31

ENGLISH

SECTION 4 - MAINTENANCE

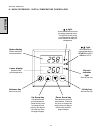

1. Type 2 Conveyor Split Belt Cleaning

a. Refer to Part C,

Conveyor Installation, in the Installation

section of this Manual. Then, remove the following compo-

nents from the oven:

Conveyor exit tray

Crumb trays

Chain cover

End plugs

Conveyor assembly

b. Remove the master links from each conveyor belt. Then,

roll the belts up along the length of the conveyor to remove

them from the frame.

c. Remove the two conveyor adjustment screws from the idler

end of the conveyor frame, as shown in Figure 4-8.

d. Remove the idler shaft assembly from the conveyor.

e. Pull apart the two sections of the idler shaft.

f. Clean the shafts thoroughly using a rag. Then, lubricate

both the extended shaft and the interior of the hollow shaft

using a light food-grade lubricant.

DO NOT lubricate the

shafts using WD40 or a similar product. This can cause the

shafts to wear rapidly.

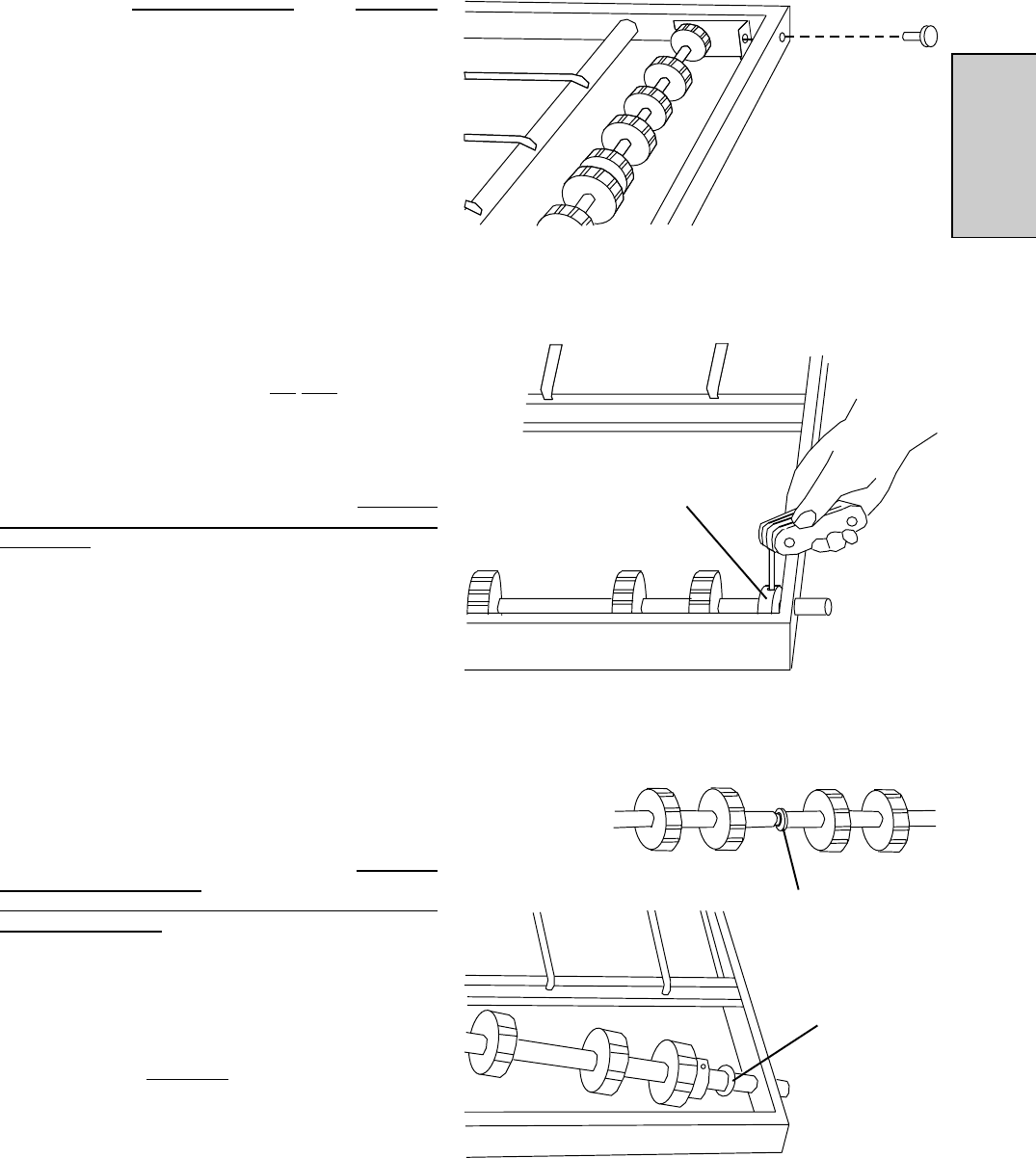

g. Before reassembling the shafts into the conveyor frame,

check that they are oriented properly.

h. Reassemble the idler shaft into the conveyor.

Make sure

that the bronze washer is in place between the two sections

of the shaft. See Figure 4-10.

i. Replace the conveyor adjustment screws as shown in

Figure 4-8. To allow the conveyor belt to be reinstalled later,

do not tighten the screws at this time.

j. Loosen the set screw on both of the conveyor drive sprock-

ets. Then, remove the sprockets from the shaft.

k. Loosen the locking collar set screw, as shown in Figure 4-

9.

l. Push the drive shaft towards the drive sprocket, and lift it

free of the conveyor frame. Then, disassemble and lubri-

cate the two sections of the drive shaft as described for the

idler shaft, above.

m. Before reassembling the shafts into the conveyor frame,

check that they are oriented properly.

n. Reassemble the drive shaft into the conveyor.

Check that

the nylon spacer is in place, as shown in Figure 4-10. Also,

check that the bronze washer is in place between the two

sections of the shaft.

o. Replace the drive sprockets. Reassemble the belts and

master links onto the conveyor.

p. Reinstall the end plugs and conveyor onto the oven.

q. Reattach the drive chains. Replace the chain cover.

r Check the tension of the conveyor belt as shown in Figure

2-18 (in Section 2,

Installation). The belt should lift about

25mm. If necessary, adjust the belt tension by turning the

conveyor adjustment screws.

s. Replace the crumb trays and exit tray onto the oven. Then,

skip ahead to Part E, "Blower Belt."

Figure 4-8 - Split Belt Idler Shaft

Figure 4-9 - Split Belt Drive Shaft

Figure 4-10 - Washer and Spacer

Conveyor

adjustment

screw

Locking collar

Bronze washer on

BOTH idler and

drive shafts

Nylon spacer

on drive shaft

ONLY