CTV-PRC007-EN14

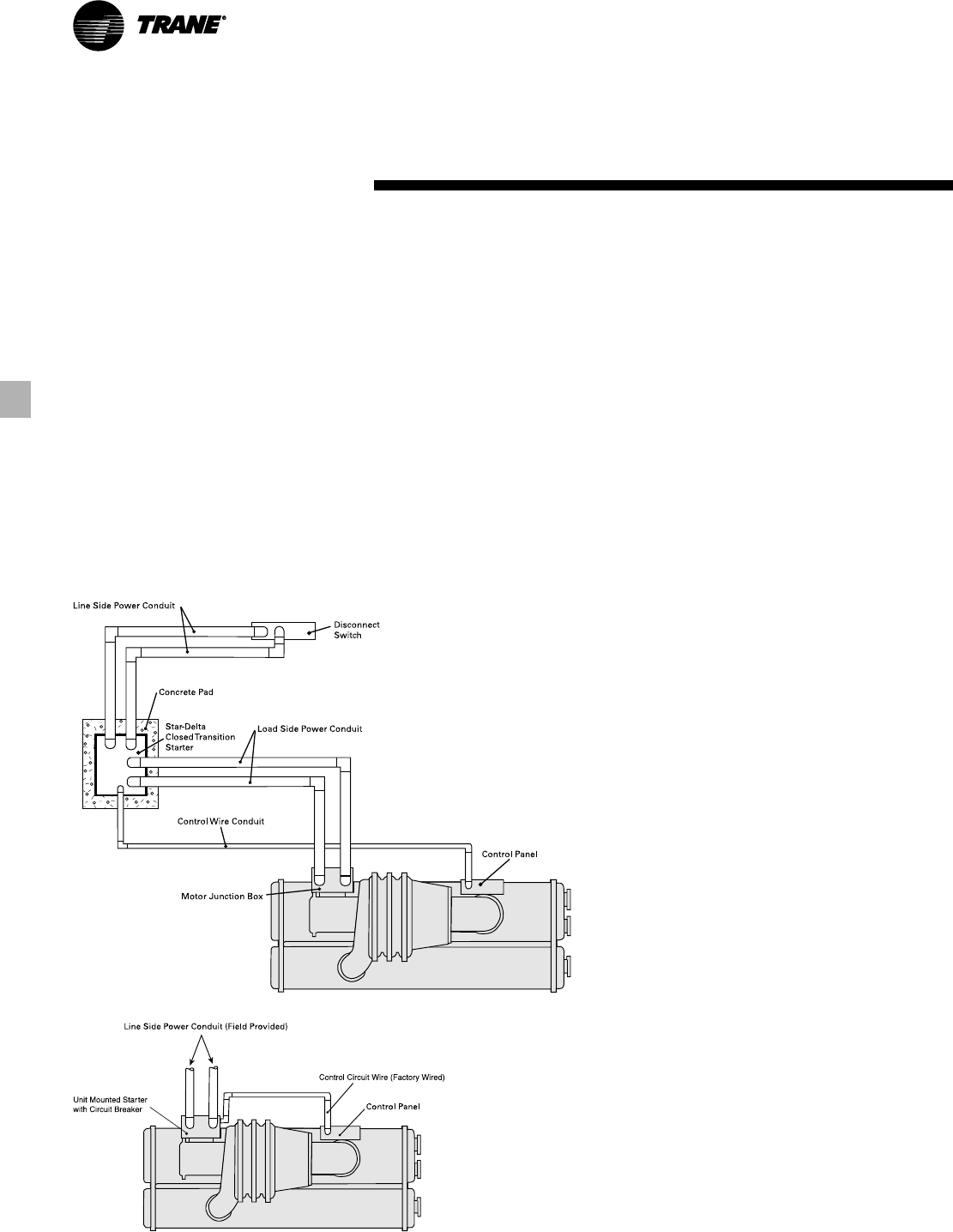

Figure O-2 – Typical Equipment Room Layout – Unit-Mounted Star-Delta Starter

Figure O-1 – Typical Equipment Room Layout – Conventional Remote Star-Delta Starter

•

System Design Time Cost Savings

System design time is reduced, since

all starter components and

interconnecting wiring are pre-

engineered and selected.

•

Complete package available with

Agency Approval

•

Application

The Trane unit mounted starter can be

applied on low voltage (600 volts) and

below applications up to

approximately 1300 tons capacity. To

determine the unit mounted starter to

be used with a particular selection, it is

necessary to know the current draw of

the compressor motor. The starter

current draw must be greater than, or

equal to, the compressor motor

current draw.

•

Reliability

The unit mounted starter is a star-delta

closed transition electromechanical

starter. Motor starters of this

configuration have proven reliability in

thousands of centrifugal chiller

applications around the world. The

proven electromechanical concept plus

the use of industrial quality

components makes the CenTraVac unit

mounted starter dependable in all kinds

of service applications.

Unit

Options

Unit Mounted

Starter (Cont.)

Operation

The unit mounted starter is a star (wye)

delta, closed transition, reduced voltage

starter. When starting and during

acceleration, the motor is connected in

its wye configuration. Because of this

arrangement the voltage applied to the

motor windings is reduced to one

divided by the square root of three or

0.58 times line voltage. This reduction in

winding voltage results in a reduction in

inrush current. The inrush current is 0.33

times the full voltage locked rotor current

rating of the motor. The accelerating

torque of the motor is also reduced to

0.33 times the full voltage torque rating.

This is sufficient to fully accelerate the

compressor motor. The unit control

panel monitors motor current during

operation via current transformers

located in the starter enclosure. When

during acceleration the line current

drops to approximately 0.85 times rated

load current, transition is initiated. The

closed transition feature provides for a

continuous motor current flow during

transition by placing resistors in the

circuit momentarily. This prevents

buildup of damaging torques to the

system during this period. With the

completion of transition, the motor

windings are connected in the delta

configuration with full line voltage.

Three precision current transformers

monitor phase current. Contactor

position and various voltage signals

provide extensive interlocking between

the starter and the microcomputer in the

CenTraVac

™

control panel. All logic and

subsequent instruction originate in the

unit control panel. Protection against the

following starter defects is provided:

•

High motor current (starting and

running)

•

Improper starter circuitry

•

Excessive accelerating time

•

Incomplete starting sequence

•

Loss of phase

•

Phase amperage unbalance

•

Phase reversal

•

Distribution fault

Features

The Trane CenTraVac Unit Mounted

Starter includes the following standard

features:

•

NEMA 1 enclosure, designed to

accommodate padlock

•

3 KVA control power transformer with

120V secondary

•

Fused 120V control circuit

•

3-phase incoming line terminals

•

6 output load terminals factory-

connected to the motor