28

ENGLISH

II. MAINTENANCE - MONTHLY

A. Check that the oven is cool and the power is disconnected,

as described in the warning at the beginning of this Section.

B. Refer to Part C,

Conveyor Installation, in the Installation

section of this Manual. Then, remove the following compo-

nents from the oven:

Conveyor exit tray

Crumb trays

Chain cover

End plugs

Conveyor assembly

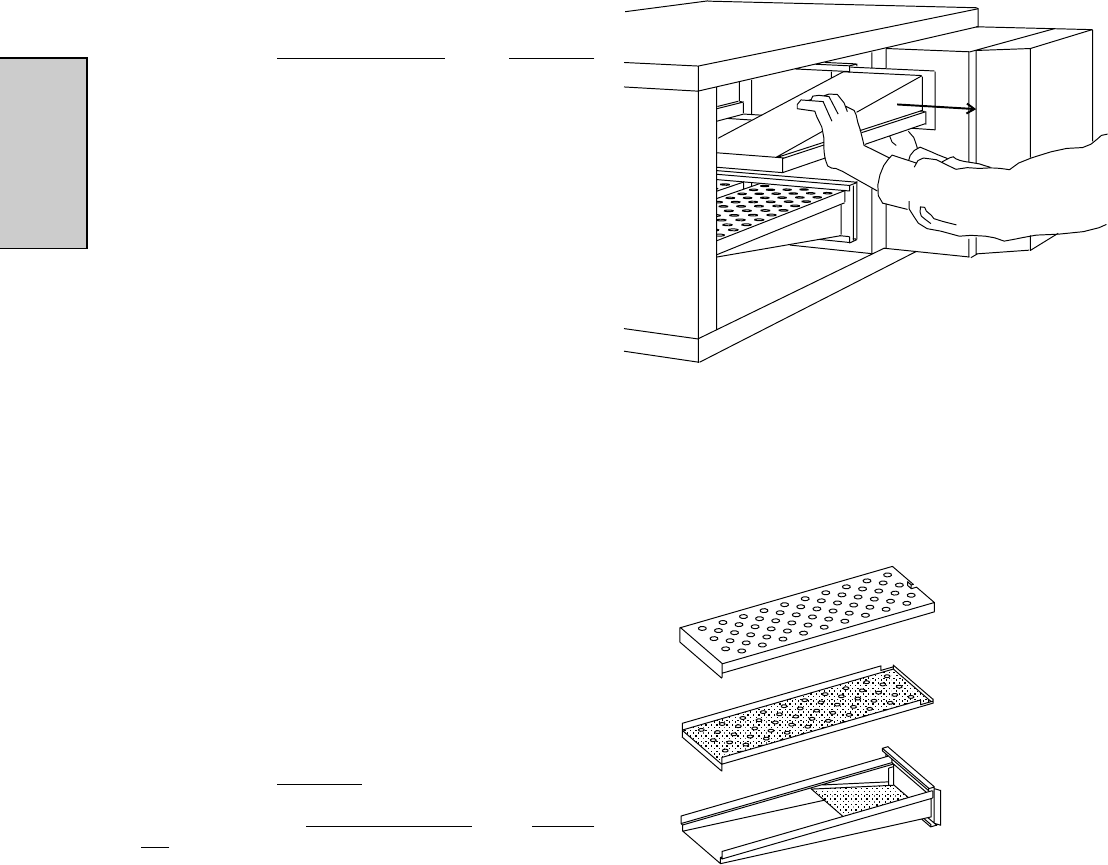

C. Slide the air fingers and blank plates out of the oven, as

shown in Figure 4-2. AS EACH FINGER OR PLATE IS

REMOVED, WRITE A "LOCATION CODE" ON IT WITH A

MARKER to make sure that it can be reinstalled correctly.

Example of markings:

(Top Row) T1 T2 T3 T4

(Bottom Row) B1 B2 B3 B4

D. Disassemble the air fingers. See Figure 4-3. AS EACH

FINGER IS DISASSEMBLED, WRITE THE "LOCATION

CODE" FOR THE FINGER ON ALL THREE OF ITS PIECES.

This will help you in correctly reassembling the air fingers.

CAUTION

Incorrect reassembly of the air fingers will change the

baking properties of the oven.

E. Clean the air finger components and the interior of the

baking chamber using a vacuum cleaner and a damp cloth.

Refer to the boxed warnings at the beginning of this Section

for cleaning precautions.

F. Reassemble the air fingers. Then, replace them in the

oven, using the "location code" as a guide.

G. Install the end plugs on the oven. Then, reinstall the

conveyor.

H. Reattach the drive chain. Replace the chain cover.

I. Check the tension of the conveyor belt as shown in Figure

2-7 (in Section 2,

Installation). The belt should lift between

25-50mm. If necessary, adjust the belt tension using the

procedure in Part C (

Conveyor Installation) in the Installa-

tion section of this Manual.

J. Replace the crumb trays and exit tray onto the oven.

Figure 4-2 - Removing Air Fingers and Plates

Figure 4-3 - Disassembling the Air Fingers

Outer Plate

SECTION 4 - MAINTENANCE

Inner plate

Manifold

III. MAINTENANCE - EVERY 3 MONTHS

A. Check that the oven is cool and the power is disconnected,

as described in the warning at the beginning of this Section.

B. Open the machinery compartment access panel. Vacuum

the inside of the compartment using a shop vacuum.

C. Tighten all electrical control terminal screws.