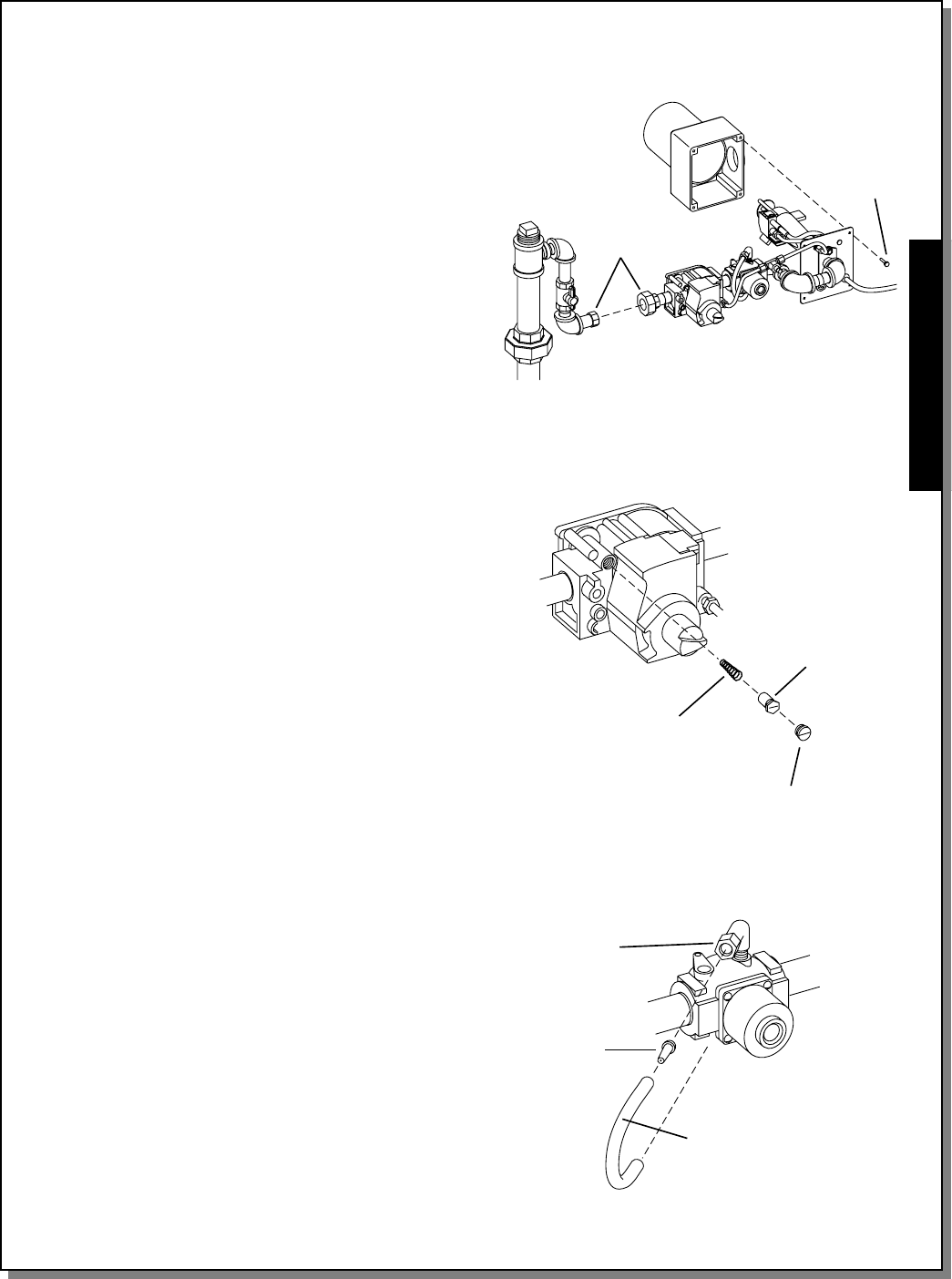

III. BYPASS ORIFICE CONVERSION

NOTE: Ovens are equipped with EITHER an on-off solenoid

valve with a separate bypass line, OR with a modulating gas

valve. Refer to the illustrations on Page 2. When installing

this Kit, the bypass orifice will only be changed if the oven

is equipped with a solenoid valve.

If the oven is equipped with a modulating gas valve, skip

ahead to Section IV, Pilot Orifice Conversion.

If the oven is equipped with a solenoid valve, continue on

to Step 1, below.

1. Unscrew the compression nuts at both ends of the

bypass tube, and slide them back and out of the way.

Then, remove and retain the tubing. See Figure 3.

2. Remove and discard the existing bypass orifice.

3. Slip the kit-supplied bypass orifice into the discharge

end of the bypass tube, as shown in Figure 3.

4. With the orifice in place, push the tube back into the

compression fittings until it bottoms.

5. While holding the tube in place, slide the compression

nuts into place. Tighten them to a snug fit with your

fingers.

6. Gently tighten the nuts one complete turn with a

wrench. DO NOT OVERTIGHTEN THE COMPRESSION

NUTS.

Figure 1

Gas pipe

union

PS570S gas train (with solenoid valve) shown.

Refer to the illustrations on Page 2 for

component placement for other oven models.

Hex

screws

Figure 2

Regulator

spring

Adjustment

screw

Cap screw

Figure 3

Bypass

tube

Bypass

orifice

Compression

nut

SECTION 3 - SERVICING COMPONENTS

Appendix - Instructions for All Gas Conversion Kits

for Ovens with Wayne Burner, Natural Gas to Propane, 8/00