35

LIQUID CHARGING METHOD — Add charge to the unit

through the liquid line service valve. Never charge liquid into

the low-pressure side of the system.

1. Close liquid line ball valve (30MPA only).

2. Connect a refrigerant cylinder loosely to the high flow

Schraeder valve connection on the liquid line. Purge the

charging hose and tighten the connections.

3. Open the refrigerant cylinder valve.

4. If the system has been dehydrated and is under vacuum,

break the vacuum with refrigerant gas. For R-410A, build

up system pressure to 101 psig and 32 F (697 kPa and

0° C). Invert the refrigerant cylinder so that the liquid re-

frigerant will be charged.

5. a. For complete charge of 30MPW units, follow

charging by weight procedure. When charge is

nearly full, complete the process by observing the

sight glass for clear liquid flow while the unit is

operating. The use of sight glass charging is valid

only when unit is operating at full capacity.

b. For complete charge of 30MPA units or where

refrigerant cylinder cannot be weighed, follow the

condenser manufacturer’s charging procedure or

follow charging by sight glass procedure. The use

of sight glass charging is valid only when unit is

operating at full capacity.

6. a. The 30MPA condenserless units are shipped

with a nitrogen holding charge. After installation

with the field-supplied system high side, the com-

plete system should be evacuated and charged per

the condenser manufacturer’s charging procedure

or charged until the sight glass is clear (with the

unit running at full capacity). To achieve maxi-

mum system capacity, add additional charge equal

to the difference between the condenser optimal

charge and the condenser minimum charge, which

can be obtained from the charge data provided in

the condenser installation instructions.

b. To ensure maximum performance of 30MPW

units, raise the compressor saturated discharge

temperature (SDT) to approximately 100 F

(37.8 C) by throttling the condenser water intake.

Add charge until there is approximately 9 to 12° F

(5.0 to 6.6° C) of system subcooling (SDT minus

actual temperature entering the thermostatic

expansion valve).

Operating Limitations

TEMPERATURES (See Table 29 for 30MP standard tem-

perature limits).

High Cooler Leaving Chilled Water (Fluid) Temperatures

(LCWT) — During start-up with cooler the LCWT should not

be above approximately 60 F (16 C).

Low Cooler LCWT

— For standard units with fresh water,

the LCWT must be no lower than 40 F (4.4 C). For standard

units with a proper brine solution, the LCWT must be no lower

than 32 F (0° C). If the unit is the factory-installed optional

medium temperature brine unit, the cooler LCWT can go

down to 15 F (–9.4 C).

