48

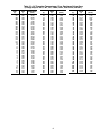

Table 38 — Alarm and Alert Codes (cont)

See legend on page 51.

ALARM/

ALERT

CODE

ALARM

OR

ALERT

DESCRIPTION

WHY WAS THIS

ALARM

GENERATED?

ACTION TAKEN

BY CONTROL

RESET

METHOD

PROBABLE

CAUSE

A116 Alarm

Circuit A Low Cooler

Suction Temperature

Mode 7 caused the com-

pressor to unload 6 consecu-

tive times with less than a

30-minute interval between

each circuit shutdown.

Circuit shut down Manual

Faulty expansion valve, low

refrigerant charge, plugged

filter drier, faulty suction

pressure transducer, low

cooler fluid flow

A122 Alarm

High Pressure Switch

Trip Circuit A

High Pressure A Switch

Input opento MBB

Circuit shut down Manual

Faulty transducer/high

pressure switch.

A126 Alarm

Circuit A High

Discharge Pressure

SCT >Maximum condensing

temperature from operating

envelope

Circuit shut down

Automatic, only

after first 3 daily

occurrences.

Manual reset

thereafter. Read-

ing from OAT sen-

sor must drop 5 F

(2.8 C) before

restart

Faulty transducer/high

pressure switch, low/

restricted condenser

airflow

T133 Alert

Circuit A Low Suction

Pressure

Suction pressure below

34 psig for 8 seconds or

below 23 psig

Circuit shut down

Automatic

restart after first

daily occurrence.

Manual restart

thereafter.

Faulty or plugged EXV, low

refrigerant charge, EXV out

of adjustment, liquid

line valve partially closed

A140 Alert

Reverse Rotation

Detected

Incoming chiller power leads

not phased correctly

Chiller not allowed to

start.

Manual

Reverse any two incoming

power leads to correct. Check

for correct fan rotation first.

A150 Alarm Emergency Stop

CCN emergency stop

command received

Chiller shutdown

without going through

pumpdown.

Automatic once

CCN command for

EMSTOP returns to

normal

CCN Network

command.

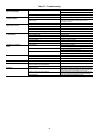

A151 Alarm Illegal Configuration

One or more illegal

configurations exists.

Chiller is not allowed to

start.

Manual once

configuration errors

are corrected

Configuration error.

Check unit settings.

A152 Alarm

Unit Down Due to

Failure

Both circuits are down due

to alarms/alerts.

Chiller is unable

to run.

Automatic once

alarms/alerts are

cleared that pre-

vent the chiller from

starting.

Alarm notifies user

that chiller is 100%

down.

T153 Alert

Real Time Clock

Hardware Failure

Internal clock on MBB fails

Occupancy schedule

will not be used. Chiller

defaults to Local On

mode.

Automatic when

correct clock con-

trol restarts.

Time/Date/Month/

Day/Year not

properly set.

A154 Alarm

Serial EEPROM

Hardware Failure

Hardware failure with MBB

Chiller is unable

to run.

Manual

Main Base Board

failure.

T155 Alert

Serial EEPROM

Storage Failure

Configuration/storage

failure with MBB

No Action Manual

Potential failure of

MBB. Download

current operating

software. Replace

MBB if error occurs again.

A156 Alarm

Critical Serial EEPROM

Storage Failure

Configuration/storage

failure with MBB

Chiller is not allowed

to run.

Manual

Main Base Board

failure.

A157 Alarm A/D Hardware Failure

Hardware failure with

peripheral device

Chiller is not allowed

to run.

Manual

Main Base Board

failure.

T173 Alert

Loss of Communication

with EMM

MBB loses communication

with EMM

4 to 20 mA

temperature reset

disabled. Demand

Limit set to 100%. 4 to

20 mA set point

disabled.

Automatic

Wiring error, faulty

wiring or failed

Energy Management Module

(EMM).

T174 Alert

4 to 20 mA Cooling Set

Point Input Failure

If configured with EMM and

input less than 2 mA or

greater than 22 mA

Set point function

disabled. Chiller

controls to CSP1.

Automatic

Faulty signal

generator, wiring

error, or faulty EMM.

T176 Alert

4 to 20 mA

Temperature Reset

Input Failure

If configured with EMM

and input less than 2 mA or

greater than 22 mA

Reset function

disabled. Chiller

returns to normal set

point control.

Automatic

Faulty signal

generator, wiring

error, or faulty EMM.

T177 Alert

4 to 20 mA Demand

Limit Input Failure

If configured with EMM and

input less than 2 mA or

greater than 22 mA

Demand limit function

disabled. Chiller

returns to 100%

demand limit

control.

Automatic

Faulty signal

generator, wiring

error, or faulty EMM.