72

6. Current-style PS200 bearing replacement and alignment

NOTE: This procedure is for current-style indirect fan

shaft assemblies only, as shown in Figure 26. Bearing

replacement procedures for the early-style indirect fan

shaft assembly (Figure 25) are provided on Page 70.

The following procedures are necessary to align the

fan shaft whenver service to the fan shaft or replace-

ment of the bearings is required. REFER TO FIGURE

34 FOR ILLUSTRATIONS OF THE COMPONENTS DE-

SCRIBED HERE.

1. Remove the entire back wall (Item 1) of oven to

service the fan assembly.

2. Remove the blower fan (Item 11) and pulley (Item

7).

3. Remove the indirect drive bracket assembly (Item

5) by removing eight (8) screws (Item 2). lf you are

upgrading from the early-style assembly, save the

hardware (Items 2, 3, 4, and 12) to be reused with

the new style bracket (Item 5).

NOTE: If parts are to be replaced, you should replace

them now.

4 Install front and rear fan shaft pillow block bearings

(Item 9), if they were removed, to indirect drive

bracket (Item 5) using two (2) 3/8-16 X 1 screws

(Item 2) and two 3/8 lockwashers (Item 10) on each

bearing.

NOTE: Do not tighten the pillow block bearings

until Step 7 has been completed.

5. Install the fan shaft (Item 6) as illustrated in Figure

34. Align bearing set screws with flats on shaft but

do not tighten set screws at this time.

NOTE: Before proceeding to Step 6, it is advisable to

position the rear wall assembly in an upright, vertical

position using a block of wood under the fan ring.

6. When installing the drive bracket (Item 5) insert

one 3/8 flat washer (Item 4) at the four outer holes

and one 3/8 special flat washer (Item 12) at the 4

inner holes between the bracket and back wall at

the mounting locations. Use eight 3/8-16 X 1

screws (Item 2) and assemble a 3/8 lockwasher

(Item 3) and a 3/8 flat washer (Item 4) into each

screw. Insert a screw at all 8 locations. Hand

tighten only at this time.

7. Insert fan shaft alignment tool (Item 13) as shown

into back wall.

NOTE: The bracket assembly is designed for slight up

and down and right to left movement to attain free shaft

rotation when the shaft alignment tool is in place. Once

free shaft rotation is achieved, tighten all eight bracket

screws (Item 2).

8. Tighten rear pillow block bearing screws (Item 9)

then front pillow block bearing screws.

9. Remove shaft alignment tool, then recheck fan shaft

for free rotation.

10. Install pulley (Item 7) on fan shaft and position fan

shaft per dimension shown in Figure 34. Align the

flats machined on fan shaft with the bearing set

screw holes. Apply High Temperature Loctite, type

RC 620 on bearing set screws and then tighten set

screws. Recheck fan shaft for free rotation.

11. Apply anti-seize compound on fan shaft before in-

stalling fan blade (Item 11). Position fan blade flush

with 5/8 shoulder on shaft as called out in Figure

34.

NOTE: Fan blade hub has a 1/2 bore. The fan shaft

is turned down from 5/8 to 1/2 to receive fan blade.

12. Apply High Temperature Loctite Type RC 620 to

fan blade set screws.

NOTE: Tighten the two set screws on fan blade per

the following sequence when viewing fan blade from

front: first, the screw at the 12:00 position, then the

screw at the 3:00 position.

13. Recheck fan shaft rotation before installing back

wall to oven cavity. Be sure fan assembly has ad-

equate clearance inside orifice ring and is not rub-

bing.

NOTE: Apply anti-seize compound (MM P/N 17110-

0017) to all 12 bolts before installing back wall assem-

bly to oven.

14. Install back wall on oven.

15. Check motor pulley and fan pulley alignment. See

Figure 33.

16. Install fan belt.

NOTE: Excessive fan belt tension will create overload-

ing of rear bracket fan shaft bearing. Refer to Blower

Belt Tension on Page 69.

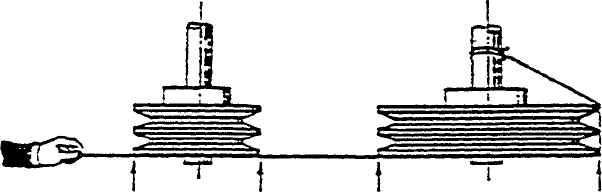

Figure 33 - Four-point alignment test for correct pulley alignment

Cord tied to shaft

Cord must touch sheaves at four points indicated by arrows

SECTION 3 - SERVICING COMPONENTS