5

5 - 15

W-2WAY ECO-i SYSTEM

Trouble Diagnosis

4. W-2WAY ECO-i Alarm Codes

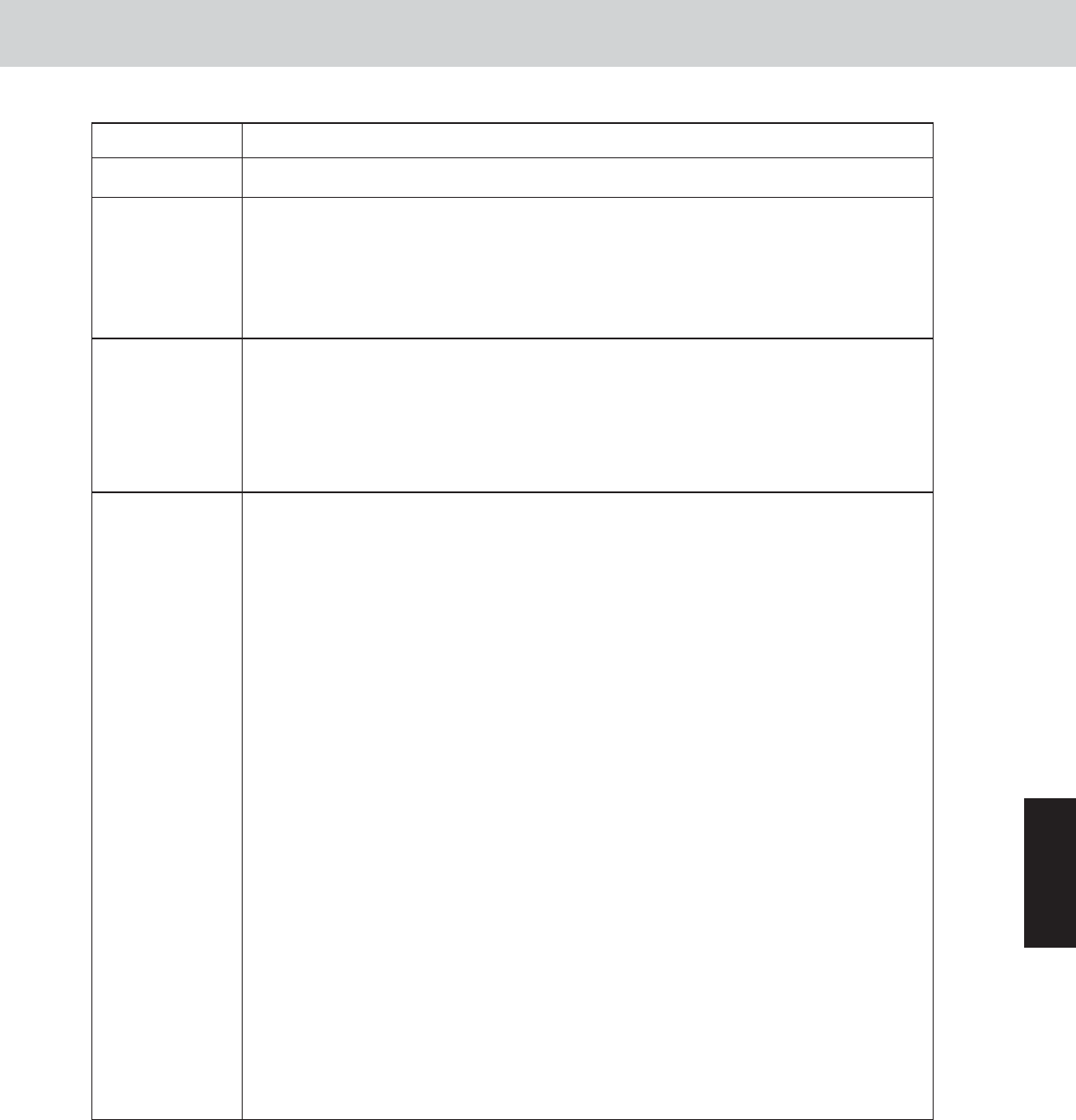

F16 Alarm

Alarm code F16

Alarm meaning High-pressure sensor trouble (abnormal rise in high pressure) (In some cases this may not be

the result of a high-pressure sensor malfunction.)

Alarm conditions High-pressure SW activated although the detected pressure was lower (439.4 psi or below)

than the high-pressure SW activation pressure: Undershift

High-pressure SW failed to activate although the detected pressure was higher (497.5 psi or

above) than the high-pressure SW activation pressure: Overshift

The saturation temperature at the detected pressure is 10°F or more below the highest indoor-

unit E1 temperature continuously for 30 minutes.

High-pressure sensor disconnected or open circuit.

•

•

•

•

Probable cause (1) High-pressure sensor malfunction

(2) Failure to connect the connector to the outdoor unit PCB

(3) Failure to open the service valve

(4) Clogged tubing

(5) Valve leakage

(6) Over-charging

(7) Outdoor unit PCB failure

(8) Electrical noise

Check (1) High-pressure sensor failure

Check the sensor resistance value. (Use a tester and measure the resistance between

sensor No. 1 and No. 3)

Resistance of less than 10k

Ω

indicates a short circuit or other trouble.

Resistance of 10k

Ω

- 200k

Ω

is normal. Resistance of more than 200k

Ω

indicates

an open circuit or other trouble.

Connect a gauge to the high-pressure outlet and check for changes in

the value

dispalyed by the monitoring software, and for large deviation of the gauge pressure.

During heating, check whether the temperature is lower than the highest indoor-unit E1

temperature.

* The pressure detected by the high-pressure sensor is the highest pressure in the system.

Therefore during heating the converted saturation temperature will never be lower than

any indoor-unit E1 temperature. During cooling this temperature will never be lower

than the outdoor unit liquid temperature.

(2) Failure to open the service valve, clogged tubing, valve leakage, over-charging.

In all of these cases an alarm occurs when there are rapid pressure fluctuations and tracking

of the detected pressure is poor.

Check the open/closed status of the valve.

Check for clogging of the tubing.

To check for clogging, disconnect the high-pressure sensor from the PCB and check

whether the high-pressure SW activates.

Check for valve leakage and over-charging

When valve leakage or over-charging occurs, refrigerant is likely to accumulate in the

outdoor units or indoor units, resulting in a sudden rise in pressure at start that occurs

before the refrigerant in the heat exchanger is discharged.

* The representative valves to check are the liquid valves and mechanical valves.

(3) Outdoor unit PCB failure

The check items are the same as for a high-pressure sensor malfunction.

A normal PCB is needed to determine whether the problem is a PCB failure or a pressure

sensor malfunction. If an abnormality was found at the check items for a high-pressure

sensor malfunction, first try replacing the PCB and check again.

Trouble is corrected: Outdoor unit PCB failure

Trouble is not corrected: High-pressure sensor malfunction

•

•

•

•

•

•

•

Continued