21

CTV-PRC007-EN

System

Options

Auxiliary

Condenser (Cont.)

Controls

The auxiliary condenser was designed

for simplicity of operation. Machine load,

water flow rate, and temperature

determine the amount of heat recovered.

There are no controls needed for heating

water temperature because no attempt

is made to maintain a specific hot water

temperature in or out of the auxiliary

condenser.

Operation

The auxiliary condenser is a factory-

mounted, separate, shell and tube heat

exchanger available on water-cooled

CenTraVac chillers.

Because hot refrigerant gas always

migrates to the area of lowest

temperature, auxiliary condenser

operation is simple. As hot gas leaves

the compressor, it is free to flow to the

auxiliary condenser or the standard

condenser. Since water entering the

auxiliary condenser is normally colder

than that entering the standard

condenser, the auxiliary condenser will

have a lower bundle temperature and

will attract the refrigerant gas. The

auxiliary condenser will recover as much

heat as the machine cooling load,

heating water temperature, and flow rate

will allow. All remaining heat will

automatically be rejected through the

standard condenser to the atmosphere

through the cooling tower. No controls

are needed to balance heat rejection in

the two condensers.

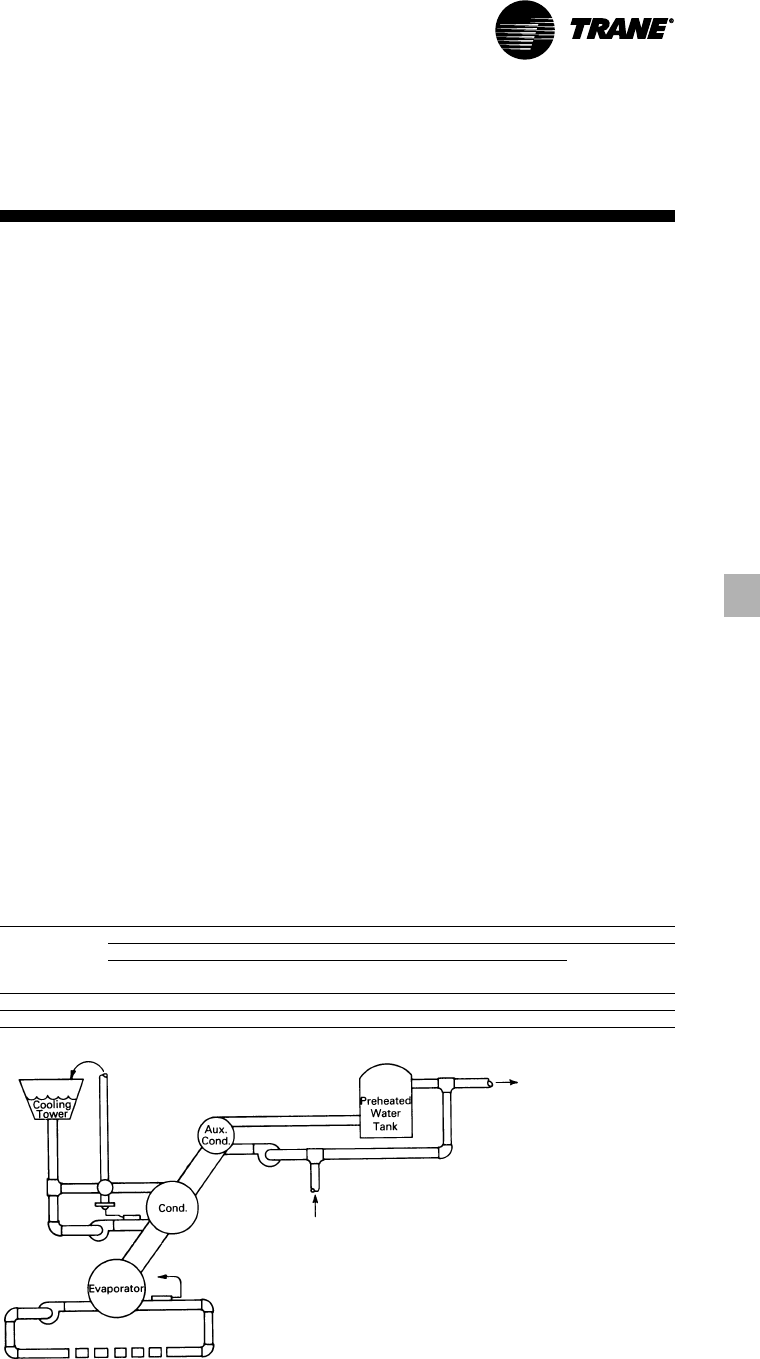

Good system design will include a

heated water bypass to ensure that

water does not circulate through the

auxiliary condenser when the chiller is

de-energized. There are several ways to

bypass the auxiliary condenser. When

the hot water system is installed as

shown in the figure below, the bypass is

automatic if the heating water pump is

interlocked with the chiller compressor

motor.

Another bypass arrangement is to install

a diverting valve. When interlocked with

the compressor motor, this valve diverts

the heating water flow to the

conventional heating system whenever

the chiller is not operating. These are

only examples of the many ways of

accomplishing a bypass.

Contact your local Trane sales office for

further specific information.

Table O-1 — Auxiliary Condenser Flow Limits and Connection Sizes

Auxiliary Two Pass

Condenser Inter Enhanced Smooth Bore Connection

Bundle Minimum Maximum Minimum Maximum Size

Size Gpm Gpm Gpm Gpm (In)

Standard 74 276 70 258 5

Large 121 453 115 423 5