24

CDVX Series Direct Vent Gas Fireplace

20012253

1

2

3

4

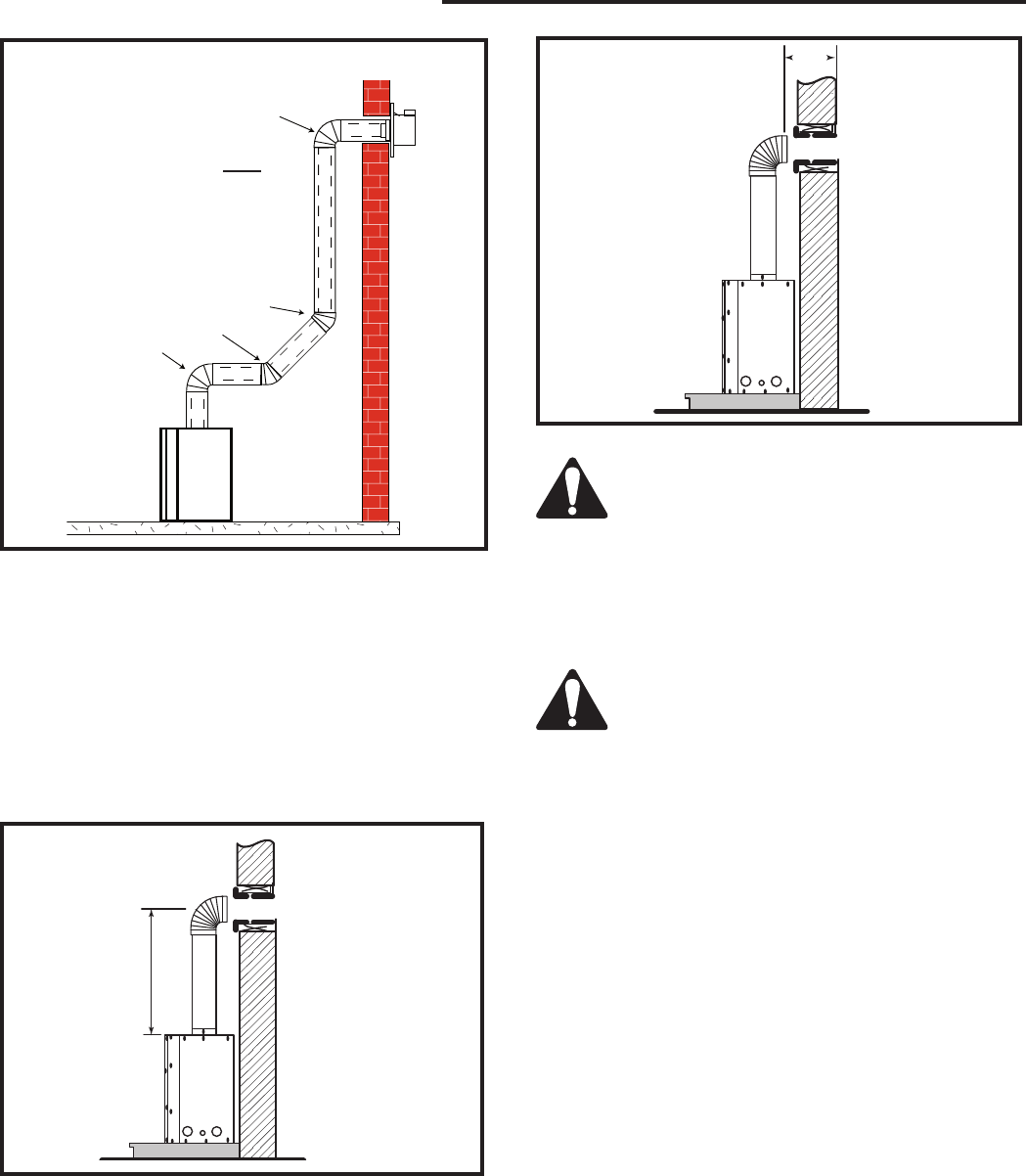

Example:

Elbow 1 = 90°

Elbow 2 = 45°

Elbow 3 = 45°

Elbow 4 = 90°

Total angular variation = 270°

1 + 2 + 3 + 4 = 270°

FP1239

Fig. 48 Maximum number of elbow degrees.

STEP 2

Place fireplace into position. (Fig. 49) Measure the verti

-

cal height (X) required from the base of the flue collars

to the center of the wall opening.

STEP 3

Attach appropriate venting component(s) to the fire

-

place with three (3) screws. (Fig. 50) Follow with the

installation of the inner and outer elbow. Again secure

joints with three (3) sheet metal screws.

X

FP1240

Fig. 49 Vertical height requirement.

STEP 4

Measure the horizontal length requirement including

a 2” (51 mm) overlap, ie from the elbow to the outside

wall face plus 2” (51 mm) (or the distance required if

installing a second 90° elbow). (Fig. 50)

Always install horizontal venting on a level

plane.

STEP 5

Use appropriate length of pipe sections - telescopic or

fixed - and install the horizontal vent sections. The sec-

tions which go through the wall are packaged with the

starter kit, and can be cut to suit if necessary. (Fig. 48)

Sealing the gaps between the vent pipe

and firestop with high temperature sealant

will restrict cold air being drawn in around

fireplace.

STEP 6

Guide the vent terminations 4” and 7” collars into their

respective vent pipes. Double check that the vent pipes

overlap the collars by 2” (51 mm). Secure the termina-

tion to the wall with screws provided and caulk around

the wall plate to weatherproof. (Fig. 52) As an alterna-

tive to screwing the termination directly to the wall you

may also use expanding plugs or an approved exterior

construction adhesive. You may also attach the termi-

nation with screws through the inner body into the 4”

(102 mm) vent pipe however for this method you must

extend the 4” (102 mm) pipe approximately 6” (152 mm)

beyond the outer face of the wall.

Support horizontal pipes every 3’ (914 mm) with metal

pipe straps. Make sure the horizontal vent pipe is in-

stalled on a level horizontal plane.

X

FP1241

Fig. 50 Horizontal length requirement.