Connection to the water inlet

,

Water in the machine must not

be used as drinking water.

^

The machine must be connected to

the water supply in accordance with

local and national water authority

regulations.

^

This machine is constructed to

comply with German water

regulations (DVGW), and may be

connected to a suitable supply

without an extra non-return valve if

national regulations permit.

^ The water pressure (flow rate) must

be a minimum of 0.5 bar (50 kPa).

If the water pressure (flow rate) is

below 2 bar (200 kPa), the filling time

is automatically extended.

The max. permitted static pressure is

10 bar (1000 kPa).

If the water pressure is not in the

range of 0.5 to 10 bar (50-1000 kPa),

the p / 6 indicator light may come

on and the fault code "F..E" will show

in the display. Please contact the

Miele Service Department.

^

The machine is supplied as standard

for connection to a cold (coded blue)

and

a hot (coded red) water supply

up to a max. temperature of 70 °C.

The inlet hoses should be connected

to the stopcocks for the hot and cold

water supplies. The steam condenser

inlet hose (without waterproof

connector) should be connected to

the cold water stopcock.

If there is no hot water connection,

the hot water inlet hose marked red

should also be connected to a cold

water stopcock.

^

Stopcocks with 3/4 BSP male thread

are to be provided on site. They

should be easily accessible so that

the water supply can be turned off

when the machine is not in use.

^

The DN 10 inlet hoses are approx.

1.7 m long terminating in a 3/4 inch

female thread. On no account must

the inlet filters be removed.

^

Large surface area filters are

enclosed in the kit supplied with the

machine for installing between the

stopcock and the inlet hose

(see illustration in "Cleaning and Care

- Water inlet").

,

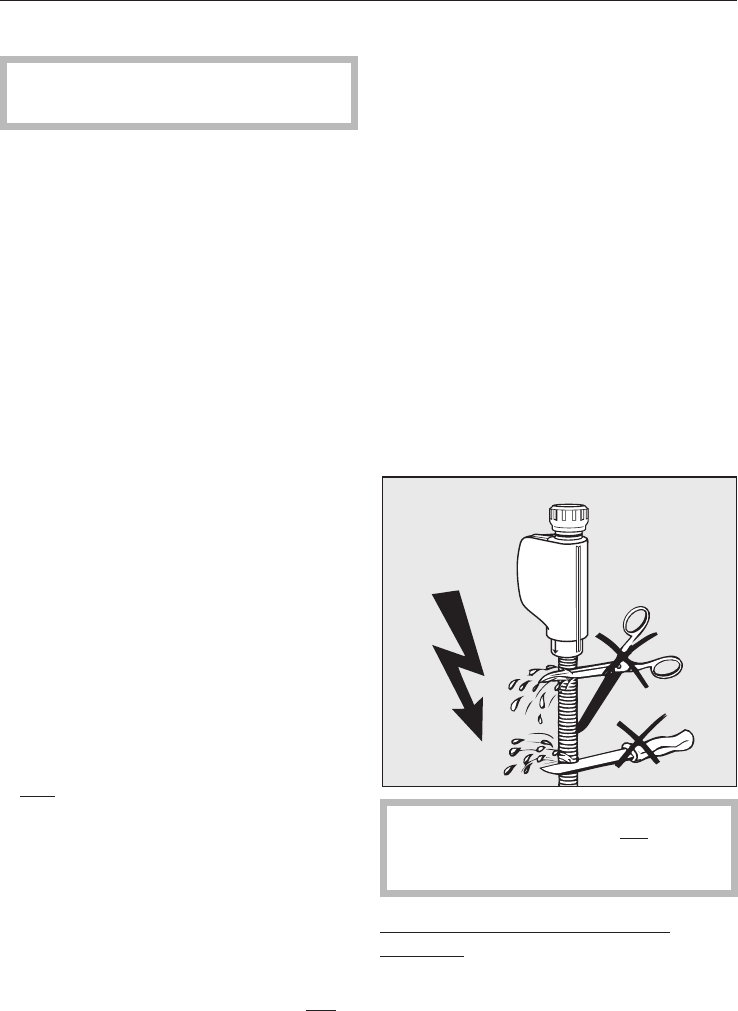

The inlet hoses must not be

shortened or damaged in any way

(see illustration).

See also the installation diagram

supplied.

Plumbing

49