CTV-PRC007-EN24

Simultaneous Heating and Cooling

The Trane Heat Recovery CenTraVac

™

chiller is an excellent choice for

applications requiring simultaneous

heating and cooling. CenTraVac models

save energy by recovering heat normally

rejected to the atmosphere and putting

that energy to use providing space

heating, building hot water or process

hot water. This heat is provided at a

fraction of conventional heating systems

cost. A heat recovery CenTraVac can

provide 95 to 120°F hot water.

An advanced computer selection

program chooses a heat recovery

condenser to match your needs. Two

separate condenser shells are used with

the Heat Recovery CenTraVac chiller. The

heating circuit and cooling tower circuit

are separate, preventing cross

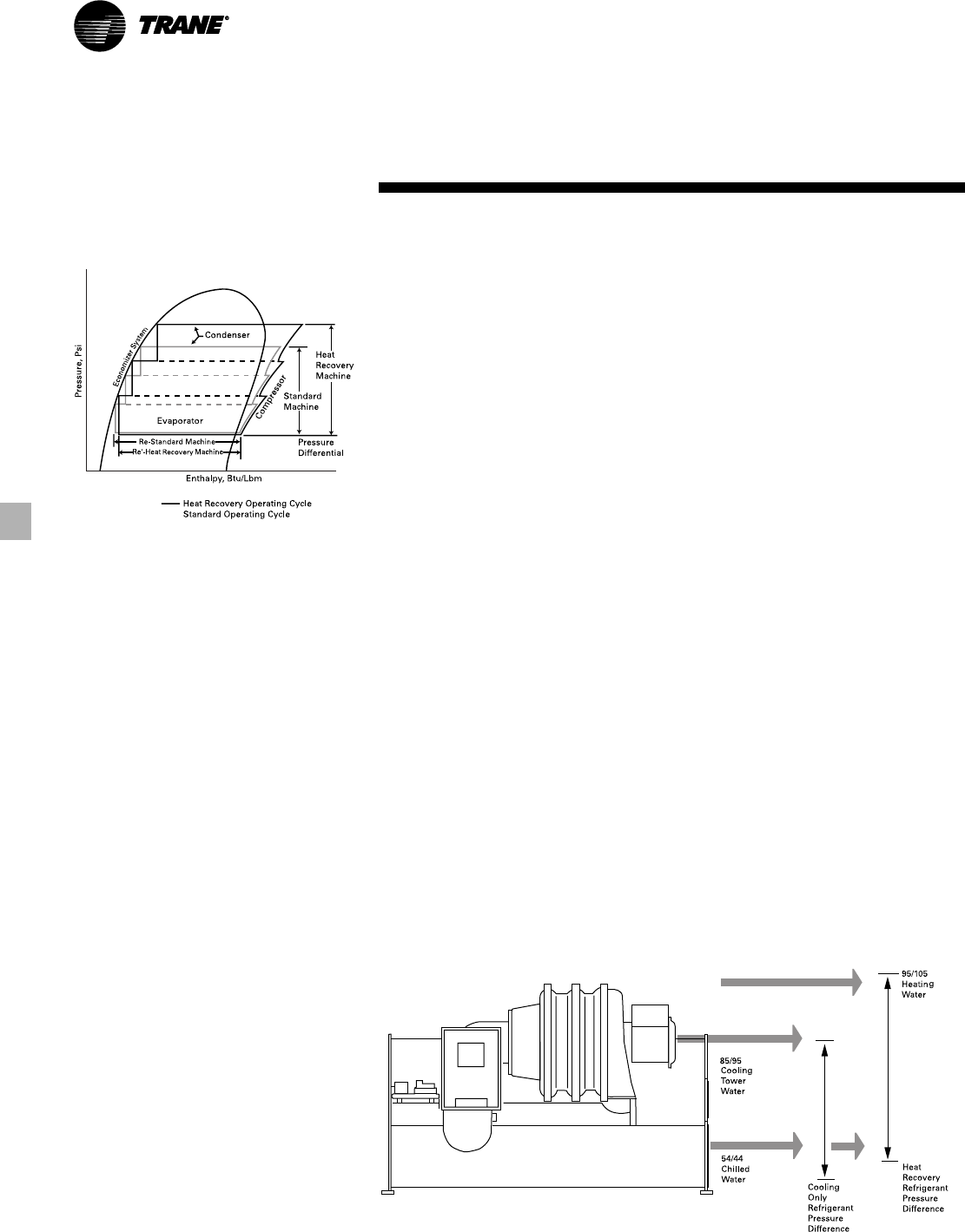

Figure O-8 — Refrigerant Pressure Difference

Figure O-7 — Typical Operating Cycles

System

Options

Heat Recovery

(Cont.)

contamination. Refrigerant gas from the

compressor flows into both condenser

shells allowing heat rejection to one or

both condenser water circuits.

The reliability of the Heat Recovery

CenTraVac chiller has been proven in

installations around the world. This

option is completely factory packaged.

To further reduce the system energy

requirements, the following design

considerations should be incorporated

into any heat recovery system.

System Design Considerations

Heating Water Temperatures and

Control — It is always desirable to use as

low a heating water temperature as the

application allows. Experience has

shown that a design heating water

temperature of 105 to 110°F can satisfy

most heating requirements. Lower

heating water temperatures increase the

chiller operating efficiency both in the

heating mode and in the cooling mode.

In general, the heat recovery power

consumption will increase 7 to 14

percent for every 10°F increase in the

design heating water temperature. A

consideration which is just as important

as the design heating water temperature

is how that temperature is controlled. In

most cases, the heating water

temperature control should be designed

to maintain the return heating water

temperature. By allowing the supply

water temperature to float, the mean

water temperature in the system drops

as the chiller load decreases and less

heat is rejected to the condenser. As the

mean heating water temperature drops,

so does the refrigerant condensing

temperature and pressure difference

which the compressor is required to

produce at part load. This increases the

unloading range of the compressor.

When the supply heating water

temperature to the building system is

maintained and the return heating water

temperature to the condenser is allowed

to float, the mean heating water

temperature actually rises as the chiller

load decreases and less heat is rejected

to the condenser. As Figure

O-8 illustrates, when the compressor

unloads, the pressure difference that it

must oppose to prevent surging remains

essentially the same, while the

compressor’s capability to handle the

pressure difference decreases.

Therefore, the unit’s capability to unload

without the use of hot gas bypass is

reduced.

Hot gas bypass artificially increases the

load on the compressor (cfm of

refrigerant gas) by diverting refrigerant

gas from the condenser back to the

compressor. Although hot gas bypass

increases the unit’s power consumption

by forcing the compressor to pump

more refrigerant gas, it will increase the

heat available to recover for those

applications where significant heating

loads remain as the cooling load

decreases.