97

SECTION 3 - SERVICING COMPONENTS

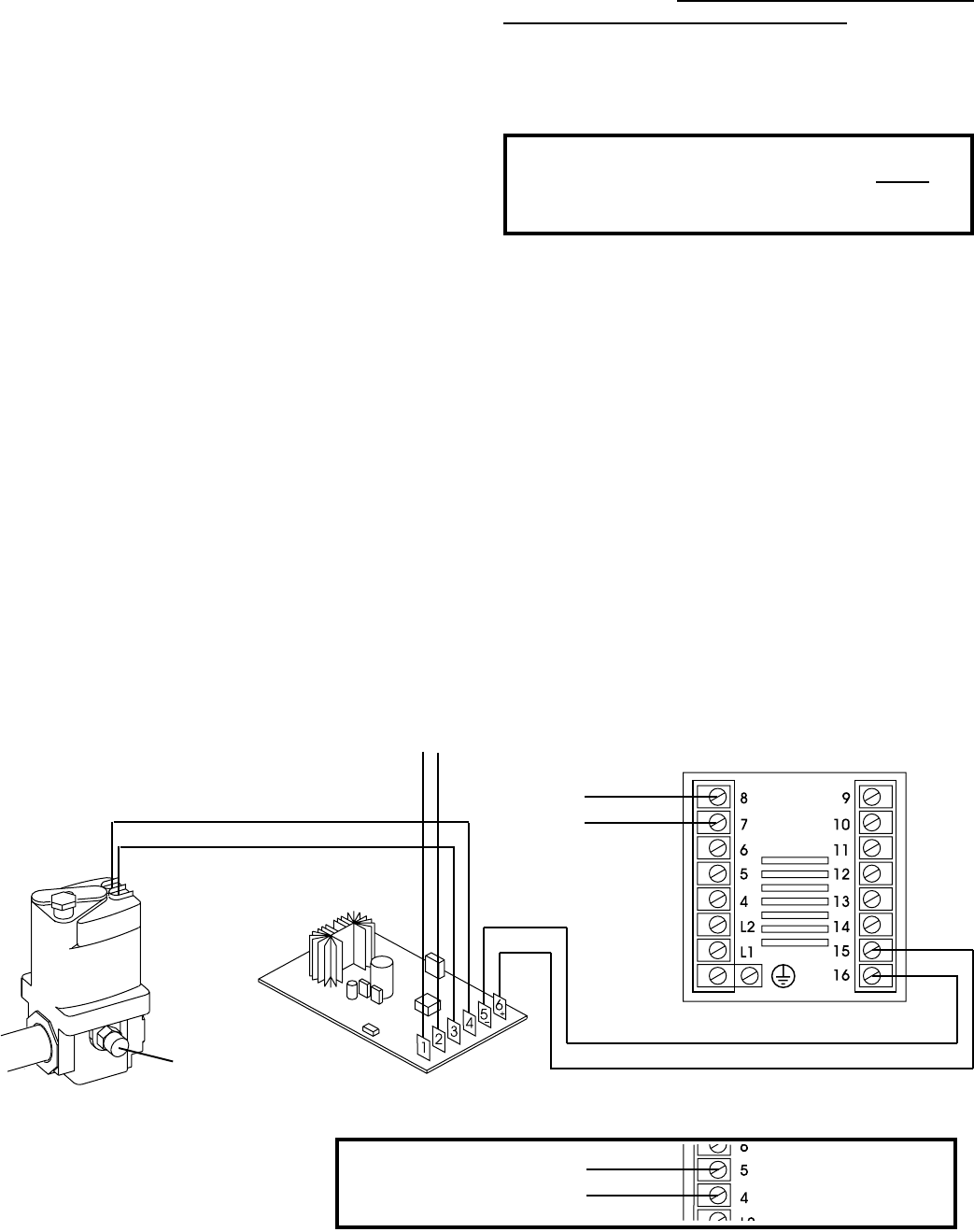

Digital Temperature

Controller

MUST BE SET TO PID

OPERATING MODE

Amplifier Board

Modulating Valve

To thermocouple

white +

red -

purple

To transformer

24VAC input

purple/white

blue

blue/white

orangeorange/white

bypass adjustment

screw (under cap)

MUST BE FULLY

CLOSED

Figure 71 - Modulating Gas System

K. Modulating Gas Valve (if so equipped)

Ovens that use a PID (modulated) gas regulation system

are equipped with a modulating gas valve instead of a sole-

noid valve. The valve is located between the combination

gas control valve and the burner.

In response to the millivolt signal from the thermocouple,

the Digital Temperature Controller sends a 4-20mA signal

to an amplifer board. The board, in turn, passes on a 0-

20VDC signal to the modulating valve itself. The valve opens

or closes proportionally to the signal from the amplifier board,

allowing any setting from 0-100% gas flow.

When the oven is switched on, gas demand is at its peak

and the valve is fully open, permitting 100% gas flow. As

the ovens temperature approaches the set point, the valve

slowly begins to close, restricting gas flow to the 35-60%

range. After the oven is fully preheated, the gas flow usu-

ally stabilizes at about 30%. The actual oven temperature

can remain constant, with NO temperature swing, because

the valve is adjusted constantly according to the demand.

Modulating valves are used on all PS360EWB, PS555, and

PS570G gas ovens. They are also used on PS200 ovens

produced 4/02 or later and PS570S ovens produced 9/00 or

later.

The Model PS360EWB oven uses a Maxitrol M520 modu-

lating valve with a 3/4 gas line, P/N 32570. All other

Middleby oven models equipped with a modulating valve

use the Maxitrol M420 valve with a 1/2 gas line, P/N 41647.

The modulating valve features a bypass adjustment screw,

shown in Figure 71. For all ovens except the PS536, the

screw should ALWAYS remain fully closed; no adjustment

is necessary. The screw is pre-set to the fully-closed posi-

tion from the factory. If the screw is adjusted to any setting

other than fully-closed, the oven may not be able to main-

tain the set point temperature.

IMPORTANT: For proper functioning of the modu-

lating valve, the temperature controller MUST be

set to the PID operating mode. Refer to Tempera-

ture Controller on Page 31.

L. Amplifier Board (ovens with a modulating gas

valve only)

Ovens equipped with a modulating gas valve have an ampli-

fier board mounted inside the machinery compartment.

In response to the millivolt signal from the thermocouple,

the Digital Temperature Controller sends a 4-20mA signal

to the amplifer board. The board, in turn, passes on a 0-

20VDC signal to the modulating valve. The valve opens or

closes proportionally to the signal from the amplifier board,

allowing any setting from 0-100% gas flow.

All Middleby oven models equipped with a modulating valve

use amplifier board P/N 31651.

PS360EWB

with Controller 32571

only

purple/white

purple

To amplifier board terminal 6

To amplifier board terminal 5