16

CDVX Series Direct Vent Gas Fireplace

20012253

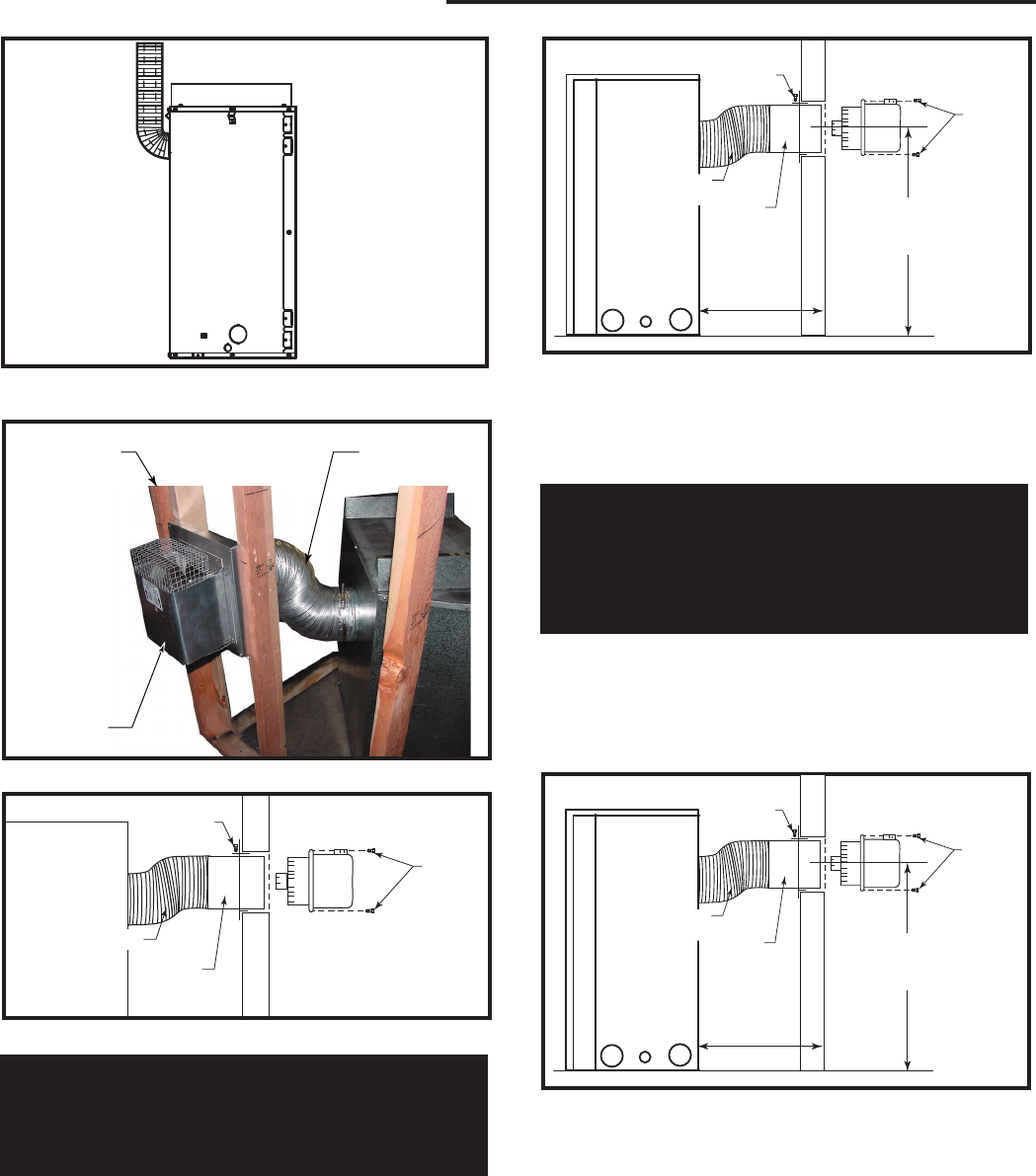

Fig. 21 Bend flex pipe up 90° as close to fireplace as pos-

sible.

FP1604

Do Not Exceed

45° Bend

Corner

Framing

Termination

FP1606

Fig. 22 Rear view of corner installation.

Screw

Collar

Screws

FP1605

Fig. 23 Secure collar in place, slide termination into collar.

Flex Vent

Rear Wall Vent Application

* Exterior Outside Wall

13” to 20” (330 - 508 mm)

From Rear of Unit * Using Flex Venting Kit

1. Determine the location of the termination. (Fig. 24)

IMPORTANT: Vent must have a 2¹⁄₂” (64 mm) rise

for this application.

2. Locate the hole 24¹⁄₂” (622 mm) off the floor. This

is the center line of the termination. Refer to “Rear

Wall Installation Twist Lock Pipe” section.

Screw

Screws

Flex Vent

Collar

FP1605a

Fig. 24 The centerline of the termination must be 24¹⁄₂”

(622 mm) off the floor.

24¹⁄₂”

(622 mm)

13” - 20”

(330 - 508 mm)

3. Proceed with Step 3 of “Rear Wall Vent Application

*Exterior Outside Wall 20” to 32” (508-813 mm) from

Rear of Unit” section (below).

Rear Wall Vent Application

* Exterior Outside Wall

20” - 32” (508 - 813 mm)

From Rear of Unit * Using Flex Vent Kit

7TCD45KT

1. Determine where the termination is to be installed.

(Fig. 25)

2. Locate the hole 27¹⁄₄” (692 mm) off the floor. This

is the center line of the termination. Refer to “Rear

Wall Installation Twist Lock Pipe” section.

Screw

Screws

Flex Vent

Collar

FP1605a

Fig. 25 The centerline of the termination must be 27¹⁄₄”

(692 mm) off the floor.

27¹⁄₄”

(692 mm)

20” - 32”

(508 - 813 mm)

3. Mount the flex pipe assembly to the fireplace collars

and twist the collar that the flex pipe is attached to

onto the fireplace.

4. Once the collar is twisted onto the fireplace collar,

secure with a screw through the tab. (Fig. 19)

5.

While sliding the fireplace into position, lift up the end

of the flex pipe and slip it through the firestop. *Be

careful not to extend the flex too much. The flex pipe