69

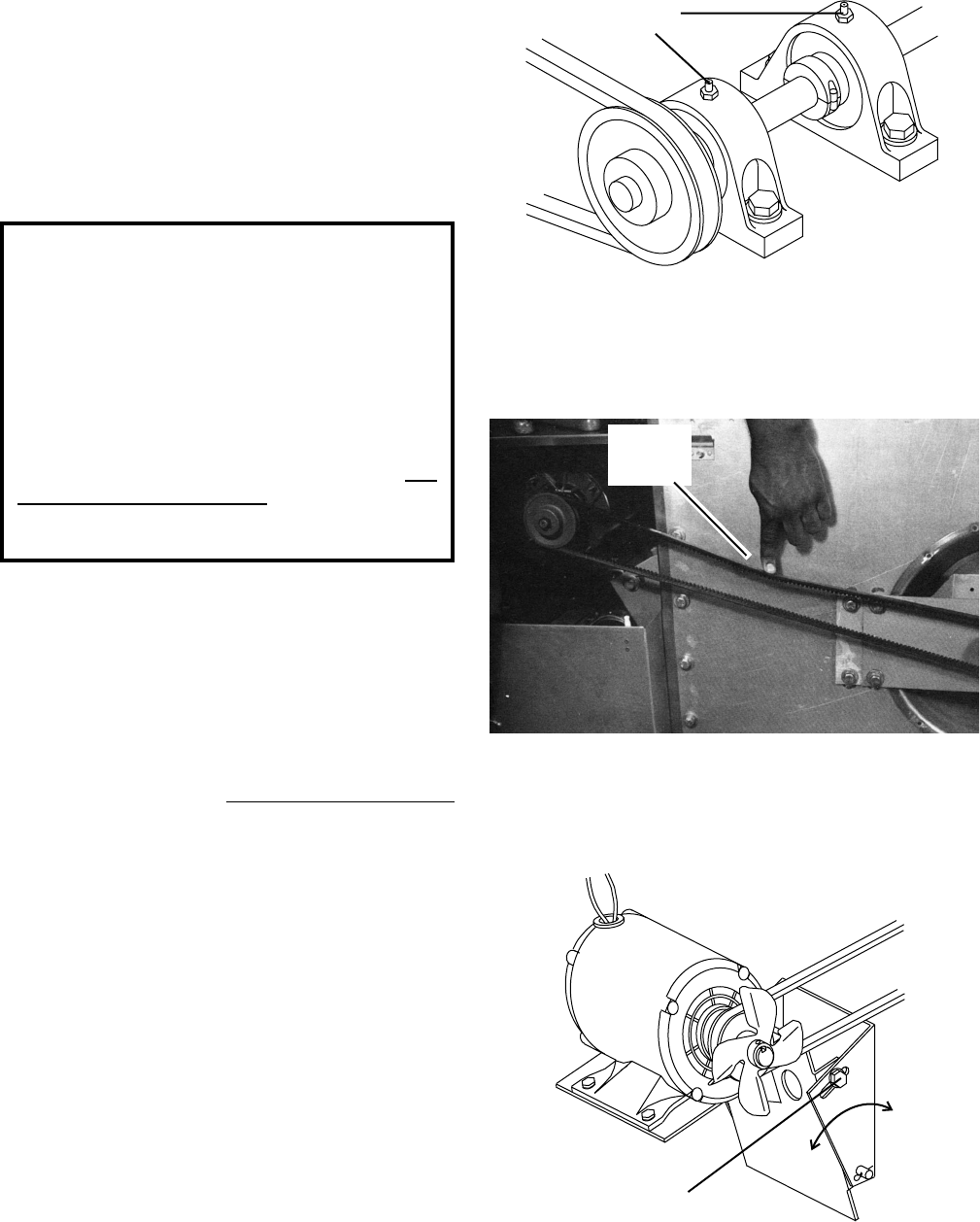

3. Lubricating the blower fan shaft bearings

NOTE: Middleby recommends lubricating the blower

fan shaft bearings every three months.

Use a grease gun to lubricate the main blower fan shaft

bearings. See Figure 28. When lubricating the bear-

ings:

Use a high-quality NLGI #2, lithium soap grease with

petroleum oil, such as Middleby P/N 17110-0015.

Add the grease slowly until a small bead of grease

is present at the seals. AVOID OVERGREASING.

Excessive greasing may cause harm to the bearing.

Manually turn the blower shaft by pulling on the belt to

purge the grease. Wipe off any excess grease. The

oven cannot be operated until the rear shroud is replaced.

4. Blower belt tension

NOTE: Middleby recommends checking the blower

belt condition and tension every three months.

Check the blower belt for at least 1" (25mm) deflection

at the center, and for cracking or excessive wear.

Overtightening the belt will cause premature bearing

failure and possible vibrations. See Figure 29.

If necessary, adjust the tension of the belt by loosening

the two motor mounting bolts as shown in Figure 30.

Reposition the motor as neccessary until the correct

deflection is reached, then tighten the bolts.

IMPORTANT: Middleby uses two different types

of grease in blower shaft bearings:

DuPont Krytox® grease is used in some

PS536 ovens. Refer to Service Bulletin MM-

192 (included in the Appendices section of

this chapter) for details on identifying

Krytox® bearings.

All other ovens use the standard Middleby

high-temperature grease, P/N 17110-0015.

Mixing grease types within the bearing will

cause the bearing to seize. For all PS200 ov-

ens, be sure to use ONLY the standard

Middleby grease.

Figure 28

Bearing lubrication

Grease fittings

(1 per bearing,

2 total)

Figure 30

Repositioning the blower motor

Loosen bolts to

reposition motor

and adjust belt

tension

Figure 29

Blower belt tension

1 (25mm)

vertical

deflection

2. Blower balancing and direction of rotation

Proper blower rotation is extremely important. From

the rear of the oven, the blower shaft pulley should turn

in a clockwise direction. See Figures 25 and 26.

All blower fans are balanced at the factory. Any fan

found to be out of balance should be replaced. Vibra-

tion from an out-of-balance fan can cause poor baking

and premature bearing failure. Note that vibrations can

also be caused by other sources, including defective

motor or blower shaft bearings, loose bearings or mo-

tor mounting bolts, or an incorrectly tensioned fan belt.

SECTION 3 - SERVICING COMPONENTS