129

ENGLISH

5

VII. GAS LEAK TEST

1. Restore the electrical and gas utility connections to the

oven.

2. Paint all gas pipe connections from the union to the

venturi mounting plate, as well as the pilot tubing,

bypass tubing, and pressure tap plug, with a rich

solution of soap and water (2/3 soap, 1/3 water is

recommended). Any visible bubbles indicate a gas

leak.

3. If a gas leak is detected, tighten the affected joints and

connections. If tightening the connection(s) fails to stop

the leak:

Turn off the electric power supply to the oven.

Turn off the gas supply at the service valve behind

the oven.

Replace the affected component(s).

Repeat the gas leak test.

WARNING - FIRE/EXPLOSION HAZARD

HIDDEN GAS LEAKS CAN CAUSE A FLASHBACK

IN THE MACHINERY COMPARTMENT. THIS

CAN CAUSE SEVERE INJURY OR DEATH.

STAND WELL CLEAR WHEN SWITCHING ON

THE HEATING CIRCUIT.

4. If no leaks are detected by the test, depress the safety

switch(es) and switch on the oven. Then, switch on the

heating circuit to ignite the burner.

5. With the burner in operation, paint all gas pipe joints with

the solution of soap and water.

6. If any further gas leaks are detected, shut down the

oven. Reseal and tighten the affected joints and

connections. If tightening the connection(s) fails to stop

the leak:

Turn off the electric power supply to the oven.

Turn off the gas supply at the service valve behind

the oven.

Replace the affected component(s).

Repeat the gas leak test.

VIII. INLET PRESSURE CHECK

1. Using a manometer, check the inlet pressure at the inlet

pressure tap. See Figure 6. An inlet pressure of 6-12

W.C. (14.9-29.9mbar) is recommended for natural gas

operation.

2. If the inlet pressure is:

HIGHER THAN 14 W.C. (34.9mbar) - This pressure

may damage the combination gas control valve

(safety regulator). The gas supply pressure should

be decreased.

LOWER THAN 6 W.C. (14.9mbar) - It may be

necessary to increase the supplied gas pressure.

CAUTION

IF IT IS NECESSARY TO ADJUST THE GAS LINE

PRESSURE, HAVE THE CUSTOMER CONTACT THE

GAS UTILITY SUPPLIER.

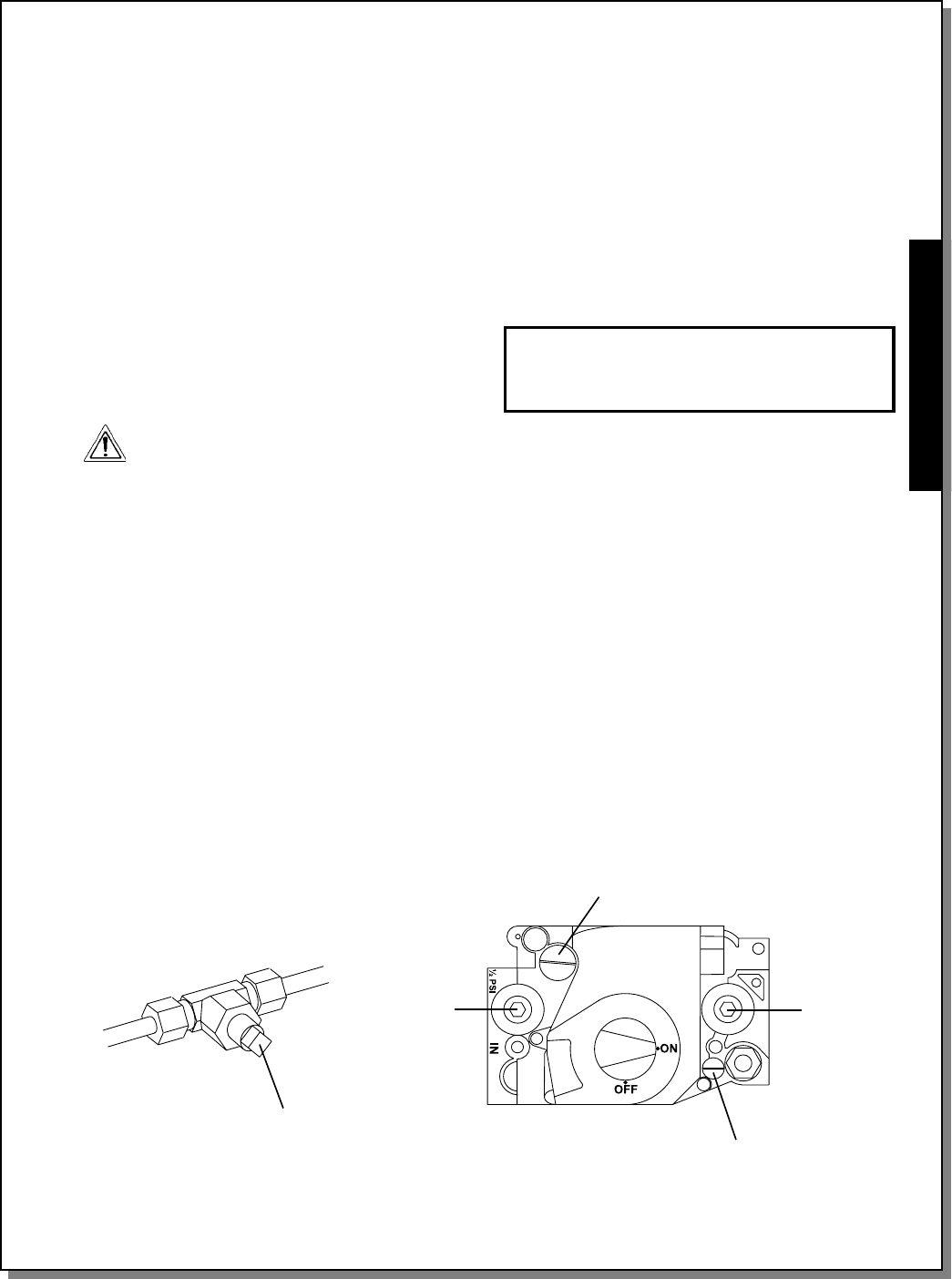

Figure 6

Measure pilot

pressure here

(under cap plug)

Adjust pilot

pressure here

(under cap screw)

Measure inlet

pressure here

Measure

manifold

pressure here

Adjust manifold

pressure here

(under cap screw)

IX. PILOT PRESSURE ADJUSTMENT

1. Unscrew the cap plug from the pilot pressure tap (pilot

tee), and attach a manometer to the tap. See Figure 6.

2. Remove the pilot adjustment cap screw from the

combination gas control valve.

3. Turn the oven on, and allow it to heat to temperature.

Make a note of the customers set point temperature.

4. After the oven has heated, adjust the set point of the

oven far lower than its current (operating) temperature.

This ensures that the pilot flame will be at its lowest level

for some time.

Continued...

SECTION 3 - SERVICING COMPONENTS

Appendix - Instructions for All Gas Conversion Kits

for Ovens with Wayne Burner, Propane to Natural Gas, 8/00