13

CVHE-SVU01E-EN

Overview

Controls Operator Interface

Information is tailored to operators,

service technicians and owners

When operating a chiller, there is

specific information you need on a

day-to-day basis — setpoints, limits,

diagnostic information, and reports.

When servicing a chiller, you need

different information and a lot more

of it — historic and active

diagnostics, configuration settings,

and customizable control algorithms,

as well as operation settings.

By providing two different tools –

one for daily operation and one for

periodic service — everyone has

easy access to pertinent and

appropriate information.

General

Information

DynaView

™

Human Interface

— For the operator

Day-to-day operational information is

presented at the panel. Up to seven

lines of data (English or SI units) are

simultaneously displayed on the ¼

VGA touch-sensitive screen.

Logically organized groups of

information — chiller modes of

operation, active diagnostics,

settings and reports put information

conveniently at your fingertips. See

Operator Interface Section for details.

TechView

™

Chiller Service Tool

— For the service technician or

advanced operator

All chiller status, machine

configuration settings, customizable

limits, and up to 60 active or historic

diagnostics are displayed through

the service tool interface. Without

changing any hardware, we give you

access to the latest and greatest

version of Tracer CH530! A new level

of serviceability using the innovative

TechView

™

chiller service tool, a

technician can interact with an

individual device or a group of

devices for advanced

troubleshooting. LED lights and their

respective TechView

™

indicators

visually confirm the viability of each

device. Any PC that meets the system

requirements may download the

service interface software and Tracer

CH530 updates. For more information

on TechView

™

visit your local Trane

Service company, or The Trane

Company’s website at

www.trane.com.

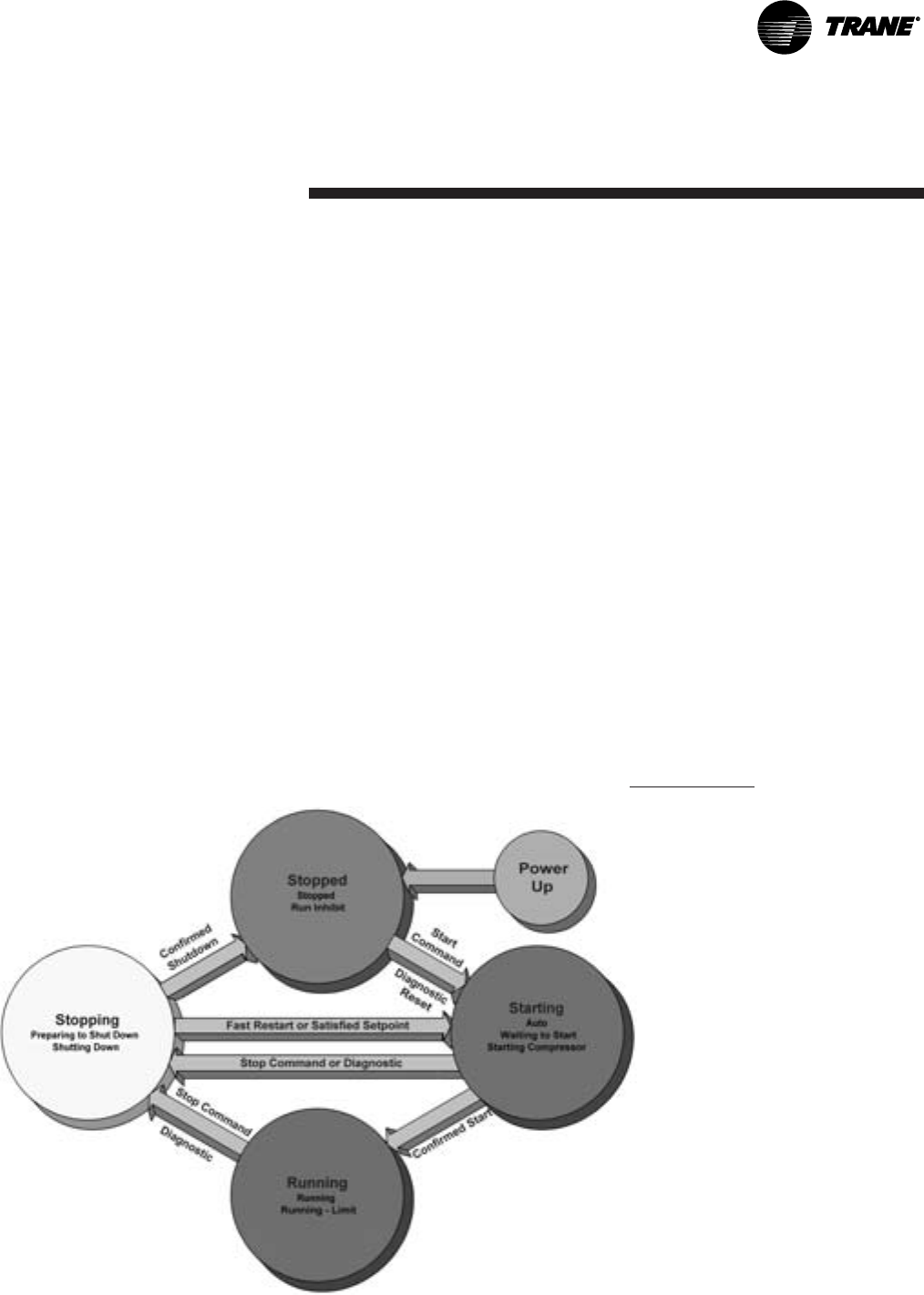

Figure 7. CVHE, CVHF, and CVHG sequence of operation overview