43

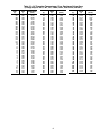

Table 35 — 10K Thermistor Temperature (°C) vs. Resistance/Voltage Drop

(For SPT)

Strainer — Periodic cleaning of the required field-installed

strainer is required. Pressure drop across strainer in excess of

3 psi (21 kPa) indicates the need for cleaning. Normal (clean)

pressure drop is approximately 1 psi (6.9 kPa). Open the

blowdown valve to clean the strainer. If required, shut the chill-

er down and remove the strainer screen to clean. When strainer

has been cleaned, enter ‘YES’ for Strainer Maintenance Done

(Run Status

PM

S.T.MN.

Replacing Defective Modules — The Comfort-

Link

™

replacement modules are shown in Table 36. If the main

base board (MBB) has been replaced, verify that all configura-

tion data is correct. Follow the Configuration mode table and

verify that all items under sub-modes UNIT, OPT1 and OPT2

are correct. Any additional field-installed accessories or op-

tions (RSET, SLCT sub-modes) should also be verified as well

as any specific time and maintenance schedules.

Refer to the Start-Up Checklist for 30MP Liquid Chillers

(completed at time of original start-up) found in the job folder.

This information is needed later in this procedure. If the check-

list does not exist, fill out the current information in the Config-

uration mode on a new checklist. Tailor the various options and

configurations as needed for this particular installation.

1. Check that all power to unit is off. Carefully disconnect

all wires from the defective module by unplugging its

connectors.

2. Remove the defective module by removing its mounting

screws with a Phillips screwdriver, and removing the

module from the control box. Save the screws later use.

3. Verify that the instance jumper (MBB) or address switch-

es (all other modules) exactly match the settings of the

defective module.

NOTE: Handle boards by mounting standoffs only to

avoid electrostatic discharge.

4. Package the defective module in the carton of the new

module for return to Carrier.

5. Mount the new module in the unit’s control box using a

Phillips screwdriver and the screws saved in Step 2.

TEMP

(C)

VOLTAGE

DROP

(V)

RESISTANCE

(Ohms)

–32 4.762 200,510

–31 4.748 188,340

–30 4.733 177,000

–29 4.716 166,342

–28 4.700 156,404

–27 4.682 147,134

–26 4.663 138,482

–25 4.644 130,402

–24 4.624 122,807

–23 4.602 115,710

–22 4.580 109,075

–21 4.557 102,868

–20 4.533 97,060

–19 4.508 91,588

–18 4.482 86,463

–17 4.455 81,662

–16 4.426 77,162

–15 4.397 72,940

–14 4.367 68,957

–13 4.335 65,219

–12 4.303 61,711

–11 4.269 58,415

–10 4.235 55,319

–9 4.199 52,392

–8 4.162 49,640

–7 4.124 47,052

–6 4.085 44,617

–5 4.044 42,324

–4 4.003 40,153

–3 3.961 38,109

–2 3.917 36,182

–1 3.873 34,367

0 3.828 32,654

1 3.781 31,030

2 3.734 29,498

3 3.686 28,052

4 3.637 26,686

5 3.587 25,396

6 3.537 24,171

7 3.485 23,013

8 3.433 21,918

9 3.381 20,883

10 3.328 19,903

11 3.274 18,972

12 3.220 18,090

13 3.165 17,255

14 3.111 16,464

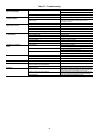

TEMP

(C)

VOLTAGE

DROP

(V)

RESISTANCE

(Ohms)

15 3.056 15,714

16 3.000 15,000

17 2.944 14,323

18 2.889 13,681

19 2.833 13,071

20 2.777 12,493

21 2.721 11,942

22 2.666 11,418

23 2.610 10,921

24 2.555 10,449

25 2.500 10,000

26 2.445 9,571

27 2.391 9,164

28 2.337 8,776

29 2.284 8,407

30 2.231 8,056

31 2.178 7,720

32 2.127 7,401

33 2.075 7,096

34 2.025 6,806

35 1.975 6,530

36 1.926 6,266

37 1.878 6,014

38 1.830 5,774

39 1.784 5,546

40 1.738 5,327

41 1.692 5,117

42 1.648 4,918

43 1.605 4,727

44 1.562 4,544

45 1.521 4,370

46 1.480 4,203

47 1.439 4,042

48 1.400 3,889

49 1.362 3,743

50 1.324 3,603

51 1.288 3,469

52 1.252 3,340

53 1.217 3,217

54 1.183 3,099

55 1.150 2,986

56 1.117 2,878

57 1.086 2,774

58 1.055 2,675

59 1.025 2,579

60 0.996 2,488

61 0.968 2,400

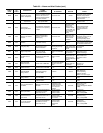

TEMP

(C)

VOLTAGE

DROP

(V)

RESISTANCE

(Ohms)

62 0.940 2,315

63 0.913 2,235

64 0.887 2,157

65 0.862 2,083

66 0.837 2,011

67 0.813 1,943

68 0.790 1,876

69 0.767 1,813

70 0.745 1,752

71 0.724 1,693

72 0.703 1,637

73 0.683 1,582

74 0.663 1,530

75 0.645 1,480

76 0.626 1,431

77 0.608 1,385

78 0.591 1,340

79 0.574 1,297

80 0.558 1,255

81 0.542 1,215

82 0.527 1,177

83 0.512 1,140

84 0.497 1,104

85 0.483 1,070

86 0.470 1,037

87 0.457 1,005

88 0.444 974

89 0.431 944

90 0.419 915

91 0.408 889

92 0.396 861

93 0.386 836

94 0.375 811

95 0.365 787

96 0.355 764

97 0.345 742

98 0.336 721

99 0.327 700

100 0.318 680

101 0.310 661

102 0.302 643

103 0.294 626

104 0.287 609

105 0.279 592

106 0.272 576

107 0.265 561

WARNING

Electrical shock can cause personal injury and death. Shut

off all power to this equipment during installation. There

may be more than one disconnect switch. Tag all discon-

nect locations to alert others not to restore power until work

is completed.