CTV-PRC007-EN10

Factory Testing for

Assured Performance

To prove that your chiller will perform as

promised, Trane offers factory

performance testing, which you can

witness.

Trane provides laboratory-grade,

calibrated performance testing on

ARI approved test loops that proves the

performance of the chiller tailored to

your application. The test provides:

•

Confirmed efficiency

•

Confirmed capacity

•

Smooth trouble-free start-up confirmed

through factory testing and

commissioning of both chiller and

controls

Trane believes centrifugal chiller testing

is so important that we invested over $2

million in CenTraVac testing facilities.

Testing is in accordance with ARI

Standard 550/590 and calibration of

instrumentation meets or exceeds the

National Institute of Standards

Technology (NIST).

The industry has responded to the

demand for more efficient chillers by

developing machines with component

mix-matching and many money saving

options. It’s possible that with the

thousands of component combinations

available, a specific chiller combination

may be laboratory tested for the first

time.

Trane offers two levels of CenTraVac

performance testing:

•

A performance test at design

conditions plus a certified test report.

•

A customer-witnessed performance

test at design conditions plus a certified

test report.

Trane is part of the ARI 550/590

certification program. The selection

program and machines bear the ARI seal

of approval. Performance testing is a key

part of this program. While the

certification program is technically

sound, a factory run test, with your

machine on the test stand, is still the best

way to confirm machine performance

and a trouble-free start-up.

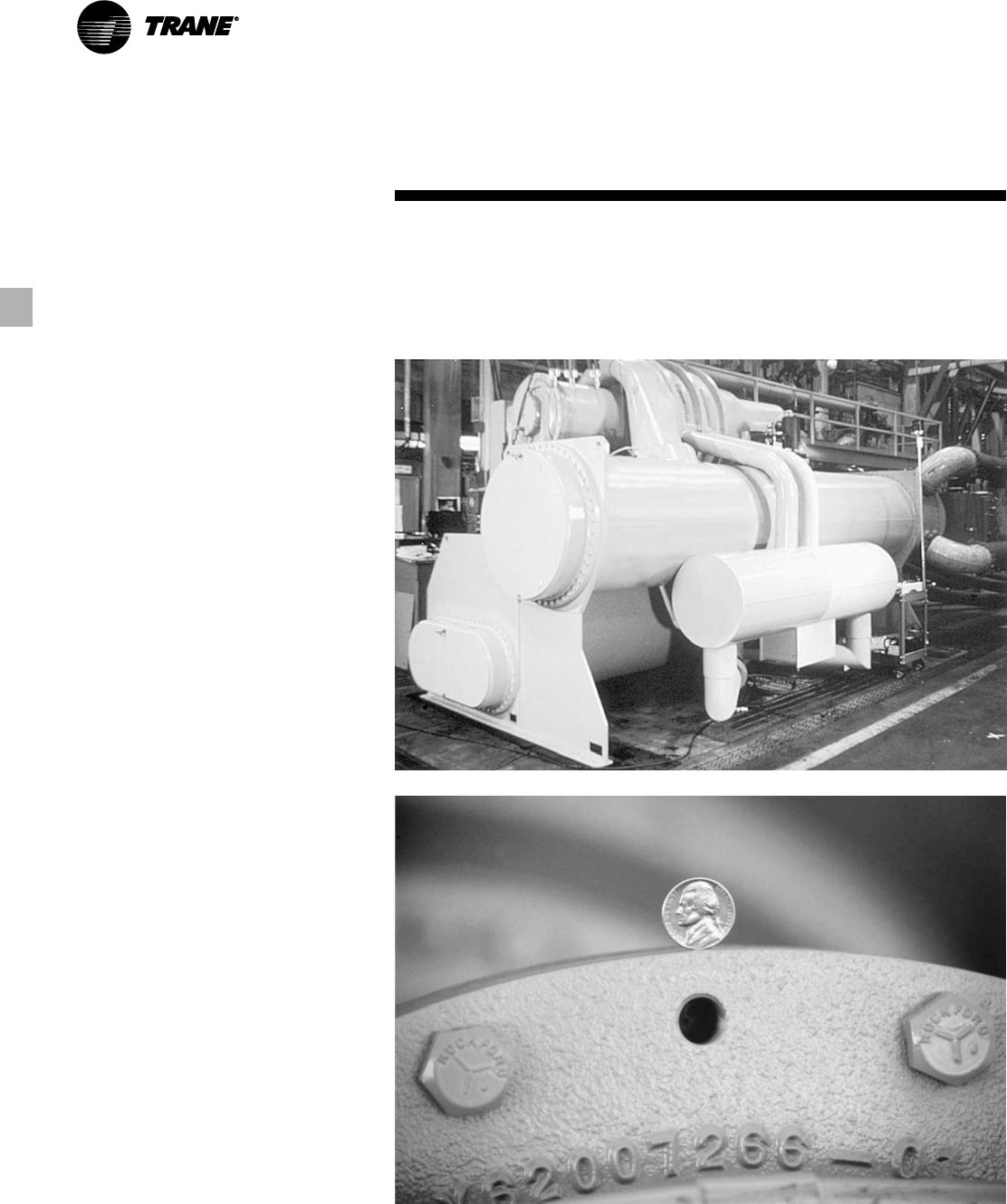

During customer witnessed performance tests of Trane CenTraVac chillers, a nickel

can be balanced on the edge of the compressor-motor assembly, demonstrating the

extremely low vibrations generated by the unit while operating at full and part load

conditions.

The single package design of the

CenTraVac chiller allows testing of each

assembled chiller at the factory. Actually

all components including the evaporator,

condenser, compressor and control

panel are tested before final assembly.

After assembly, performance testing of

the chiller can confirm proper operation

and virtually eliminate jobsite start-up

problems.

Features and

Benefits

Factory

Performance

Testing