5

5 - 23

W-2WAY ECO-i SYSTEM

Trouble Diagnosis

4. W-2WAY ECO-i Alarm Codes

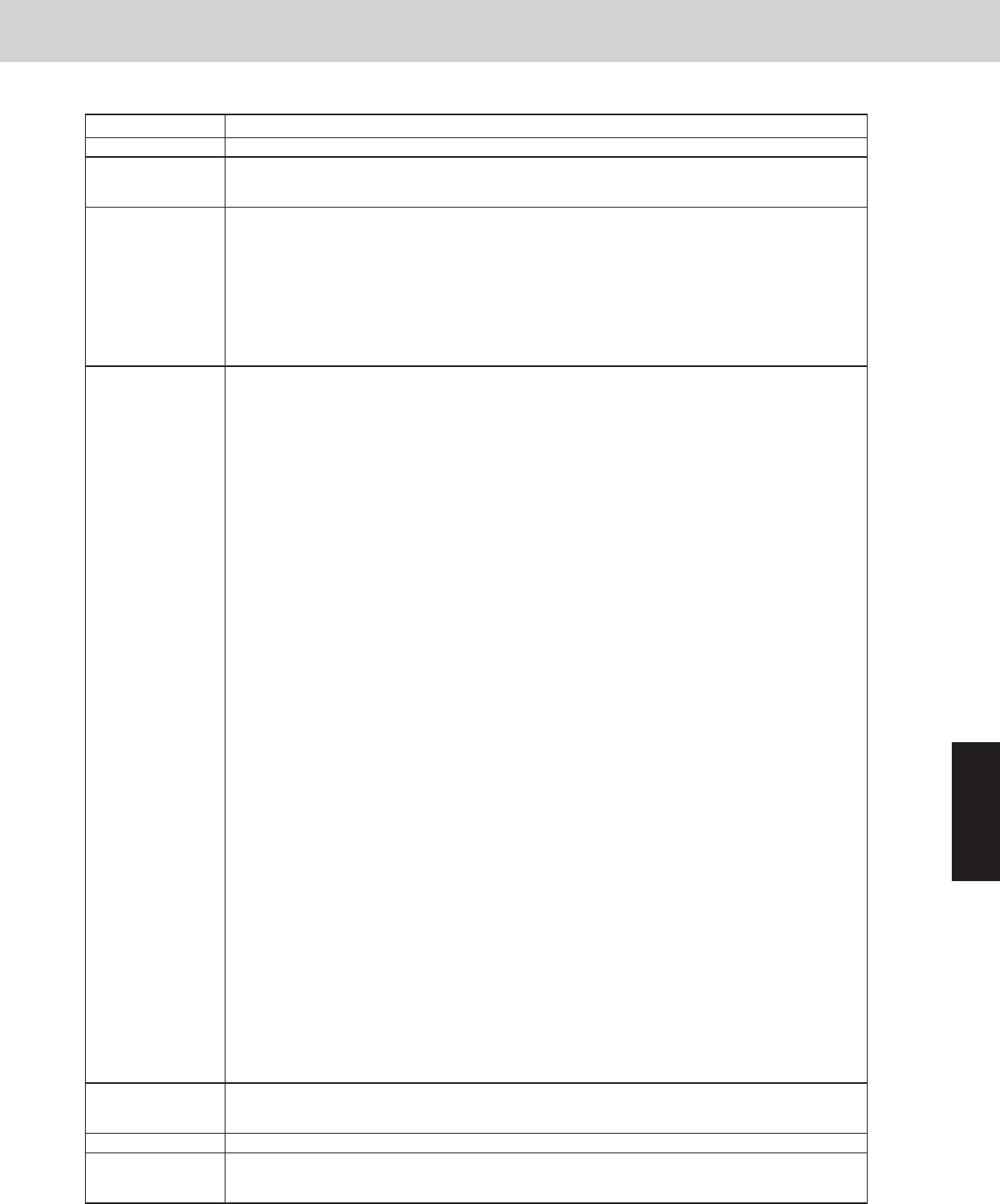

P03, P17 Alarm

Alarm code P03, P17

Alarm meaning Compressor 1 discharge temperature trouble; Compressor 2 discharge temperature trouble

Alarm conditions Temperature is 222°F or higher and pre-trip stop has occurred.

The alarm occurs when pre-trip stop occurs more than once. However the pre-trip counter is

cleared if the compressor operates continuously for a specified length of time.

Probable cause (1) Clogging of liquid valve capillaries

(2) Insufficient amount of refrigerant (including trouble resulting from an insufficient initial charge

and from gas leakage)

(3) Blocking of low-pressure parts caused by intrusion of foreign objects (moisture, scale, etc.)

(4) Crossing (tubing or PCB connectors) with the other compressor thermistor

(5) Expansion valve operation failure

(6) Accumulation of refrigerant at stopped outdoor units

(7) Compressor discharge sensor failure

(8) PCB failure (A/D conversion failure)

(9) Electrical noise

Check (1) Clogging of capillaries

Trouble: Compressor discharge temperature does not decrease even when the liquid valve

is ON.

Check: When the liquid valve is operating and the liquid valve is ON, check that the

secondary side of the liquid capillaries is cold.

(2) Insufficient refrigerant

Trouble: Liquid effectiveness is poor.

Check: Check whether or not the superheating temperature is declining if the evaporator

mechanical valve is opened to 300 pulses or more (after checking for foreign object

intrusion).

(3) Foreign object intrusion

Trouble: Liquid valve effectiveness is poor.

Check: Check that there is no difference in the condensation or frost conditions between

the strainer primary-side and secondary-side tubing.

(4) Crossed thermistor

Trouble: The discharge temperature of the other compressor is high although only this

compressor is operating.

When the liquid valve turns ON, the discharge temperature of the other compressor

decreases.

(5) Accumulation of refrigerant in stopped outdoor units

Trouble: • System is OK when all outdoor units are operating, however symptoms of

insufficient gas occur when a certain outdoor unit is stopped.

• Condensation or frost is visible up to the top of the accumulator of the stopped

outdoor unit.

• After an outdoor unit stops, there is the sound of refrigerant flowing into an outdoor

unit that was stopped for a long time.

• When an outdoor unit starts after being stopped for a long time, the start is

accompanied by much vibration.

Check: • Representative parts include the liquid capillaries (secondary side of capillaries will

be cool during cooling operation), mechanical valve, mechanical valve bypass check

valve (sound of refrigerant flow can be heard, and stops when the liquid valve is

closed), hot gas defrost valve (if valve secondary side remains hot even after much

time has passed, be careful not to mistake transmitted heat for a valve failure).

• Ice is growing on the lower parts of some outdoor unit heat exchangers but not on

others.

Because this trouble may occur even in outdoor units with a high operating rate

under conditions of insufficient gas, caution is needed.

(6) Sensor failure

Check: • This alarm is likely to occur when wiring is partially cut. (It is difficult to identify, even

when continuity is checked.) The detected discharge temperature is high.

• Although such conditions rarely occur, a P02 alarm is likely if the detected discharge

temperature is low.

• Replace the sensor with another discharge sensor and compare the temperature

conditions.

(7) If the cause is still unknown after checking the above, then it is possible that electrical noise

is the cause of the trouble.

Correction (1) Replace the sensor.

(2) Replace the outdoor unit PCB.

(3) Correct the problem locations.

Example All of the probable causes

Notes Operates continuously for a set length of time.

Indicates 2.5 minutes or longer for an inverter unit and 30 seconds or longer for a constant-

speed compressor.