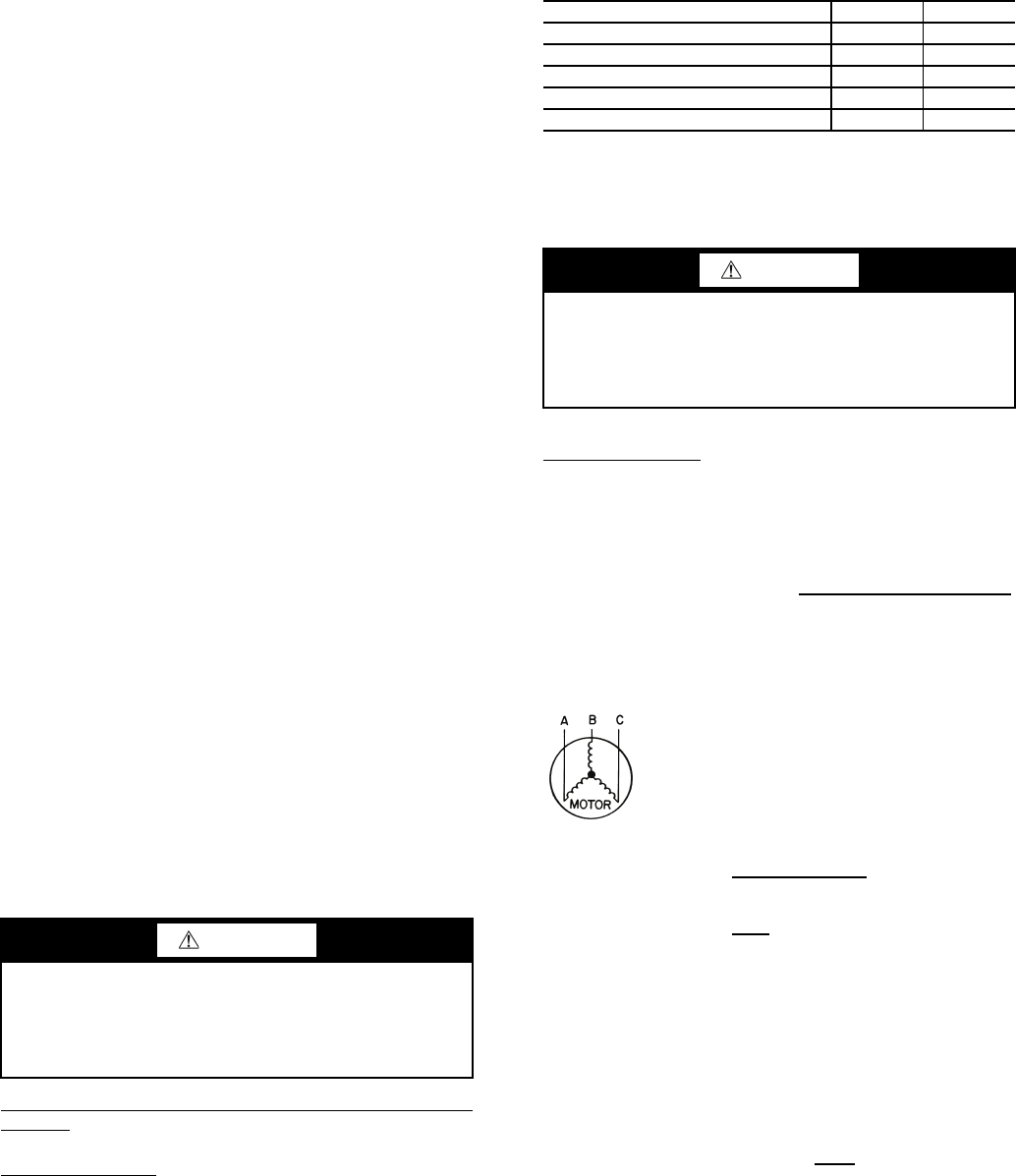

Table 29 — Temperature Limits for

Standard 30MP Units

LEGEND

*For sustained operation, EWT should not exceed 85 F (29.4 C).

†Unit requires modification below this temperature.

VOLTAGE — ALL UNITS

Main Power Supply

— Minimum and maximum acceptable

supply voltages are listed in the Installation Instructions.

Unbalanced 3-Phase Supply Voltage — Never operate a motor

where a phase imbalance between phases is greater than 2%.

To determine percent voltage imbalance:

The maximum voltage deviation is the largest difference

between a voltage measurement across 2 legs and the average

across all 3 legs.

Example: Supply voltage is 240-3-60.

AB = 243 v

BC = 236 v

AC = 238 v

1. Determine average voltage:

2. Determine maximum deviation from average voltage:

(AB) 243 – 239 = 4 v

(BC) 239 – 236 = 3 v

(AC) 239 – 238 = 1 v

Maximum deviation is 4 v.

3. Determine percent voltage imbalance:

CAUTION

Do not operate with cooler leaving chiller water (fluid)

temperature (LCWT) below 32 F (0° C) for standard units

with proper brine solution or 40 F (4.4 C) for the standard

units with fresh water, or below 15 F (–9.4 C) for units fac-

tory built for medium temperature brine.

TEMPERATURE LIMIT F C

Maximum Condenser LWT

140 60

Minimum Condenser EWT

70 21

Maximum Cooler EWT*

95 35

Maximum Cooler LWT

70 21

Minimum Cooler LWT†

40 4

EWT —

Entering Fluid (Water) Temperature

LWT —

Leaving Fluid (Water) Temperature

CAUTION

Medium temperature brine duty application (below 32 F

[0° C] LCWT) for chiller normally requires factory modifi-

cation. Contact your Carrier representative for applicable

LCWT range for standard water-cooled chiller in a specific

application.

% Voltage Imbalance = 100 x

max voltage deviation

from avg voltage

average voltage

Average voltage =

243 + 236 + 238

3

=

717

3

= 239

% Voltage Imbalance = 100 x

4

239

= 1.7%

a30-4979