11

CTV-PRC007-EN

Design Simplicity

Impellers are keyed directly to the motor

shaft for high reliability and performance

and low life-cycle costs.

Reliable Motor Cooling

The motor is engulfed in liquid

refrigerant to provide efficient, complete

cooling at all load conditions. This

system is reliable and easy to maintain.

Fixed Orifice Flow Control

For proper refrigerant flow control at all

load conditions, the CenTraVac design

incorporates the Trane patented fixed

orifice system. It eliminates float valves,

thermal expansion valves and other

moving parts. Since there are no moving

parts, reliability is increased.

Quiet Operation

With only one moving component — the

rotor and impeller assembly — the Trane

low speed, direct drive design operates

exceptionally quietly. The smoothly

rotating CenTraVac compressor is

inherently quieter than other compressor

types. Typical CenTraVac chiller sound

measurements are among the quietest in

the industry. Trane can guarantee sound

levels with factory testing and

measurements in accordance with

ARI standard 575.

The Reliability Standard

Just as a multi-stage turbine is more

efficient than a single stage turbine, the

CenTraVac multi-stage compressors are

more efficient and reliable than single-

stage designs.

Direct Drive Design — No Gear Losses

The direct drive compressor operates

without speed increasing gears, thus

eliminating gear energy losses.

Compressors using gears suffer mesh

losses and extra bearing losses in the

range of three to five percent at full load.

Since these losses are fairly constant

over the load range, increasingly larger

percentage losses result as load

decreases.

Multiple Stages of Compression

The compressor operates more

efficiently over a wide range of

capacities, virtually eliminating the need

for energy wasting hot gas bypass as

typically found on single stage chillers.

The radial component of velocity

determines the ability of the chiller to

resist interruption of smooth refrigerant

flow when operating at light loads and

with high condensing temperatures. This

interruption in flow and unstable

operation, called “surge” is avoided with

the two-stage design.

Inlet Guide Vanes

Part load performance is further

improved through use of moveable

designed variable inlet guide vanes. Inlet

guide vanes improve performance by

throttling refrigerant gas flow to exactly

meet part load requirements and by

prerotating refrigerant gas for optimum

entry into the impeller. Prerotation of

refrigerant gas minimizes turbulence and

increases efficiency.

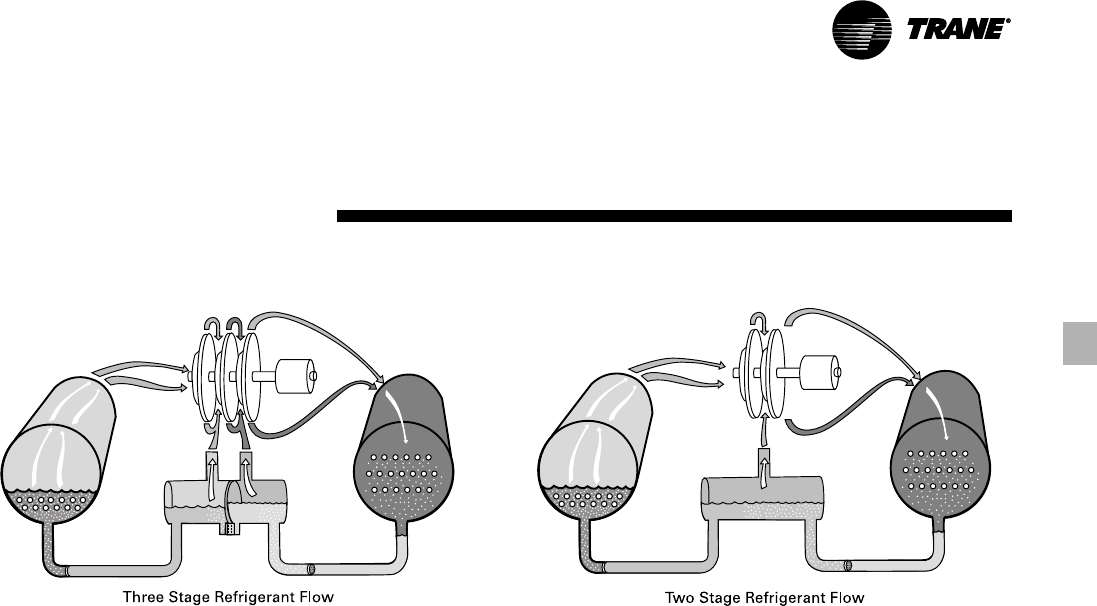

Two-Stage Economizer

The CVHE/CVHG CenTraVac chiller has a

two-stage economizer — providing up to

seven percent greater efficiency than

designs with no economizer. Since the

CVHE/CVHG uses three impellers, it is

possible to flash refrigerant gas at two

intermediate pressures between the

evaporator and condenser pressures,

significantly increasing chiller efficiency.

This improvement in efficiency is not

possible in single-stage chillers since all

compression is done by one impeller.

Single Stage Economizer

The CVHF CenTraVac chiller has a single-

stage economizer — providing up to 4

1

/2

percent greater efficiency than designs

with no economizer.

Since the CVHF CenTraVac uses two

impellers, it is possible to flash

refrigerant gas at an intermediate

pressure between the evaporator and

condenser pressures, significantly

increasing chiller efficiency. This

improvement in efficiency is not possible

in single-stage chillers since all

compression is done by one impeller.

Features and

Benefits

The CenTraVac

™

Chiller Operating Cycle

Refrigeration

Cycle