95

SECTION 3 - SERVICING COMPONENTS

E. Burner Blower Motor

The burner blower motor is located on the side or top of the

burner housing. Some blowers use a flexible tube to con-

nect the blower to the burner, depending on the available

space inside the machinery compartment. The burner

blower motor drives a blower wheel located in a housing

attached to the end of the motor that is the primary air

supply for combustion. The motor requires no lubrication.

Depending on the oven model, the burner motor operates

on either 120V or 208/240V (line voltage). 120V motors

have an internal centrifugal switch that controls the 24V

power supply to the gas valve (see Burner Blower Motor

Centrifugal Safety Switch on Page 80). 208/240V motors

use a separate air pressure safety switch to sense blower

operation (see Air Pressure Safety Switch on Page 81).

This safety feature prevents burner operation in case of motor

failure.

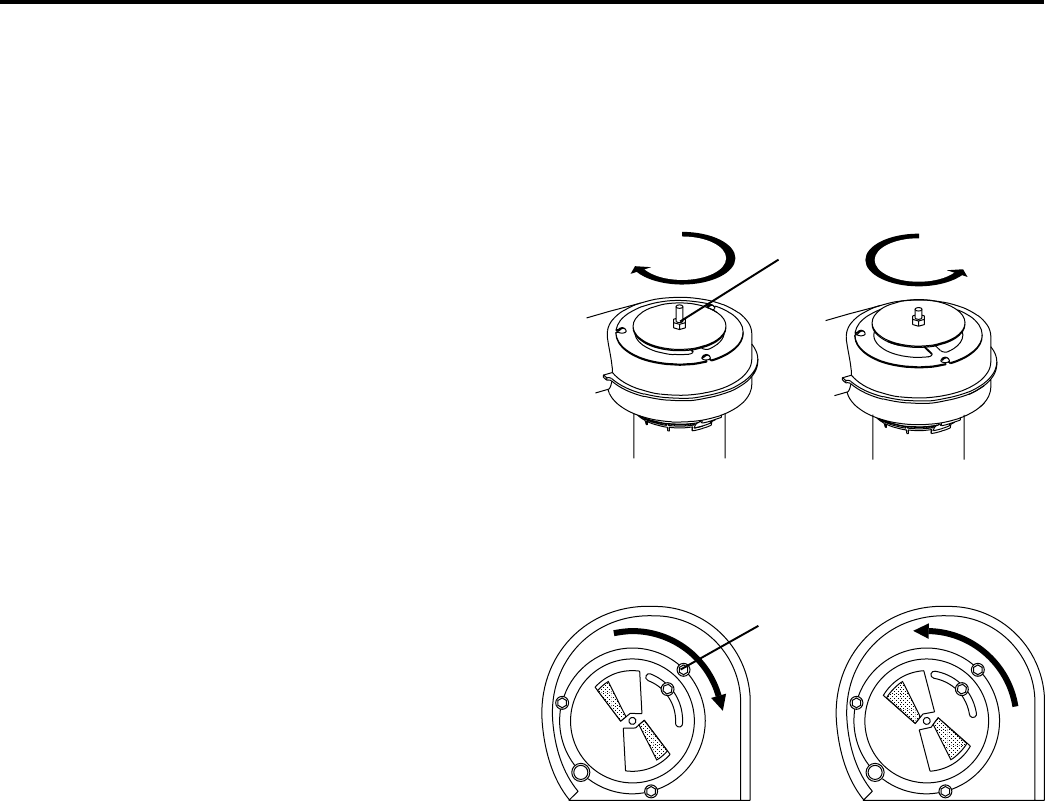

F. Air Shutter

The air shutter is a round metal plate located on the open

end of the burner blower wheel. Adjusting the position of

the shutter will increase or decrease the amount of air that

is permitted into the plenum for combustion. Rotate the

plate in a counterclockwise direction to increase the air

supply, or in a clockwise direction to reduce the air supply.

You can insert a drill bit into the shutter gap to check the

size of the opening. Refer to Figure 69 for the recommended

opening sizes.

Early Midco burners use an adjustment screw on the front

wall of the plenum to adjust the airflow. If it is not possible

to adjust the air supply properly using the screw, a retrofit

kit is available (P/N 36829) to install the external air shutter

shown in Figure 69.

Figure 69

Air shutter adjustment

Counter-

clockwise -

more air

Clockwise -

less air

Wayne burner

Standard openings:

1/4/6.4mm for natural gas ovens

3/8/9.5mm for propane ovens

Midco burner

Standard opening 5/16/7.9mm (all gases)

Loosen

screw to

adjust

shutter

Loosen hex

nut to adjust

shutter

Clockwise -

less air

Counterclockwise -

more air

In these cases, the pilot may ignite, but the main burner

gas valve will not be energized. It is also possible for

drafts or unusual air currents to deflect the pilot flame

away from the flame sensor. Deflection of the pilot

flame may also be caused by main burner ignition con-

cussion or roll-out of the main burner flame.

An additional point to be considered is the condition of

the pilot flame. If the pilot flame is hard and blowing,

the grounding area of the pilot is reduced to a point

where the necessary current is not being maintained,

and a shutdown of the system will result.

The positioning of the flame sensor is also critical in

the pilot application. Positioning of the flame sensor

should be such that it will be in contact with the sec-

ond, or combustion area of the pilot flame. Passing

the flame sensor through the inner cone of the pilot

flame is not a recommended procedure. For this rea-

son, a short flame sensor may provide a superior sig-

nal over a longer one. The final determination of the

sensor location (length) is best determined by the use

of a multimeter set to read microamps (mA).

Temperature

Ignition controls should not be exposed to tempera-

tures exceeding 140°F (60°C) or less than -40°F (-40°C).

Pilot Application

The pilot and flame sensor application is the most criti-

cal aspect of the llD application.

The pilot flame must make contact with the pilot tip

and surround the flame sensor probe. A multimeter or

ampmeter set to read microamps (mA) is necessary to

verify that the proper amount of current is being main-

tained through the pilot flame. The minimum value

required is 2.0 mA. Rectification-based ignition sys-

tems respond in less than 0.8 of a second to a loss of

flame. If the minimum signal is not being maintained

at all times, OR if the pilot flame is briefly directed

away from the flame sensor or pilot tip, the main gas

valve may cycle rapidly (chattering) or the burner may

be prevented from activating.

Other conditions that can cause the failure of the main

burner to activate, OR chattering of the burner, are:

1. Pilot flame is too small.

2. Gas pressure is too low for proper pilot flame im-

pingement on the flame sensor.