130

ESPAÑOL

- página 7

ENGLISH

- page 1

6

5. The pilot pressure should be adjusted as follows:

The current flow between the pilot hood and the

flame sensor, when measured with a microamp

meter or multimeter, holds constant at a minimum

of 2.0 µA. See Figure 7.

The pilot pressure as shown on the manometer is in

the range of 3-1/2 - 4 W.C. (8.7-10.0 mbar).

Adjust the pilot pressure as necessary by turning the

pilot adjustment screw on the combination gas control

valve. Turning the screw clockwise decreases the pilot

pressure. Turning the screw counter-clockwise increases

the pressure.

Some valves may have a burr in the pilot adjustment

portal. If you have fully tightened the adjustment screw,

and the manometer still does not register a change in

pressure, continue to tighten the screw to break through

the burr. Back the screw out until its top is flush with the

top of its hole, then tighten the screw again as necessary

to adjust the pressure. Repeat this procedure as

necessary to properly adjust the pilot pressure.

If the pilot pressure cannot be properly adjusted, switch

the oven off and allow it to cool; then, replace the

combination gas control valve. Repeat Section VII (Gas

Leak Test) before attempting to adjust the pilot pressure

again.

7. After the pilot pressure has been properly adjusted,

replace the cap screw.

8. Reset the ovens set point temperature to the customers

original settings. Leave the oven in operation to allow

the manifold pressure to be checked in the next Section

of these instructions.

X. MANIFOLD PRESSURE ADJUSTMENT

1. Remove the regulator cap screw from the combination

gas control valve.

2. Using a manometer, check the pressure at the manifold

pressure tap, as shown in Figure 6. A manifold pressure

of 3-1/2 W.C. (8.7mbar) is recommended for natural

gas operation.

3. Adjust the pressure as necessary by turning the

adjustment screw on the combination gas control valve.

Turning the screw clockwise decreases the pressure.

Turning the screw counter-clockwise increases the

pressure.

If the manifold pressure cannot be properly adjusted,

switch the oven off and allow it to cool; then, replace the

combination gas control valve. Repeat Section VII (Gas

Leak Test) before attempting to adjust the manifold

pressure again.

4. After the manifold pressure has been properly adjusted,

replace the cap screw. Record the final value on the Gas

Conversion Label, as shown in Figure 8.

5. Switch the oven off, and allow it to cool.

XI. MARKING AND LABELING

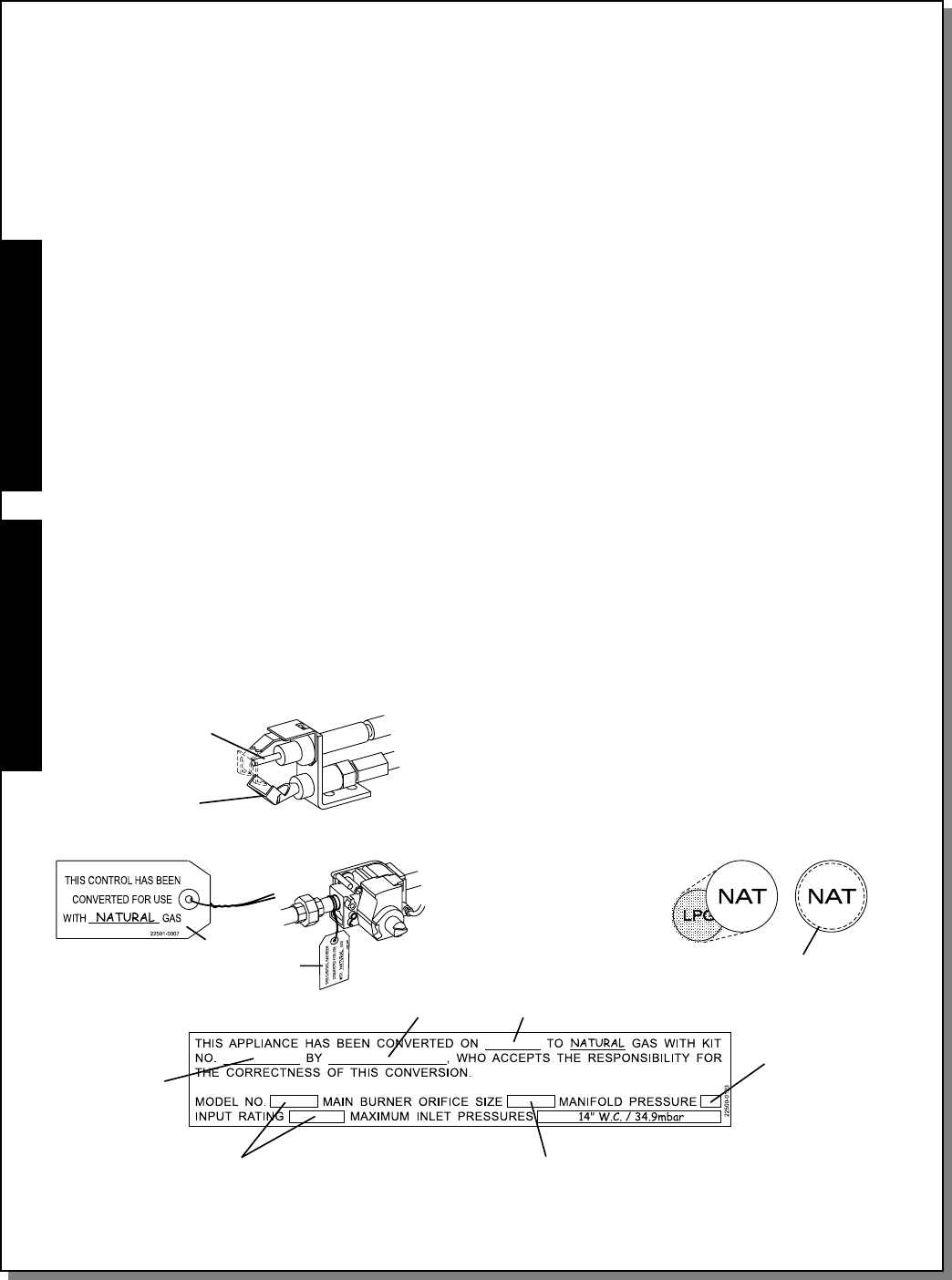

1. Print the word NATURAL in the space provided on the

Gas Control Conversion Tag, P/N 22501-0007. See

Figure 8. Fasten the tag onto the gas piping next to the

combination gas control valve.

2. Locate the round LPG label (red) on the burner or

burner motor. Attach the kit-supplied yellow/green

NAT label, P/N 22500-0064, on top of the LPG label.

The new label should completely cover the LPG label.

See Figure 8.

3. Complete the information on the Gas Conversion Label

as shown in Figure 8.

4. Attach the Gas Conversion Label in plain view on the

outside of the oven, as close as possilble to the ovens

serial plate.

Figure 8

Attach to gas

piping next to

combination

gas valve

Attach on top of

existing LPG

label (on burner or

burner motor)

Date of

conversion

Measured value

from Section X

See chart on

Page 1

Stated on the ovens

serial plate

Part no. of this

Kit - see chart

on Page 1

Name of

technician

Attach completed label in plain

view near serial plate

New label completely

covers LPG label

Figure 7

Pilot hood ( - )

Flame sensor ( + )

SECTION 3 - SERVICING COMPONENTS

Appendix - Instructions for All Gas Conversion Kits

for Ovens with Wayne Burner, Propane to Natural Gas, 8/00